Method and means for producing a magnetically induced indicia in a coating containing magnetic particles

A marking and coating technology, applied in the application of magnetic films to substrates, magnetic coatings, devices for coating liquids on surfaces, etc., can solve the problems of lack of aesthetic feeling and dull appearance of images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

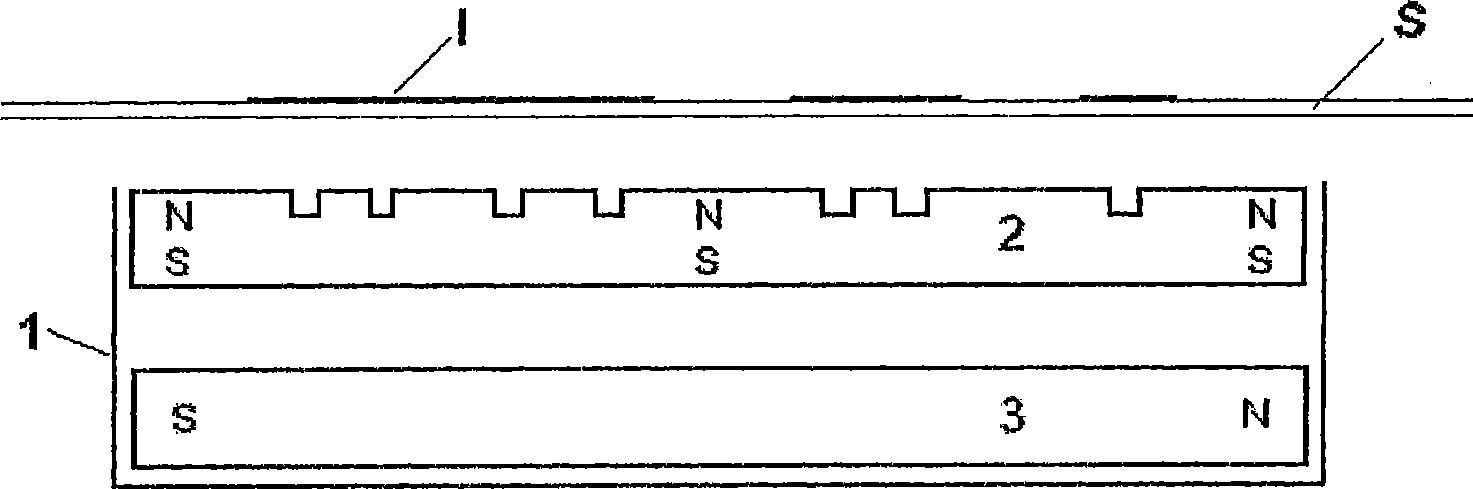

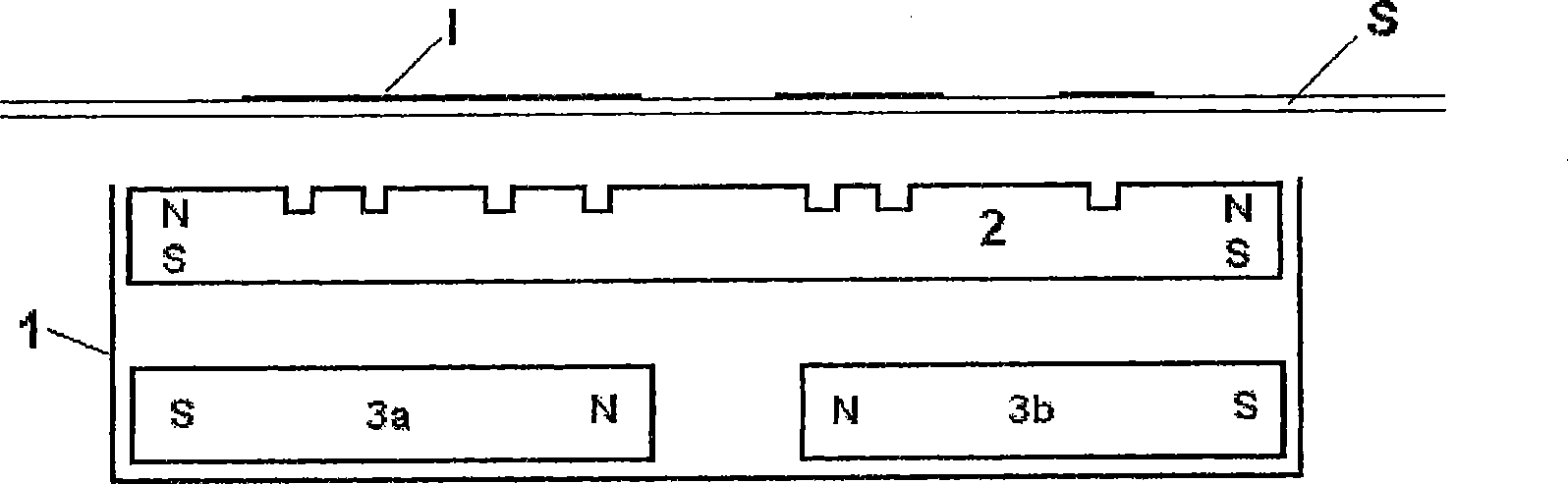

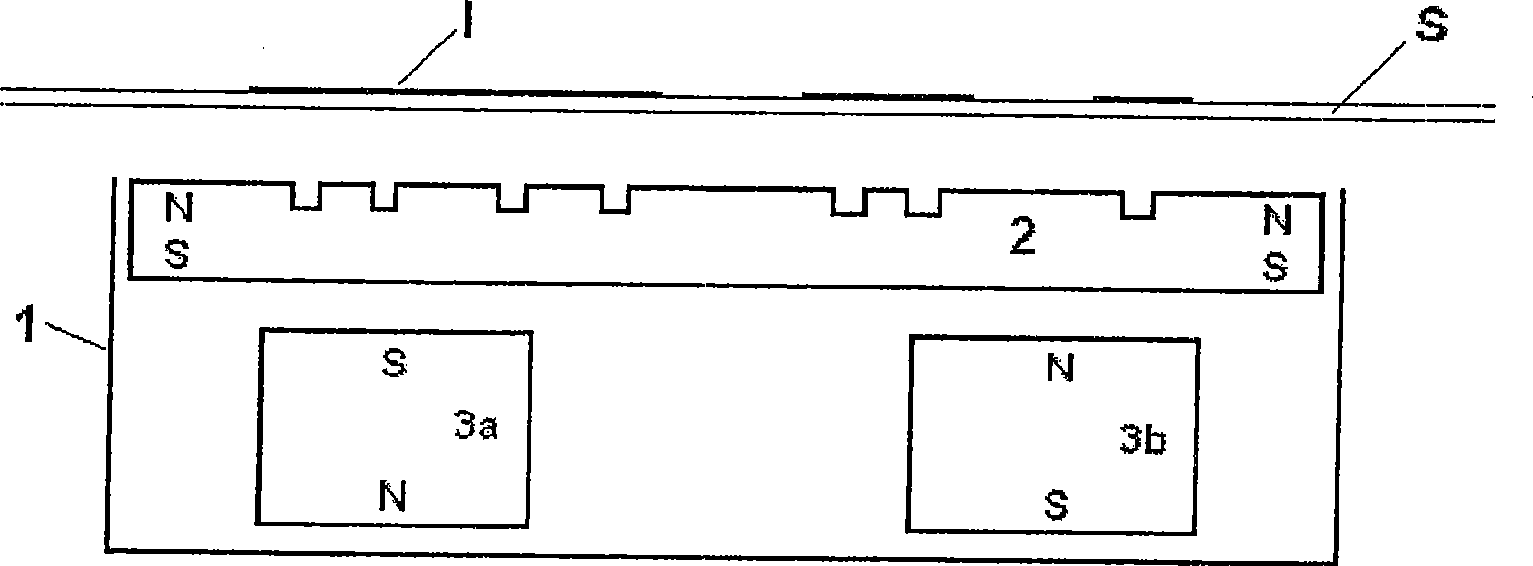

[0057] in accordance with Figure 7 , Figure 8 and specifically refer to Figure 9 In the exemplary embodiment shown, the scaffold (1) cut out of a block of aluminum is made to accommodate the SrFe 12 o 19 Two permanent magnet bars (3a, 3b) made of ceramic with dimensions 10×10×30 mm. These permanent magnets are secured and held in place by a press mechanism and screws. The poles of the two permanent magnets are Figure 7 Arrange as shown, or follow the Figure 8 Arrange as shown. An embossed permanent magnet plate (2) made of "plastic magnetic ferrite" with a size of 40 x 30 x 3 mm is arranged and fixed in place on the upper part of the permanent magnet bar so that said embossment remains accessible (i.e. seen from above).

[0058] On plastic ferrite plates, either with a mechanical engraving tool, or preferably with an automatic CO 2 Laser engraving tool or YAG laser engraving tool to engrave the desired high-resolution pattern.

[0059] The frame (1) is shaped to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com