Method for producing polyester

A production method and technology of polyester, applied in the field of polyester production, can solve the problems of high production cost, high energy consumption, large water ratio, etc., and achieve good color tone and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] With the device of the comparative example, ethylene glycol is replaced by biological source ethylene glycol, and the addition amount of other raw materials and catalysts remains unchanged, and the esterification and polycondensation reactions are completed in the same temperature range to obtain the poly(p-phenylene) of the present invention. Ethylene glycol diformate products. The amount added relative to the polyester weight is:

[0031] The addition amount of titanium element in titanium compound is 5ppm

[0032] The amount of phosphorus added in the phosphorus compound is 13ppm

[0033] The addition amount of magnesium element in the magnesium compound is 40ppm.

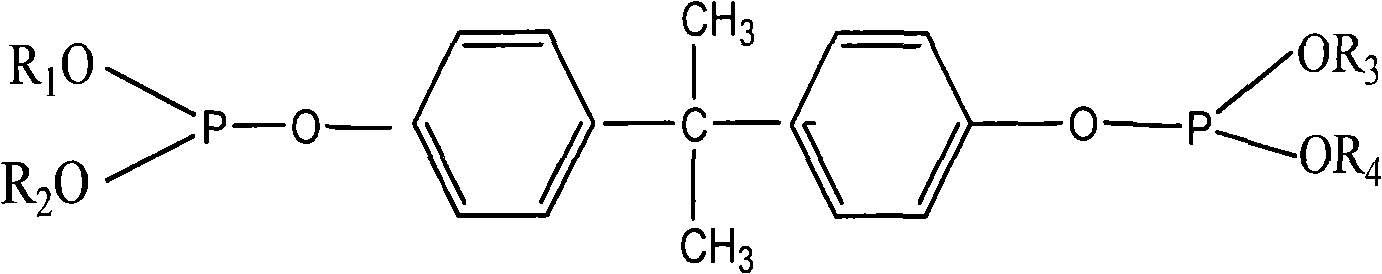

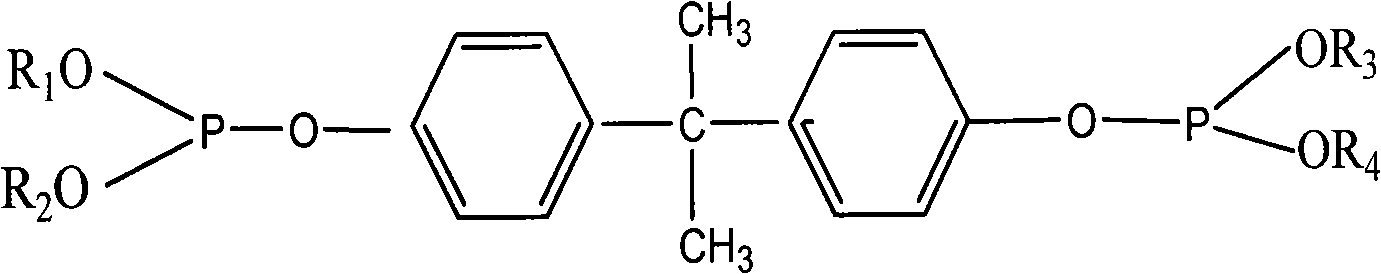

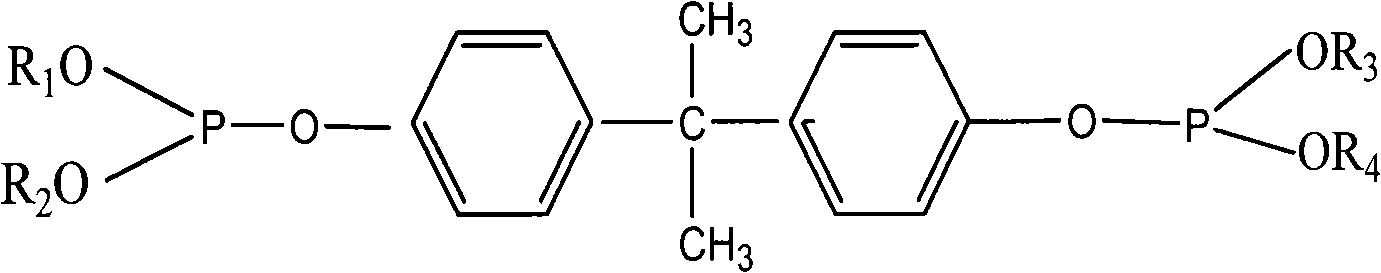

[0034] Phosphorous compounds are phosphites and have the following structure,

[0035]

[0036] where R 1 , R 2 , R 3 , R 4 is an alkyl, cycloalkyl, arylalkyl or alkylaryl group with 4 to 25 carbons. Example R 1 , R 2 , R 3 , R 4 Can be 3-methyl-5-ethyloctane, 2,5-dimethyl-3,4-diethylhexane...

Embodiment 2

[0039] In the device of the comparative example, the ethylene glycol is replaced by bio-sourced ethylene glycol, the phosphorus compound is replaced by phosphoric acid, and the addition amount of other raw materials and catalysts remains unchanged. The esterification and polycondensation reactions are completed in the same temperature range, and the present Invention of polyethylene terephthalate articles. The amount added relative to the polyester weight is:

[0040] The addition amount of titanium element in titanium compound is 5ppm

[0041] The amount of phosphorus added in the phosphorus compound is 13ppm

[0042] The addition amount of magnesium element in the magnesium compound is 40ppm.

[0043] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com