Ore-slurry multi-potential detector

A detection device and ore pulp technology, applied in the direction of measurement device, measurement of electrical variables, measurement of current/voltage, etc., can solve the problems of long balance time of detection electrodes, complicated structure and operation, poor adaptability of online detection, etc., so as to alleviate safety and balance Difficulty, overcoming the complex structure and operation, and the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

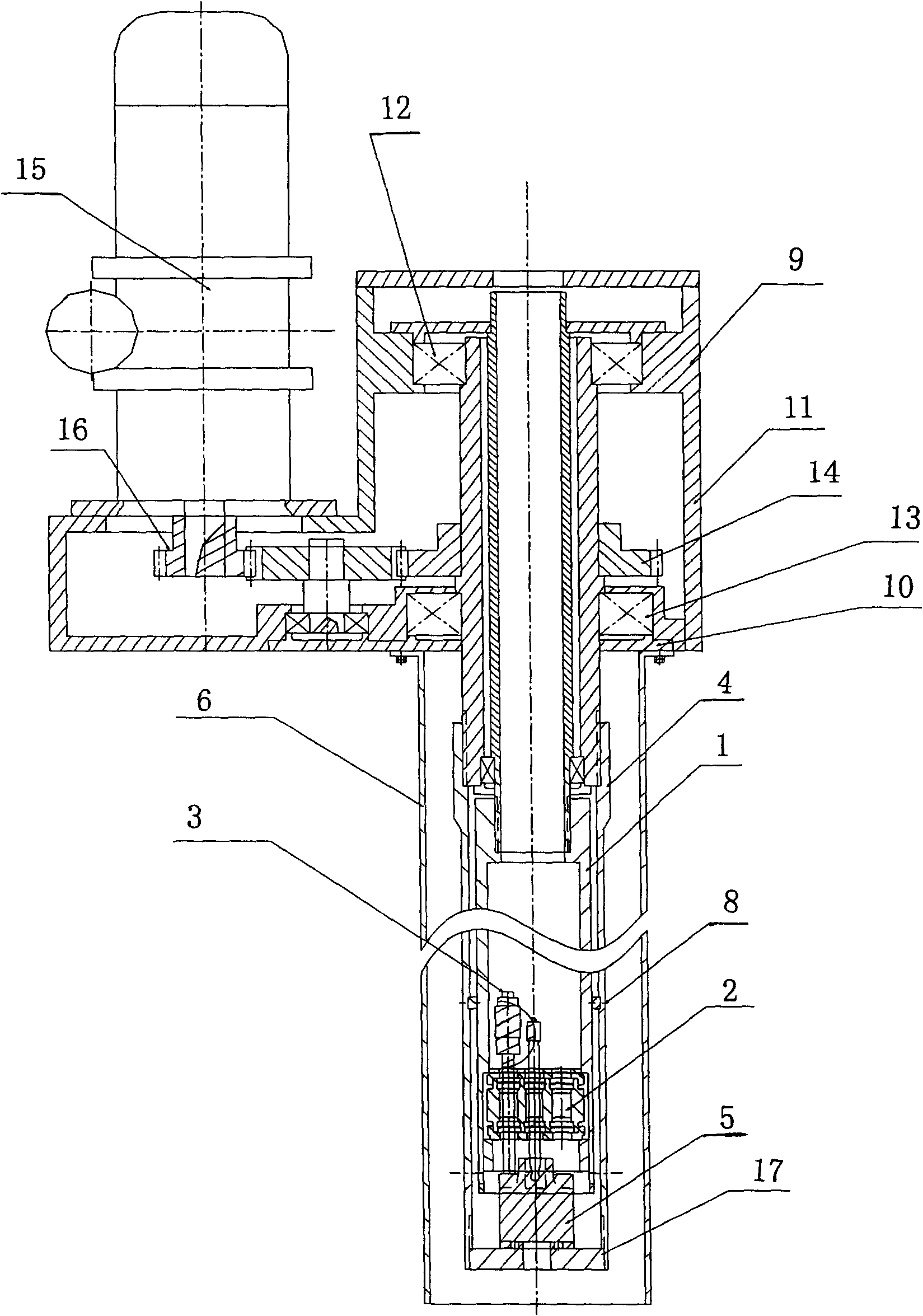

[0044] Put a domestic pH302-2 spherical glass pH electrode and a silver / silver chloride electrode into the electrode holder respectively, and then tighten the sensitive surface of the electrode stick Vertical blade positioning. At this point, put the main unit in the pulp to be measured, and then connect the electrode guide wire to the meter to realize the online electrode potential detection under the recovery state of the electrode.

Embodiment 2

[0046] Put a domestic pH302-2 spherical glass pH electrode, a silver / sulfur ion selective electrode, a flat platinum electrode, and a silver / silver chloride electrode into the electrode holder, and the sensitive surface of the electrode is tightly connected to the notch of the scraper. stick Positioning, place the host in the pulp to be tested. Finally, the electrode guide wire is connected with the instrument, that is, the synchronous and real-time detection of the online multi-electrode potential under the electrode recovery operation state is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com