Method for preparing and using multifunctional inorganic fiber facing material

A technology of inorganic fibers and decorative materials, which is applied in the field of building materials products, environmental protection and heat preservation building materials products, and can solve the problems of single, complicated construction process and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

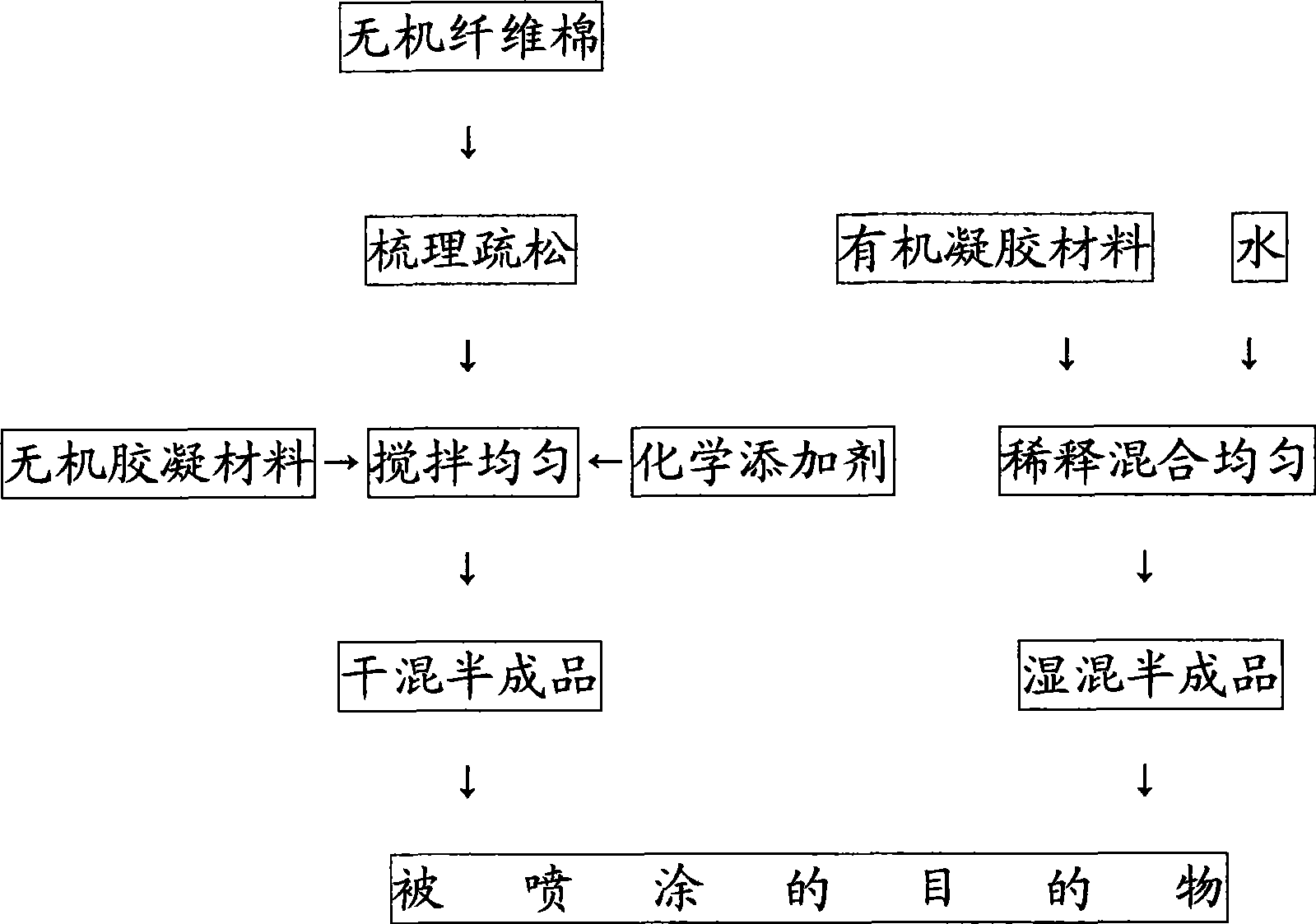

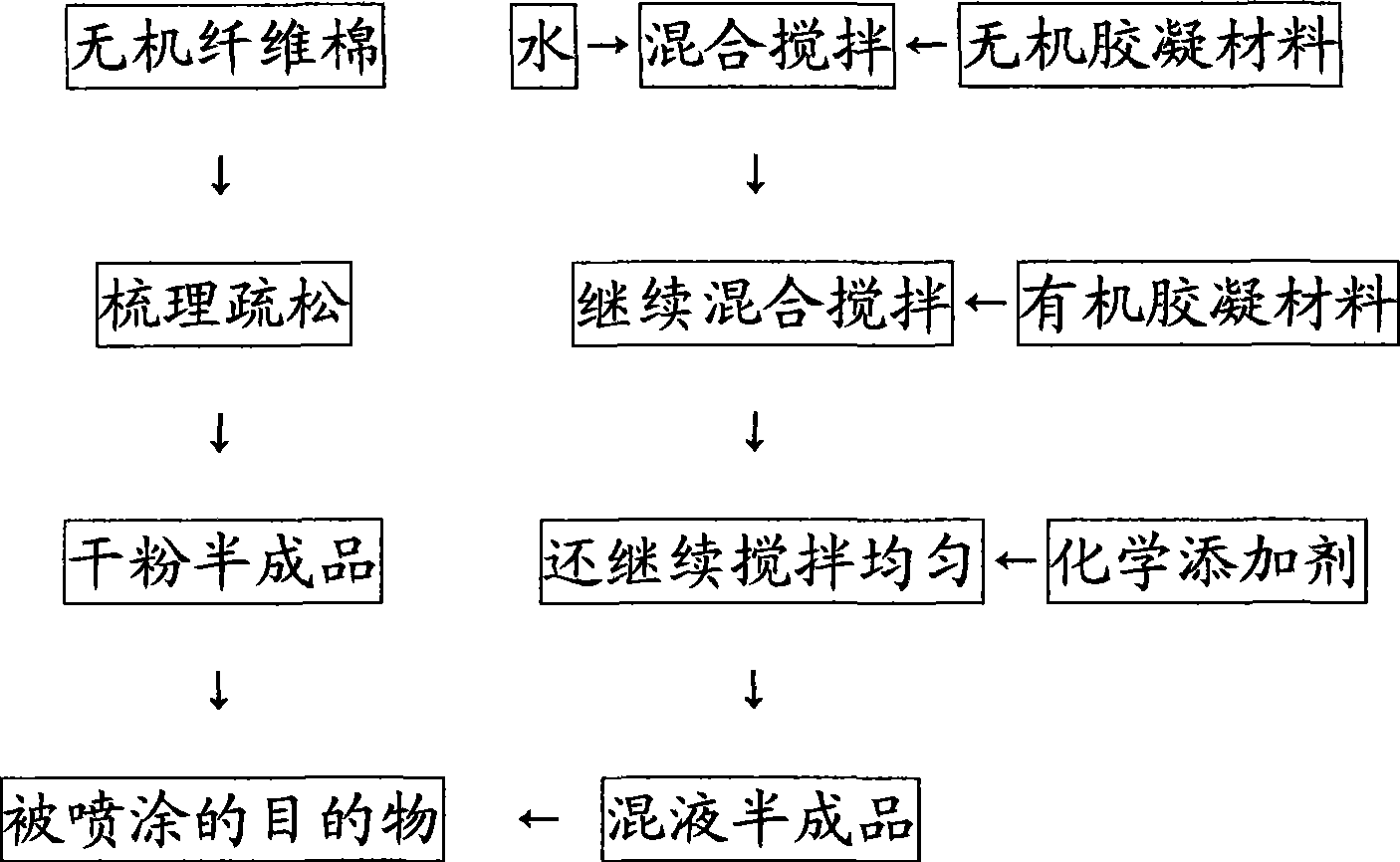

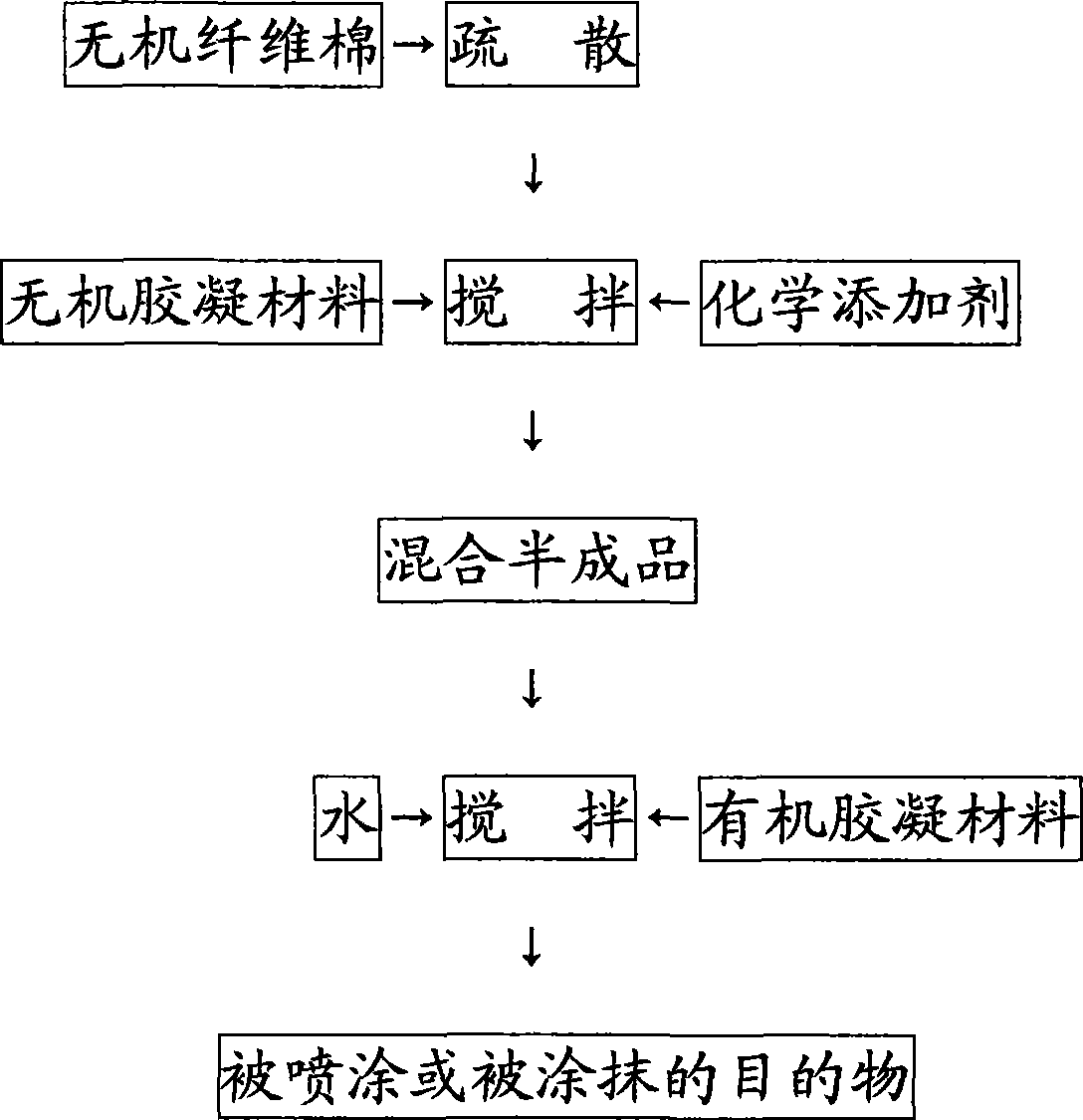

Method used

Image

Examples

specific Embodiment approach 2

[0052] Carry out according to specific embodiment one, just: the raw material that takes weight as unit is mainly made up of 20 kilograms of inorganic fiber cotton, 0.1 kilogram of inorganic gelling material, 0.1 kilogram of organic gelling material, 2 kilograms of chemical additives, 50 kilograms of water and carried out implementation ; also received the expected good results.

specific Embodiment approach 3

[0053] Carry out according to specific embodiment one, just: the raw material with weight as unit is mainly made up of 35 kilograms of inorganic fiber cottons, 8 kilograms of inorganic gelling materials, 10 kilograms of organic gelling materials, 5 kilograms of chemical additives, 70 kilograms of water and carry out implementation ; also received the expected good results.

specific Embodiment approach 4

[0054] Carry out according to specific embodiment one, just: the raw material that takes weight as unit is mainly made up of 25 kilograms of inorganic fiber cottons, 0.5 kilograms of inorganic gelling materials, 0.5 kilograms of organic gelling materials, 3 kilograms of chemical additives, 55 kilograms of waters and carried out implementation ; also received the expected good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com