Equipment for region-type raceway conveying

A technology for conveying equipment and raceways, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc. It can solve the problems of damage to the contact surface between workpieces and rollers, and can not be guaranteed, so as to achieve reasonable conveying methods, eliminate relative sliding, and run stably reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

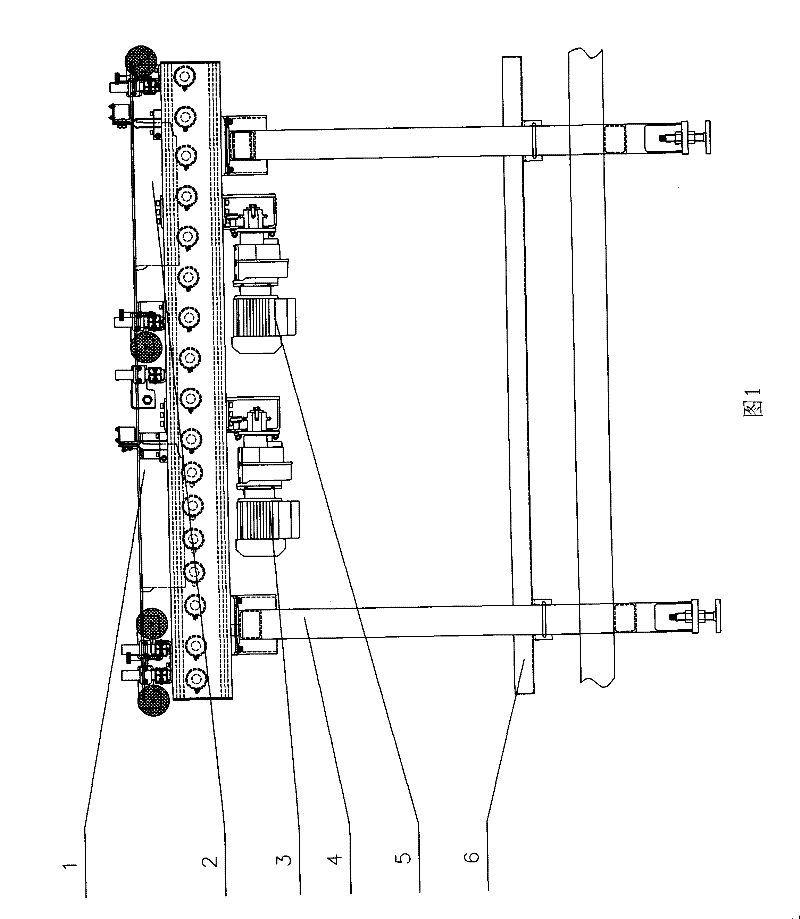

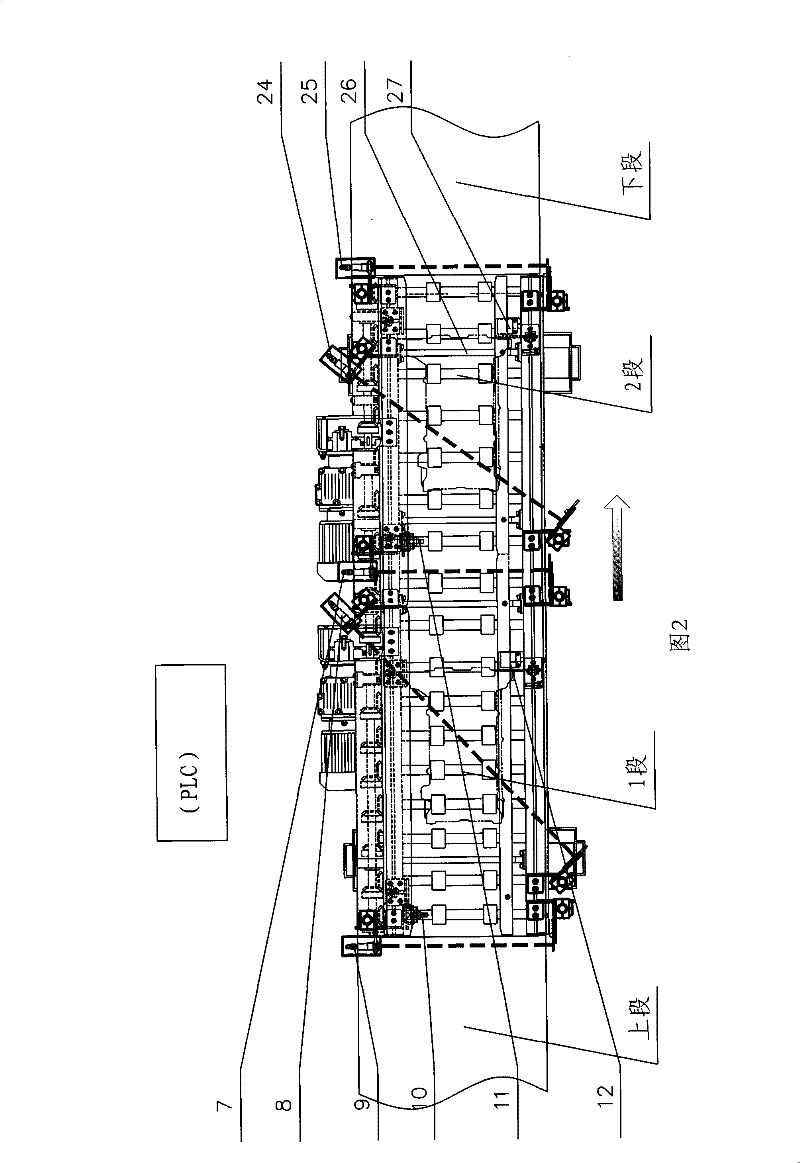

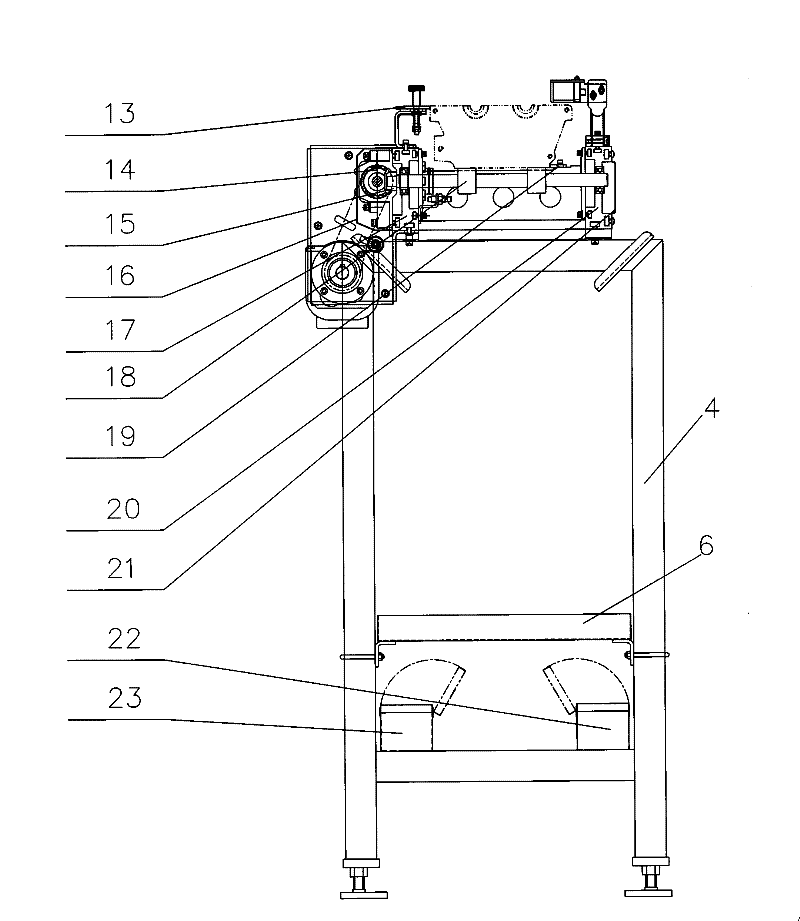

[0021] like figure 1 , 2 , the regional type raceway conveying equipment shown in 3, the regional type raceway conveying device of the present invention, the aluminum alloy wall panels 17, 20 are installed on the bracket 4, and the aluminum alloy wall panels on the bracket are installed under the steel plate welding with the open water ball valve Rectangular box body type water receiving tray 6, electrical wiring trough 22 and pneumatic wiring trough 23 are installed on the bracket below the water receiving tray 6, roller shaft 18, bevel gear pair 14, 15, power assembly 3, 5, guide device, The photoelectric switch etc. are installed on the aluminum alloy wallboard; the roller shaft 18 is heat-fitted on the shaft for integral processing to ensure coaxiality, the surface of the roller is quenched, and the surface of the roller shaft is chemically plated to ensure wear resistance and corrosion resistance. Bevel gear pairs 14, 15 are made of high strength and high wear resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com