All-year cold supply chiller with natural cooling function

A technology for natural cooling and chillers, which is applied in refrigerators, refrigeration components, refrigeration safety arrangements, etc., can solve the problems of reduced operation reliability, increased energy consumption of units, difficulty in achieving efficient and reliable cooling, and saves operation. Power consumption, energy saving effect is obvious, the effect of avoiding antifreeze problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

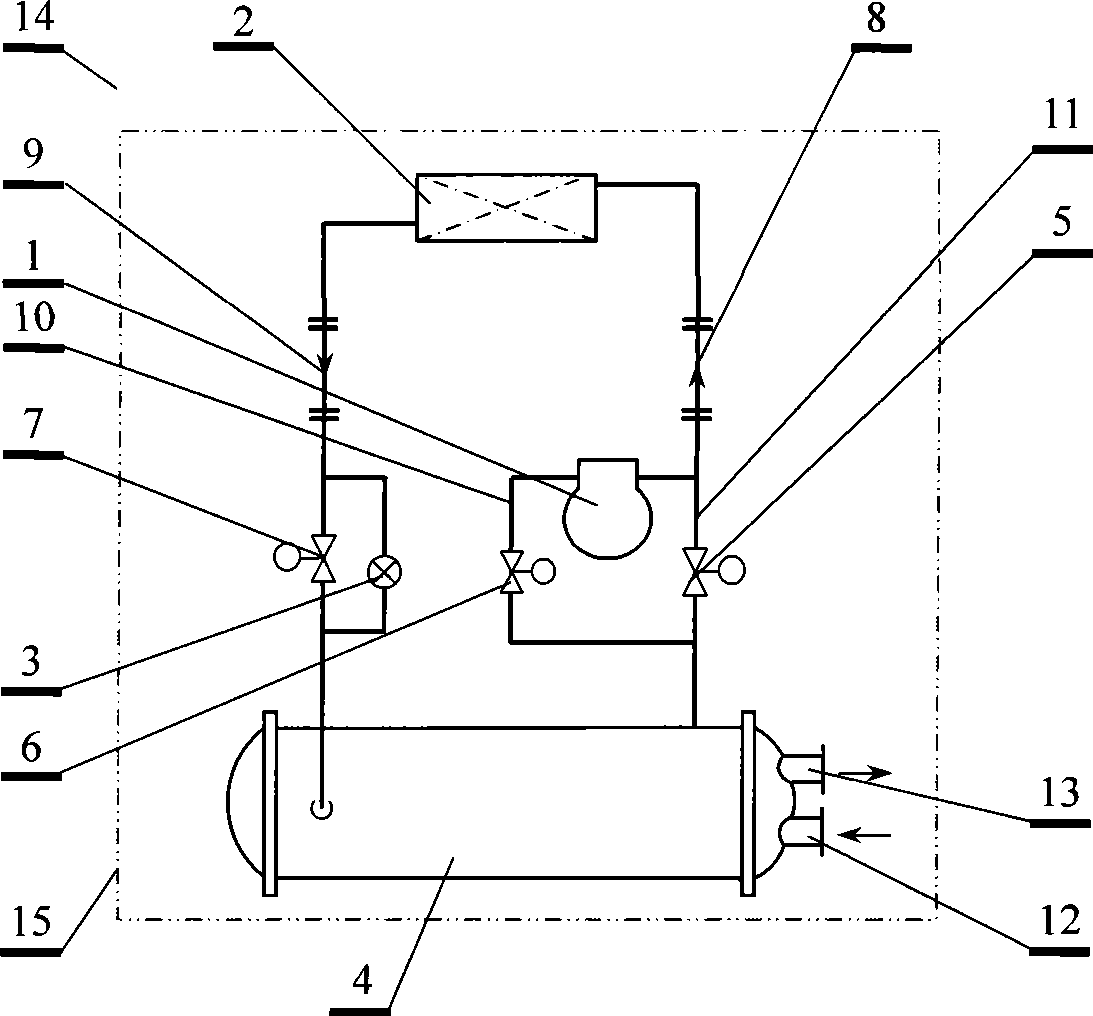

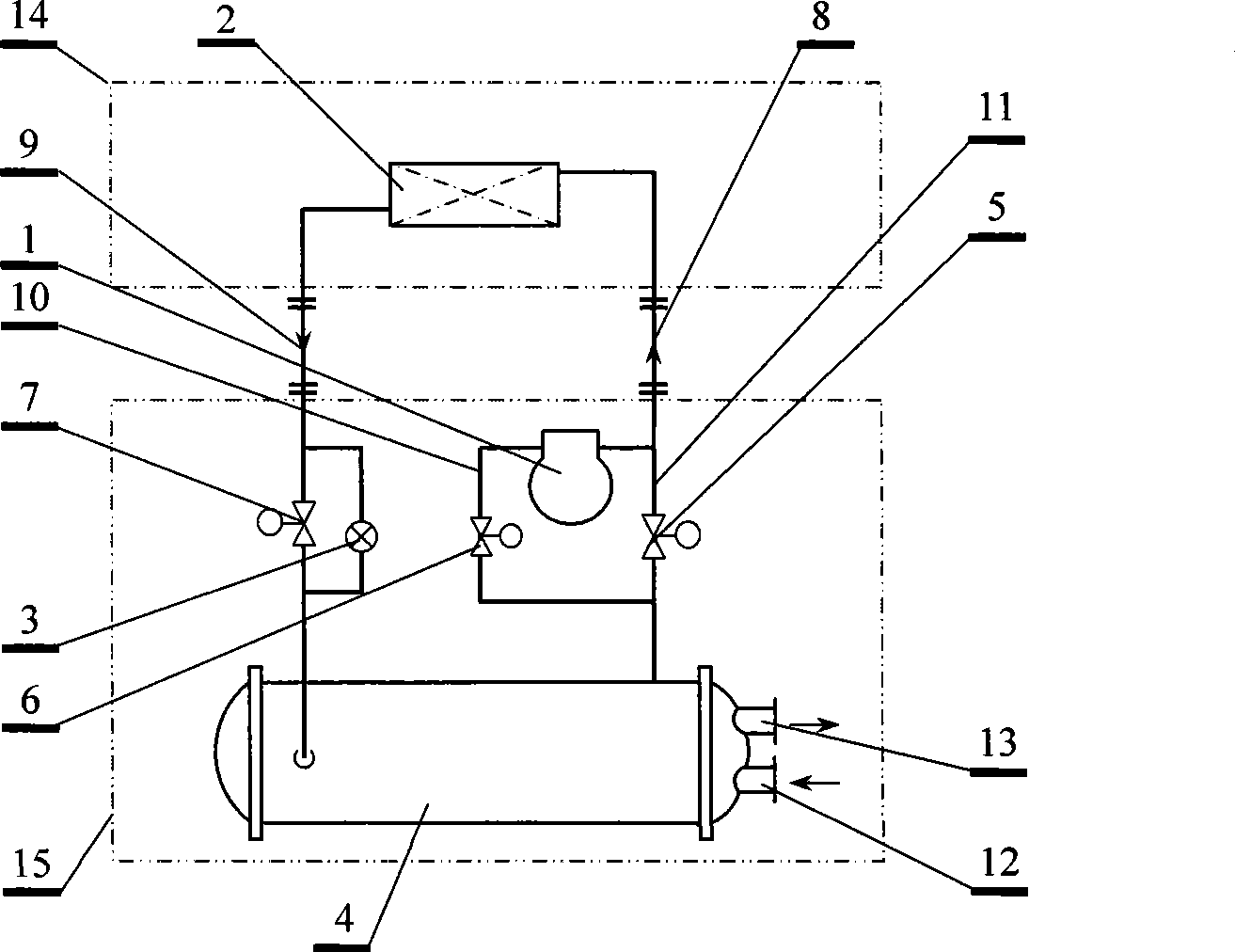

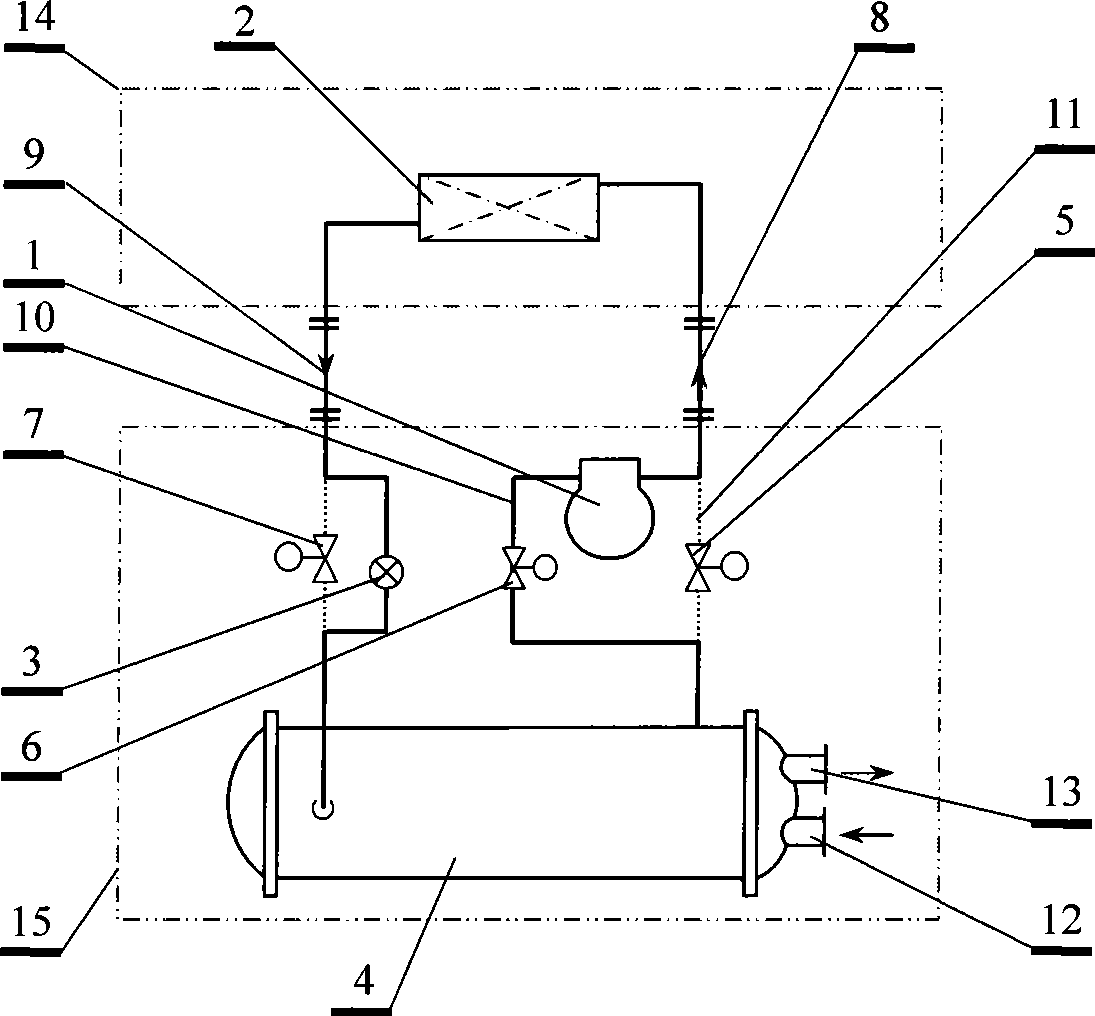

[0022] figure 1 The structural principle diagram of the whole year cooling water chiller with natural cooling function disclosed by the present invention adopts the integral unit. The year-round cooling chiller with natural cooling and cross-season cold storage functions includes a compressor 1, a condenser 2, an evaporator 4, a liquid connecting pipe 9, a throttling device 3 and a gas connecting pipe 8, and is composed of a compressor 1, The condenser 2 is sequentially connected through the liquid connection pipe 9, the throttling device 3, the evaporator 4 and the gas connection pipe 8 to form a vapor compression refrigeration cycle circuit; the heat pipe liquid valve 7 is connected in parallel at both ends of the throttling device 3, and the compressor A refrigerant gas valve 6 is provided on the compressor suction pipe 10 between the suction port of 1 and the outlet of the evaporator 4, and a heat pipe gas valve is provided on the heat pipe branch 11 between the exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com