Gasification furnace

A gasifier and furnace body technology, which is applied in the field of gasifiers and achieves the effects of high safety, reduced furnace cover materials and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

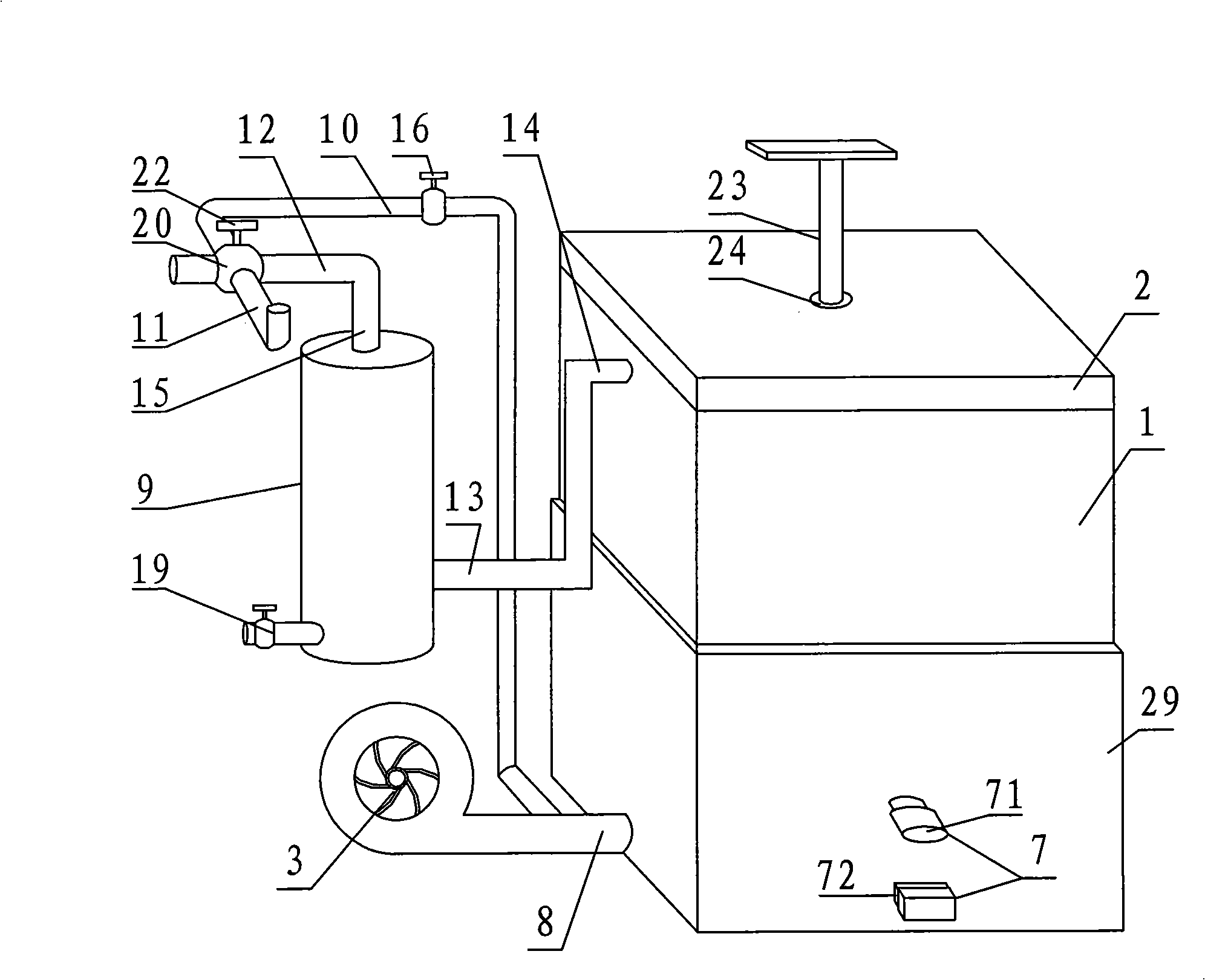

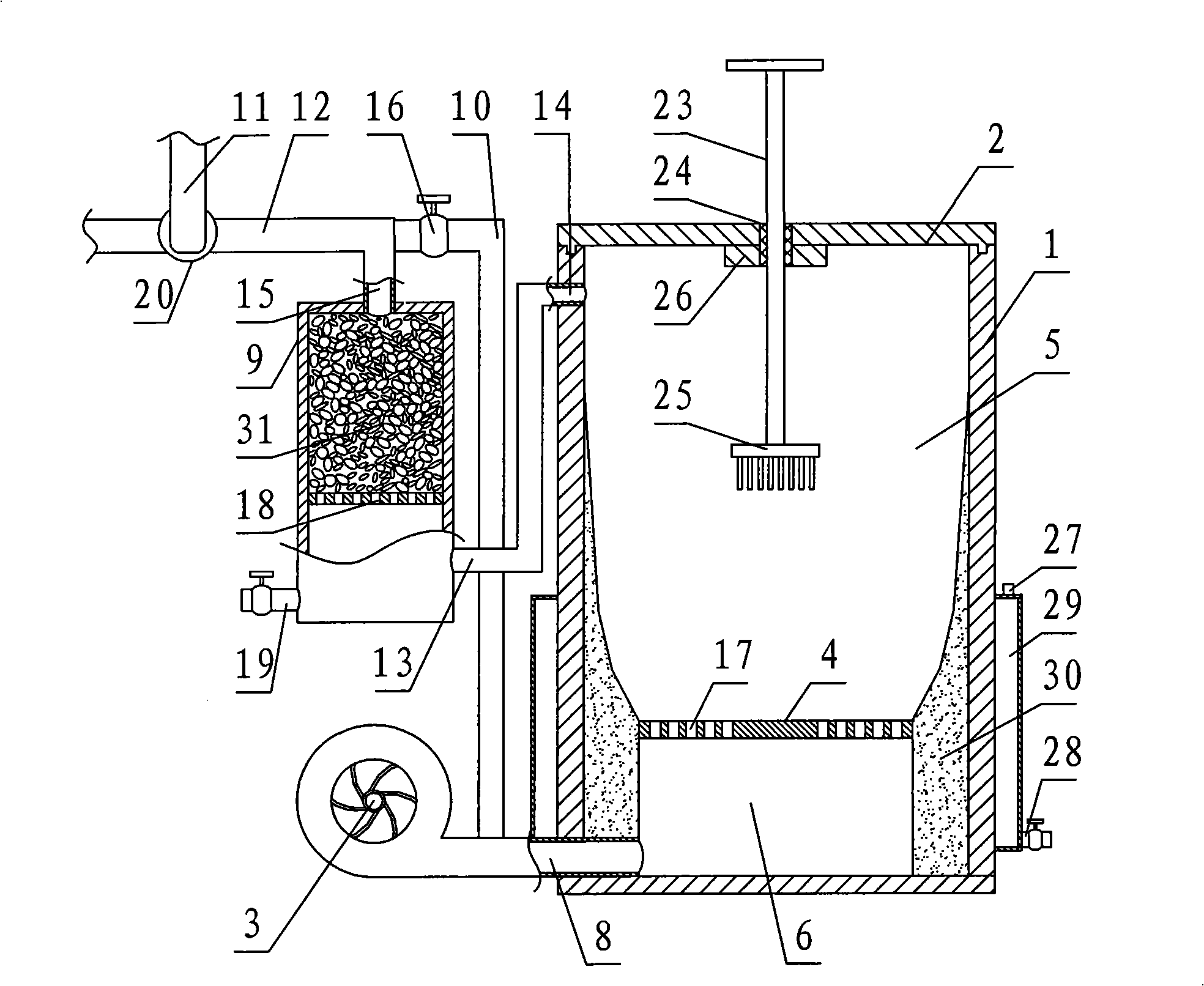

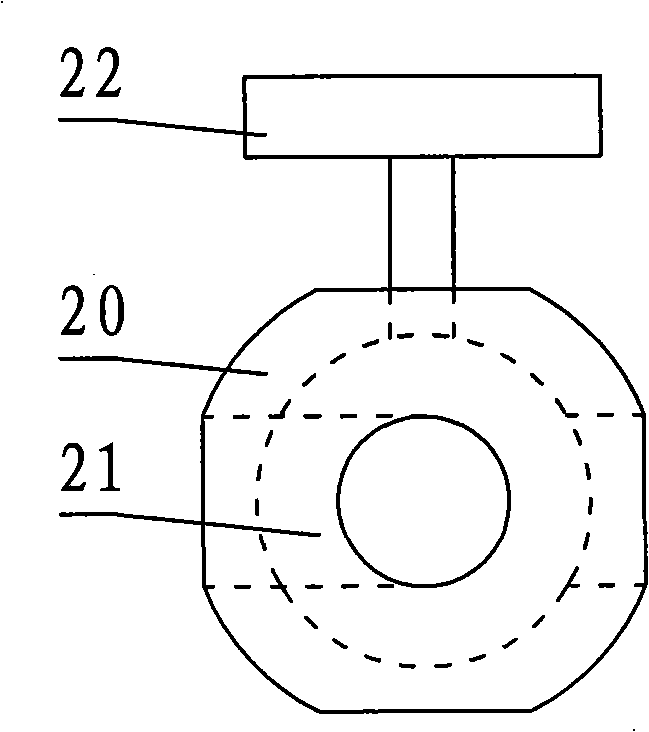

[0023] Such as figure 1 and figure 2 As shown, during specific implementation, the gasification furnace is composed of a furnace body 1, a furnace cover 2 that is watertightly matched with the groove of the furnace body 1, a blower 3, and a gas delivery system, and a partition plate is arranged inside the furnace body 1 4. Divide the inner cavity of the furnace body 1 into the upper gas chamber 5 and the lower ash chamber 6. The ash outlet 7 and the air inlet 8 are arranged under the furnace body 1. The air inlet 8 is located on the outer wall of the furnace ash chamber 6 and Link to each other with blower 3, described blower 3 adopts the blower that is provided with regulating switch, can adjust the blower of air volume size; Described air transmission system comprises purifier 9, secondary ventilation pipe 10, waste gas pipe 11 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com