Spatial carrier based interference confocal measuring device and method

A measurement device, confocal technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of time-consuming, large environmental impact, etc., and achieve the effect of overcoming the difference in surface reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

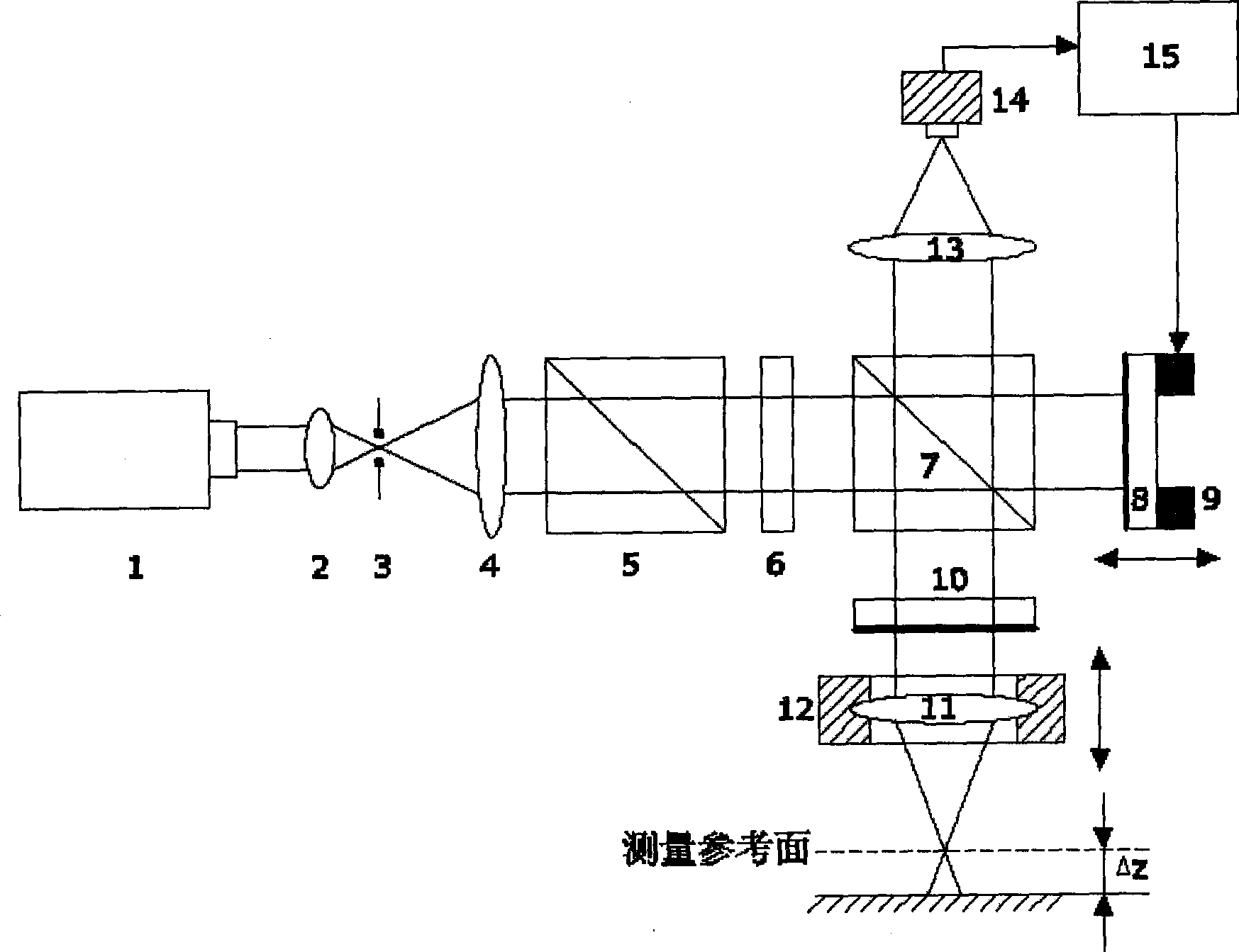

[0024] The present invention is described in detail in conjunction with accompanying drawing:

[0025] Such as figure 1 As shown, the interferometric confocal measurement device based on the space carrier of the present invention includes: a laser 1, a collimating and focusing objective lens 2, a pinhole 3, a collimating beam expanding objective lens 4, a polarizing beam splitter 5, a quarter wave plate 6, Beam splitter 7, detection focusing objective lens 11, second micro-driver 12, collecting objective lens 13; Auxiliary reference mirror 8 and first micro-driver 9 are arranged in sequence behind the beam splitter 7 along the main optical axis direction of laser 1, and main reference mirror 10 is arranged on Between the spectroscope 7 and the detection focusing objective lens 11, at the focal point of the collecting objective lens 13, a CCD camera 14 is placed, and the main control computer 15 is connected with the CCD camera 14 and the first microdriver 9.

[0026] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com