Method for rapidly determining content of preservatives in condiment

A determination method and rapid determination technology, which can be used in measurement devices, instruments, scientific instruments, etc., can solve the problems of macromolecular interference, low extraction rate, long pretreatment time, etc., and achieve accurate results and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Accurately weigh 1.000g each of light soy sauce sample, dark soy sauce sample, mature vinegar sample, rice vinegar sample, and seasoning sauce sample, and place them in 15ml centrifuge tubes;

[0055] 2) Add 5 drops of hydrochloric acid, 0.50 ml of internal standard solution, and 5 ml of extractant 5 to each centrifuge tube in turn, shake well, and draw each supernatant for sampling;

[0056] 3) According to the aforementioned instrument conditions, the temperature of the column oven of the instrument was raised to the initial temperature of 100° C., and after the instrument stabilized, each supernatant was injected and analyzed respectively. The temperature of the instrument is programmed, that is, the initial temperature is 100°C, kept for 0.5min, raised to 220°C at 20°C / min, then raised to 250°C at 60°C / min, kept for 1min, and operated for a total of 8.0min.

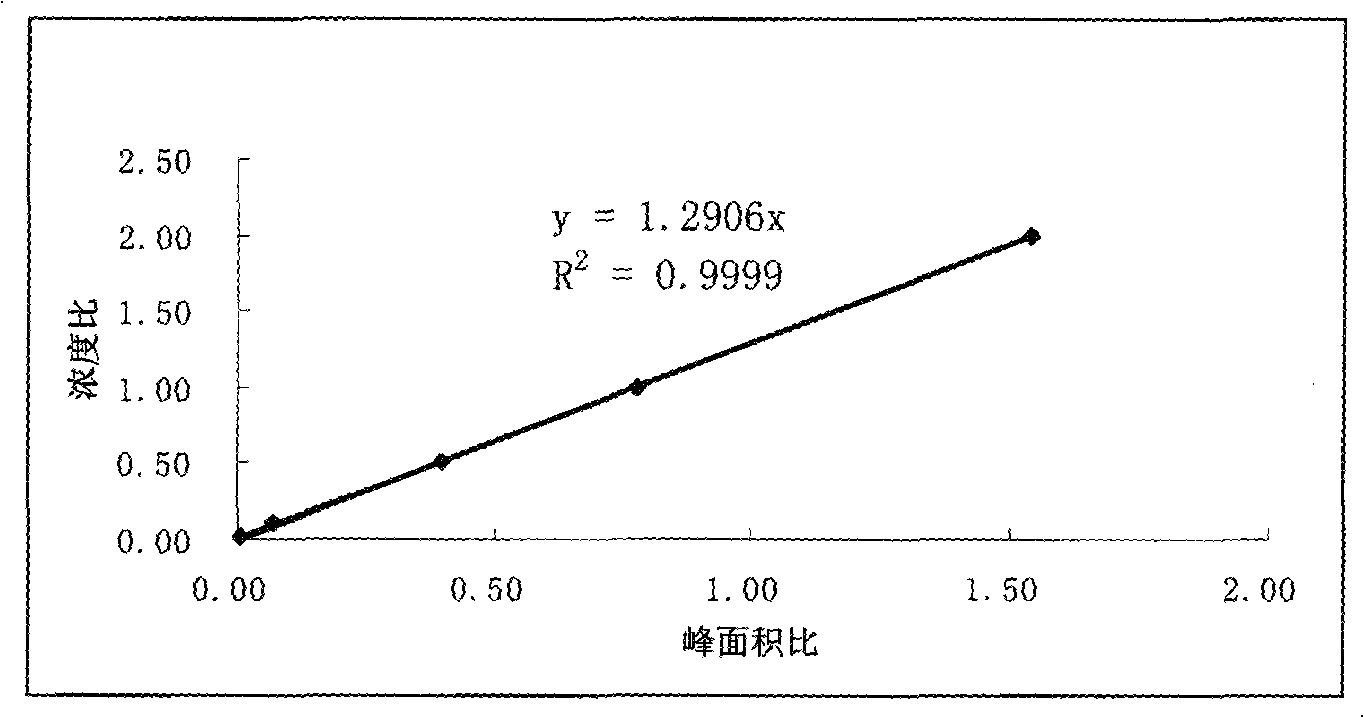

[0057] 4) the ratio of the obtained component peak area to each internal standard peak area and figure 1...

Embodiment 2

[0064] 1) Accurately weigh 1.000g of oyster sauce, put it in a 15ml centrifuge tube, add 0.1ml of amylase, and shake for a while;

[0065] 2) After the sample becomes thinner, add 5 drops of hydrochloric acid, 0.50ml of internal standard solution, and 5.00ml of extractant 1 in sequence, shake well, centrifuge, absorb the supernatant and inject the sample.

[0066] 3) According to the aforementioned instrument conditions, the temperature of the column oven of the instrument was raised to the initial temperature of 110°C, and after the instrument was stabilized, the supernatant was injected for analysis. The temperature of the instrument is programmed, that is, the starting temperature is 110°C, keep for 1min, rise to 180°C at 15°C / min, then rise to 280°C at 50°C / min, keep for 1min, and run for a total of 8.67min.

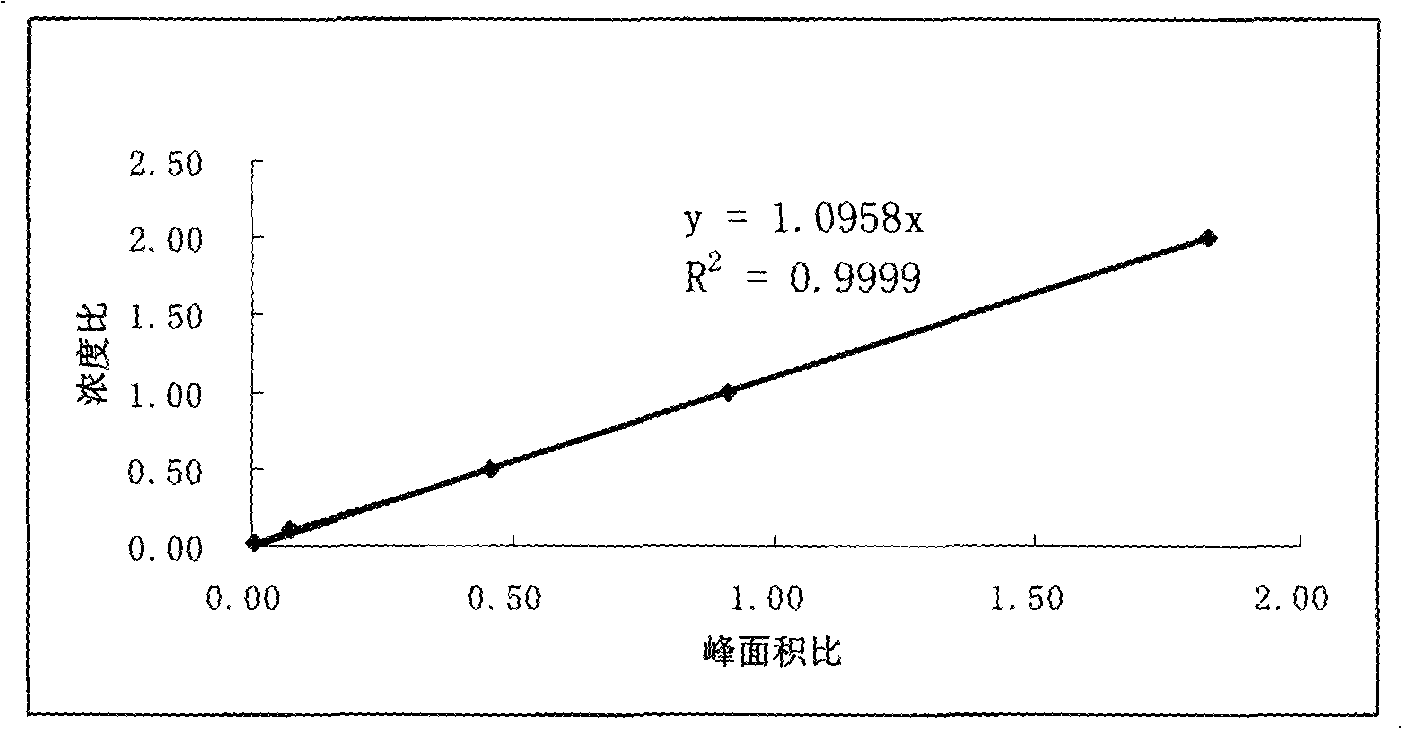

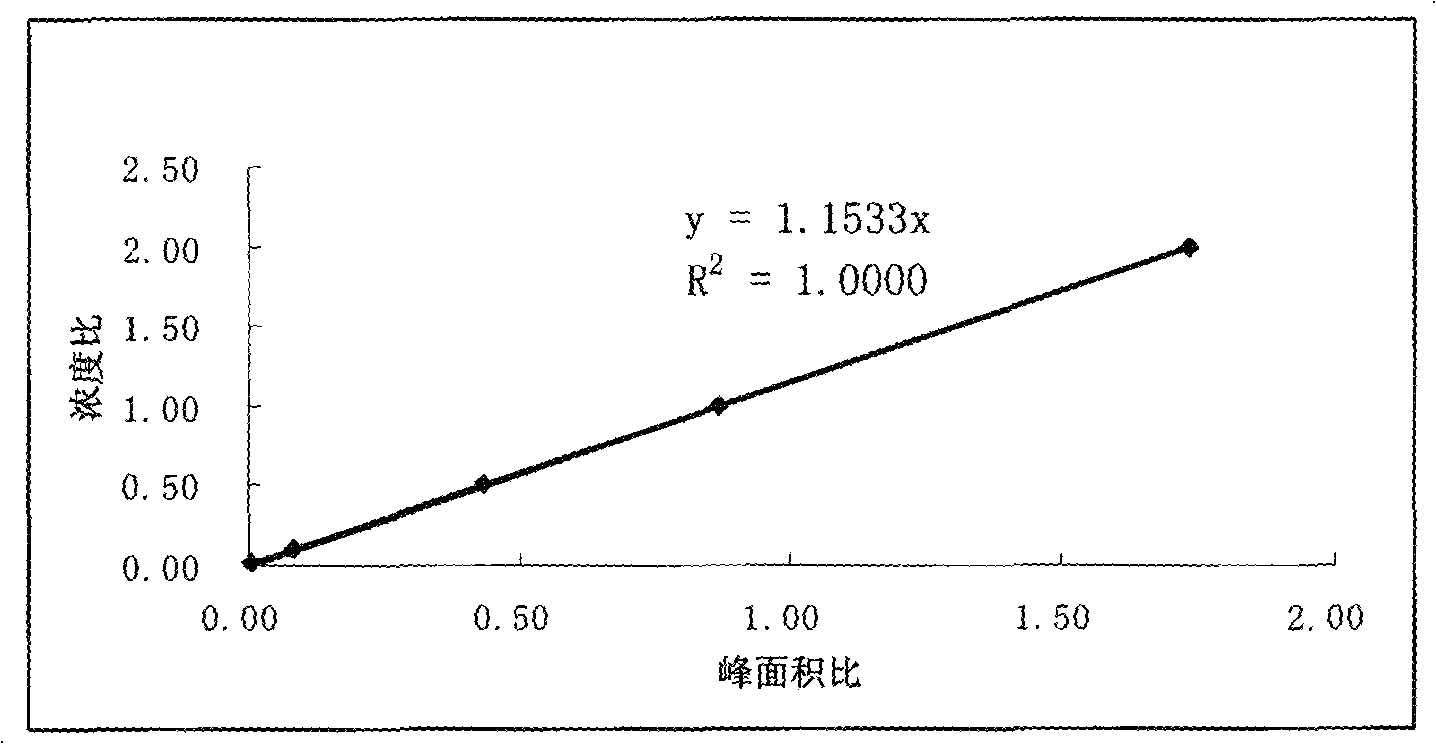

[0067] 4) The ratio of the obtained component peak area to the internal standard peak area and figure 1 , figure 2 , image 3 Comparing the standard curves of oy...

Embodiment 3

[0069] 1) Accurately weigh 1.000g of oil-free sauce, put it in a 15ml centrifuge tube, add 0.5ml of distilled water, and shake for a while;

[0070] 2) Add 5 drops of hydrochloric acid, 0.50 ml of internal standard solution, and 5 ml of extractant 7 in sequence, shake well, centrifuge, absorb the supernatant and inject the sample.

[0071] 3) According to the aforementioned instrument conditions, the temperature of the column oven of the instrument was raised to the initial temperature of 90°C, and after the instrument stabilized, the supernatant was injected for analysis. The temperature of the instrument is programmed, that is, the starting temperature is 90°C, keep for 1min, rise to 220°C at 25°C / min, then rise to 300°C at 40°C / min, keep for 1min, and run for a total of 9.2min.

[0072] 4) The ratio of the obtained component peak area to the internal standard peak area and figure 1 , figure 2 , image 3 Compared with the standard curve, the content of sorbic acid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com