Tail gas emission filter

An exhaust emission and filter technology, which is applied to exhaust devices, machines/engines, mufflers, etc., can solve the problems of difficult maintenance, small dust holding capacity, inconvenient installation and use, etc., to achieve convenient installation and use, and improve air intake efficiency. , the effect of the best filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

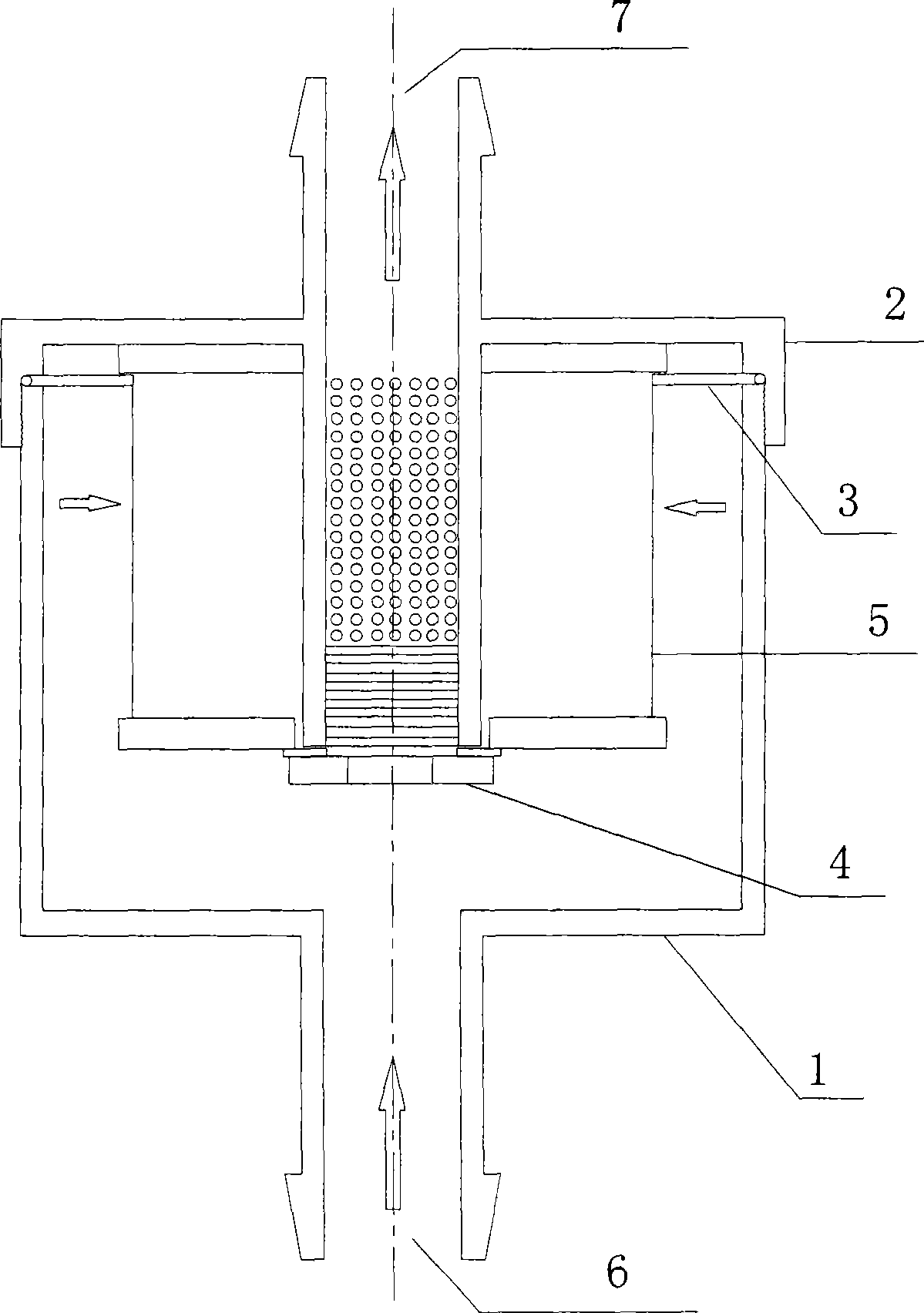

[0011] In this example, refer to figure 1 , the exhaust emission filter includes a base 1 , an upper cover 2 and a filter element 5 . The center of the upper cover 2 is provided with an air outlet interface 7 connected to the air outlet of the filter element 5. The upper cover 2 and the base 1 are connected by a screw thread, and the upper cover 2 and the base 1 are sealed by a sealing ring 3, and the bottom of the base 1 is provided with an inlet. The air end interface 6; the bottom of the filter element 5 is closed and fixed by the fixing screw 4, the filter element 5 uses glass fiber as the filter medium, and the base 1 envelops the filter element 5 as a whole to form a cavity. The sealing ring 3 is an O-ring.

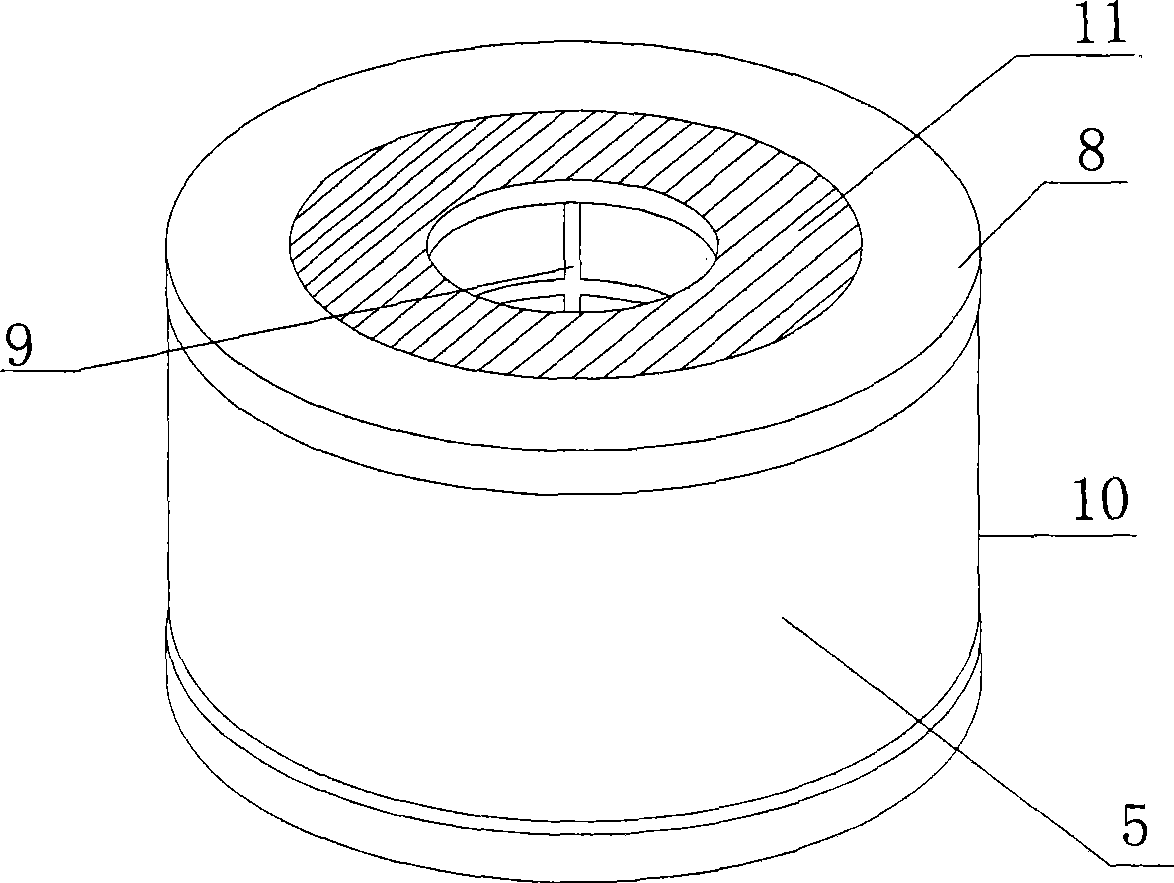

[0012] refer to figure 2 , the filter element 5 is composed of two top covers 8 with a central hole as the air inlet and outlet, a ring structure, a filter medium composed of glass fibers, and a support 9. The top cover 8 and the support 9 are made of high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com