Rotor assembly for use in line start permanent magnet synchronous motor

A technology of components and rotors, applied in the direction of electric components, asynchronous induction motors, synchronous machines, etc., can solve the problems of reducing efficiency, torque ripple, noise, etc., and achieve the effect of reducing torque ripple phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement the present invention. However, it should be appreciated that the present invention is not limited to the preferred embodiments, and may be varied in various ways.

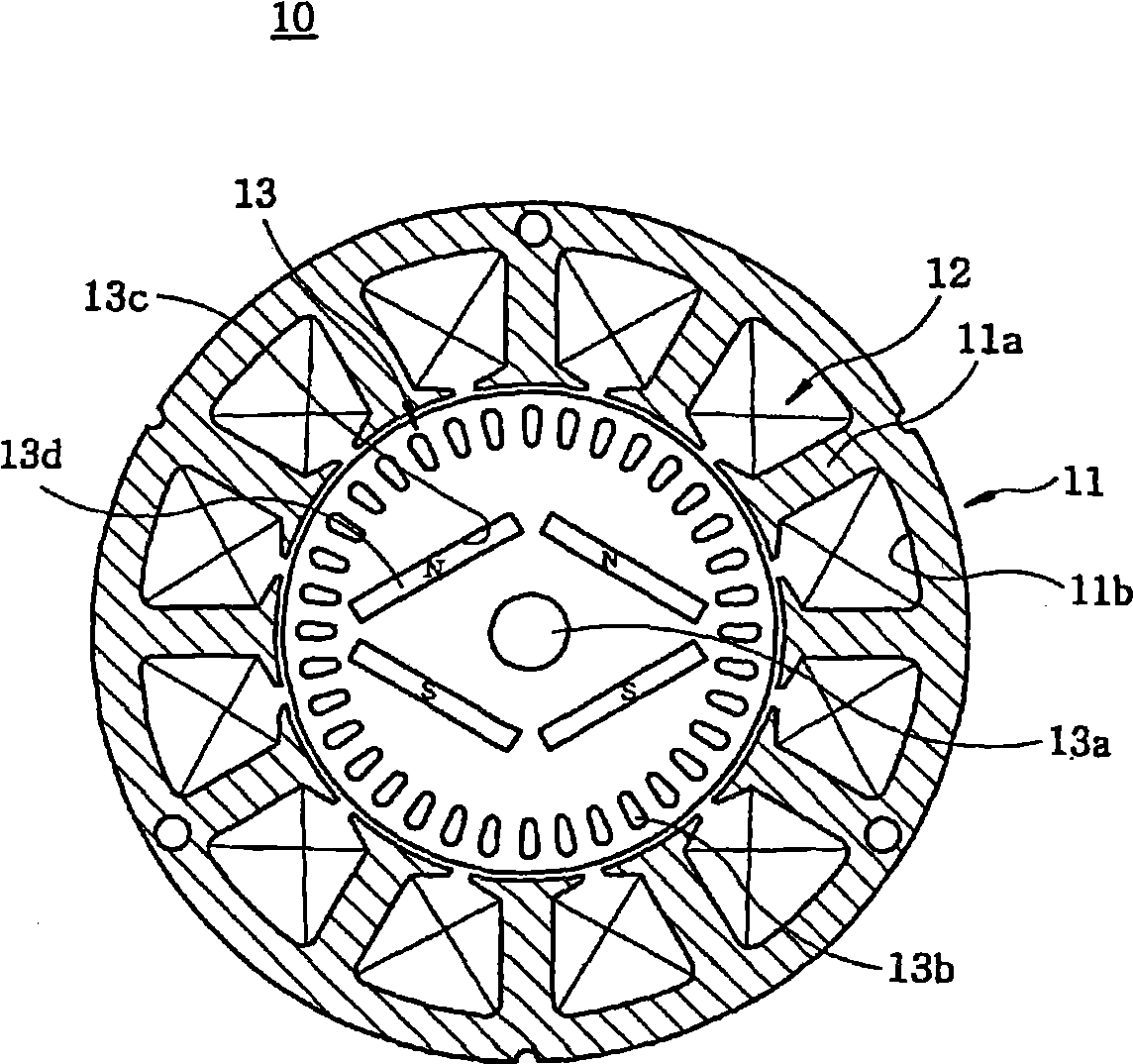

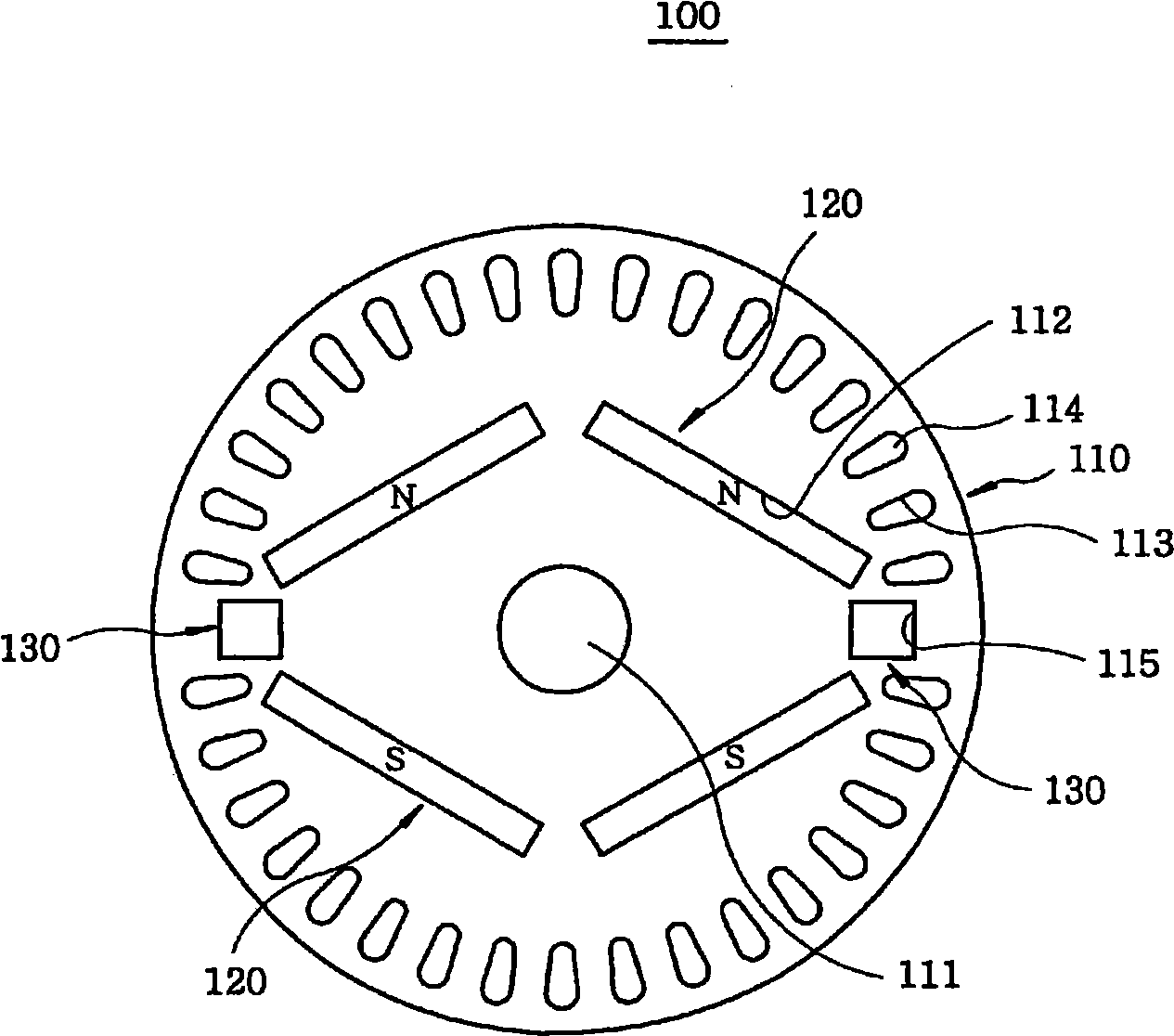

[0028] refer to image 3 , provides a plan view showing a rotor for a line-start permanent magnet (LSPM) synchronous motor according to a first embodiment of the present invention. Such as image 3 As shown, the rotor assembly 100 used in the LSPM synchronous motor according to the first embodiment of the present invention is installed inside the stator 11 (see figure 1 ), a gap is configured between the rotor assembly 100 and the stator 11 so that the rotor assembly 100 can rotate in the stator 11.

[0029] The rotor assembly 100 includes a rotor core 110, a plurality of permanent magnets 120 and a pair of pulsation supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com