Method for monitoring and controlling hydrogen sulfide in sulfur-containing stratum underbalanced drilling

A technology of underbalanced drilling and control method, applied in the directions of surveying, earthwork drilling, flushing wellbore, etc., can solve problems such as safety accidents, hydrogen sulfide volatilization, atmospheric environment damage, etc., and achieve the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

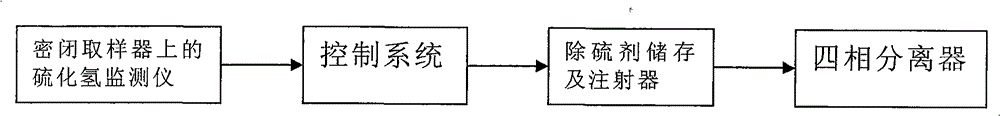

[0029] Refer to the attached figure 2 , the invention discloses a method for monitoring and controlling hydrogen sulfide in underbalanced drilling in sulfur-bearing formations. First, the drilling fluid containing hydrogen sulfide returned from the well is processed through a closed device, and the closed device at least includes a closed sampler, four Phase separator, closed grit chamber, closed oil storage tank, closed drilling fluid buffer tank and vacuum degasser, the treated drilling fluid is discharged into the solids control system, and after the performance of the drilling fluid is adjusted, it is circulated to In the well, when the drilling fluid passes through the closed sampler, the hydrogen sulfide content in the drilling fluid is monitored, and the monitored hydrogen sulfide content signal is input to the control system. The sulfur agent goes to the four-phase separator and reacts the hydrogen sulfide in the drilling fluid with the sulfur removal agent to remove ...

Embodiment 2

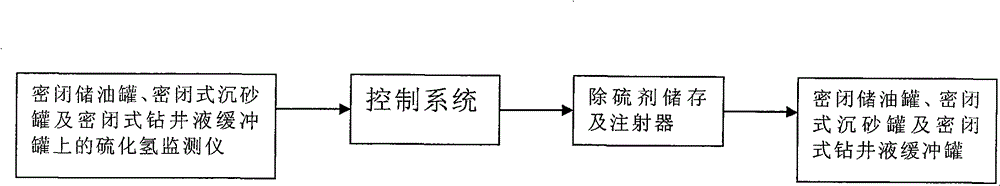

[0031] Refer to the attached figure 1 , 2 , a preferred embodiment of the present invention is: on the basis of embodiment 1, when the drilling fluid passes through the closed grit chamber, the closed oil storage tank and the closed drilling fluid buffer tank, the content of hydrogen sulfide in the drilling fluid is monitored respectively, And input the monitored hydrogen sulfide content signals to the control system, the control system respectively converts the amount of corresponding desulfurization agent required and issues instructions, injects desulfurization agent and makes the closed grit chamber, closed oil storage tank and The hydrogen sulfide in the closed drilling fluid buffer tank reacts with the respective injected desulfurizers to further remove residual hydrogen sulfide.

Embodiment 3

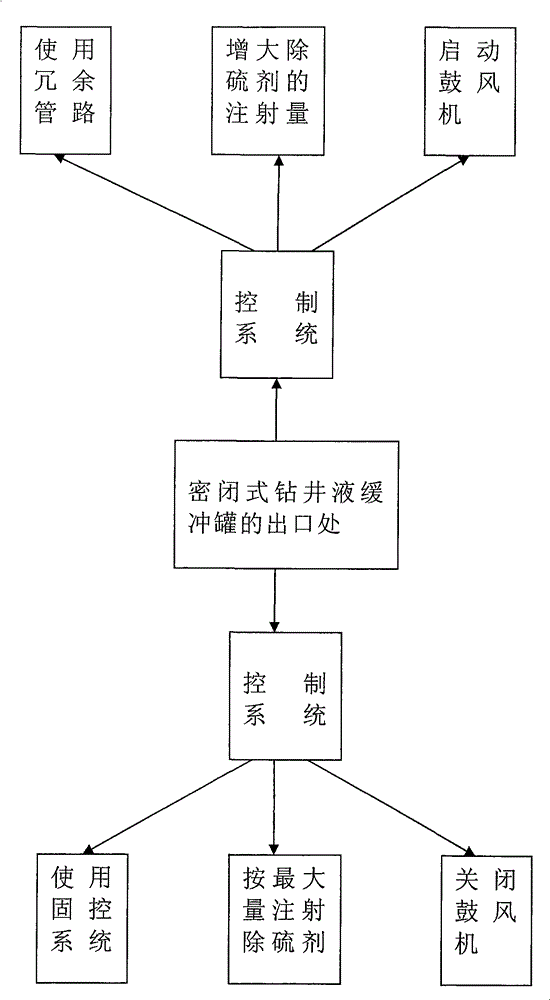

[0033] Refer to the attached figure 1 , 2 , 3, another preferred embodiment of the present invention is: on the basis of embodiment 1 or 2, also carry out the monitoring of hydrogen sulfide content to the drilling fluid that flows out by closed drilling fluid buffer tank, when hydrogen sulfide is still not completely removed , or the hydrogen sulfide content in the drilling fluid returned from the well suddenly rises, but the sealing device cannot be completely removed, the detected hydrogen sulfide content signal is input to the control system, and the control system issues an instruction: close the closed drilling fluid buffer tank and solid control The valve on the system, and open the valve between the closed drilling fluid buffer tank and the drilling pump, so that the drilling fluid is directly pumped into the standpipe by the drilling pump; when the hydrogen sulfide content of the drilling fluid flowing out of the closed drilling fluid buffer tank is monitored When it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com