Method for processing watermelon water and watermelon juice by combining ultrasonic and ultrahigh pressure

An ultra-high pressure, melon juice technology, applied in food science and other directions, can solve the problems of loss of nutrients, reduced product quality, and no preparation process for melon water and melon juice, and achieves a simple and easy production process. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

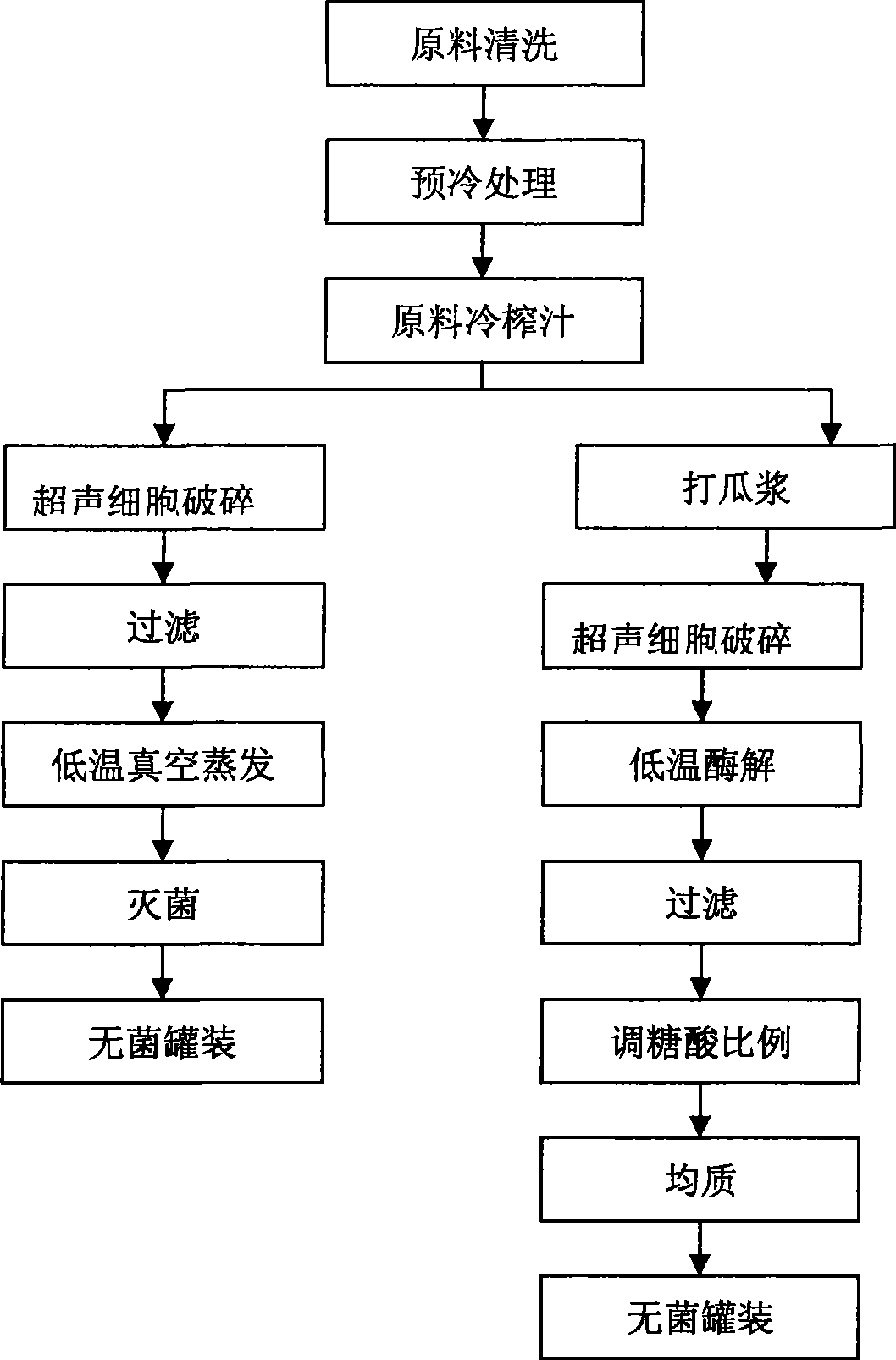

Image

Examples

example 1

[0034] Example 1: Melon water

[0035] Choose fresh melon raw materials; remove impurities and clean them, pre-cool at 8-12°C for 1 hour, then peel and remove the pulp and add 0.05% Vc and 0.05% citric acid for cold-pressing; ultrasonic cell crushing, ultrasonic power 200W, Ultrasonic time is 5 minutes; the pumpkin juice obtained after filtration is subjected to low-temperature vacuum evaporation extraction, the evaporation temperature is 60°C, and the time is 15 minutes; ultra-high pressure and ultraviolet light cold sterilization technology is used for sterilization and enzyme treatment, the pressure used is 350MPa, and the time is 10 minutes; Radiation intensity 45mW / cm 2 , time 5s; then carry out aseptic canning. The product has the natural characteristic aroma of pumpkin, clear and transparent.

example 2

[0036] Example 2: Melon water

[0037] Choose fresh melon raw materials; remove impurities and clean them, pre-cool at 8-12°C for 1 hour, then peel and remove the pulp, add 0.05% Vc and 0.05% citric acid for cold pressing; ultrasonic cell crushing, ultrasonic power 100W, Ultrasonic time is 8 minutes; the pumpkin juice obtained after filtration is subjected to low-temperature vacuum evaporation extraction, the evaporation temperature is 55°C, and the time is 15 minutes; ultra-high pressure and ultraviolet light cold sterilization technology is used for sterilization and enzymatic treatment, the pressure used is 300MPa, and the time is 10 minutes; Radiation intensity 45mW / cm 2 , time 10s; then aseptic canning. The product has the natural characteristic aroma of pumpkin, clear and transparent.

example 3

[0038] Example 3: Melon water

[0039] Choose fresh melon raw materials; remove impurities and clean them, pre-cool at 8-12°C for 1 hour, then peel and remove the pulp and add 0.05% Vc and 0.05% citric acid for cold-pressing; ultrasonic cell crushing, ultrasonic power 200W, Ultrasonic time is 5 minutes; the pumpkin juice obtained after filtration is subjected to low-temperature vacuum evaporation extraction, the evaporation temperature is 60°C, and the time is 15 minutes; ultra-high pressure and ultraviolet light cold sterilization technology is used for sterilization and enzyme treatment, the pressure used is 300 MPa, and the time is 5 minutes; Radiation intensity 60mW / cm 2 , time 5s; then carry out aseptic canning. The product has the natural characteristic aroma of pumpkin, clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com