Environmental protection type nonwoven needle punched carpet and manufacturing method thereof

A technology of non-woven needle punching and manufacturing methods, which is applied to carpets, textiles, papermaking, non-woven fabrics, etc., and can solve the problems that non-woven needle punched carpets cannot be recycled and reproduced, the cost of site use is increased, and it is not in line with economic benefits. Save working space, reduce energy consumption, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

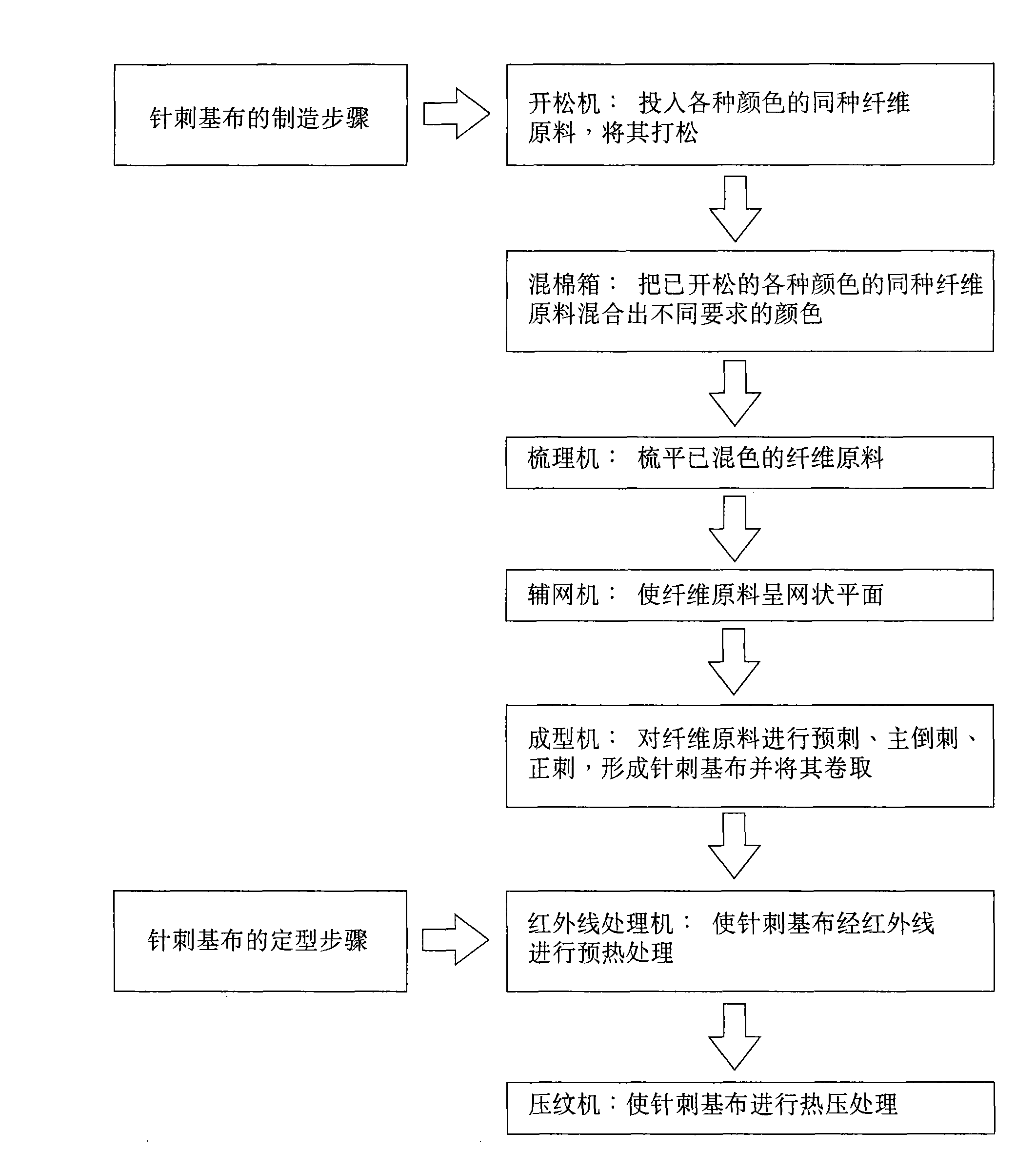

[0027] refer to figure 1 According to the manufacturing method of the environment-friendly non-woven needle-punched carpet of the present invention, at first the same kind of fiber raw materials of various colors are put into the opener, and it is loosened; then the same kind of fiber raw materials of various colors that have been opened are Put it into the cotton mixing box to mix different required colors; then use the carding machine to comb the mixed fiber raw materials; then enter the auxiliary net machine to make the fiber raw materials form a mesh plane; then pre-puncture the fiber raw materials by the forming machine The main barbs and frontal thorns form the needle-punched base fabric and roll it up. The above steps complete the manufacture of the non-woven needle-punched base fabric. Next, enter the shaping step of the needle-punched base fabric, that is, make the non-woven needle-punched base fabric undergo infrared preheating treatment through an infrared processo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com