Laser sintering machine based on nano hydroxyapatite and used for manufacturing absorptive artificial bone

A nano-hydroxyapatite, laser sintering technology, applied in manufacturing tools, laser welding equipment, metal processing equipment and other directions, to achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

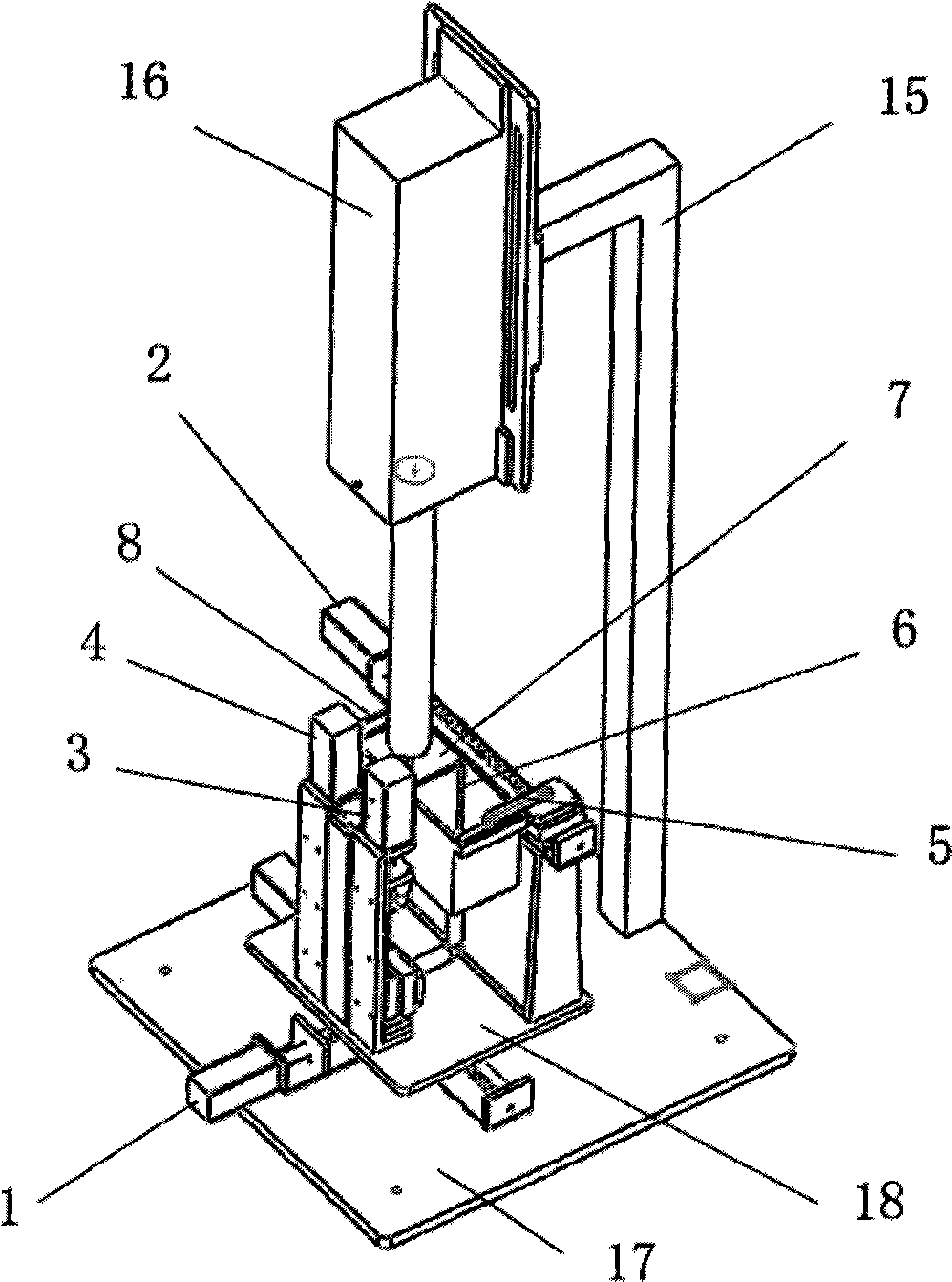

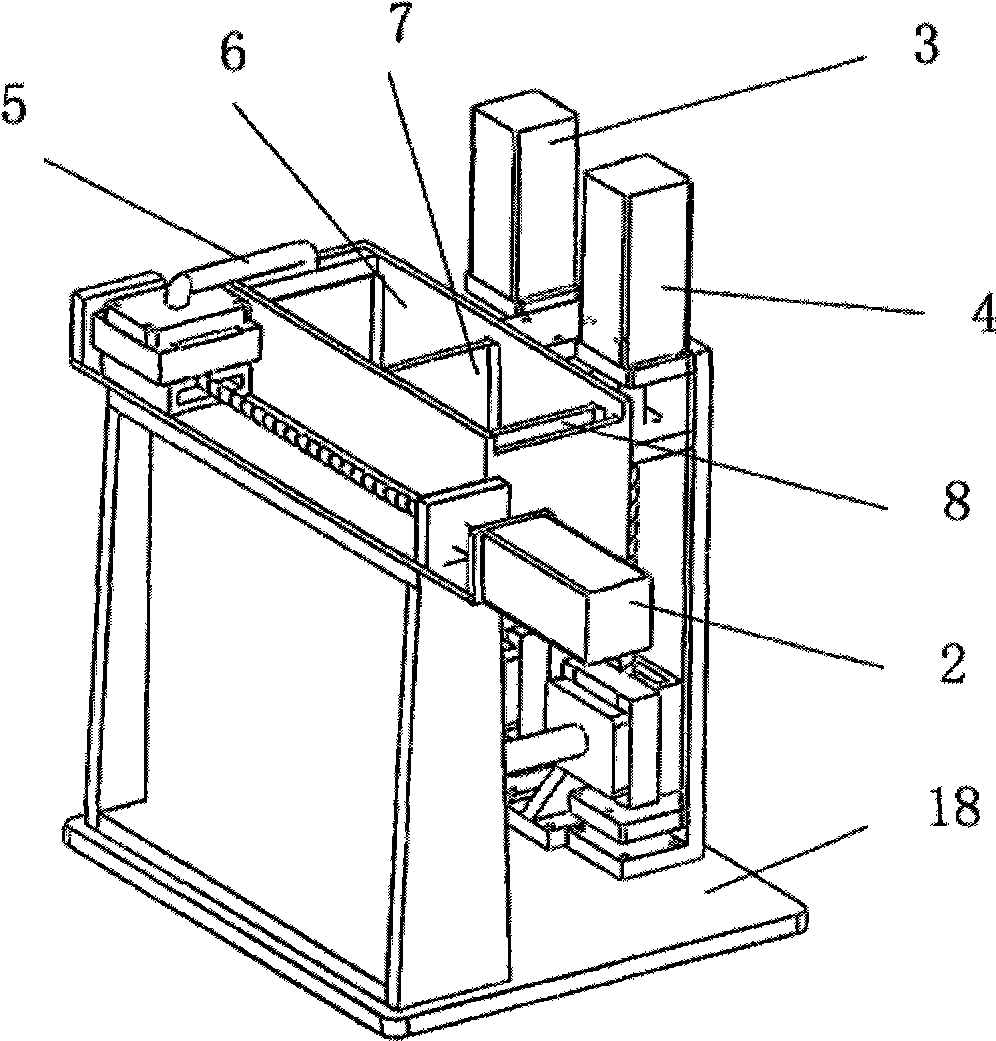

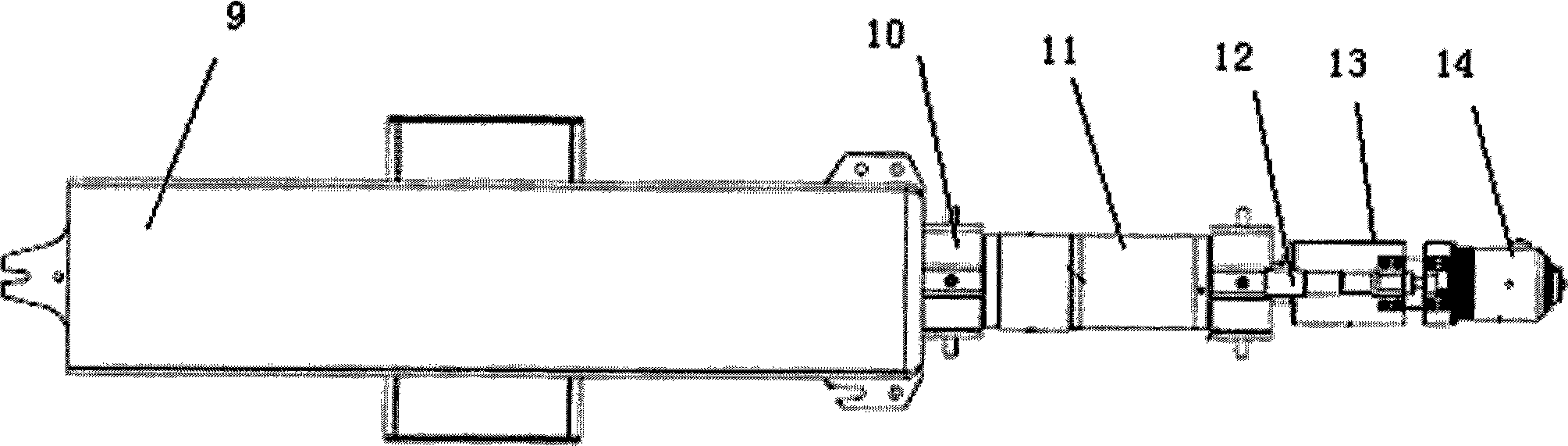

[0023] see figure 1 , figure 2 with image 3 , X, Y movement mechanism 1 is arranged on machine base 17, and sintering support plate 18 is arranged on X, Y movement mechanism 1, and raw material box up and down motion machine 3 and the raw material connected with it are arranged on sintering support plate 18. The box 6 and the sintering table up and down movement machine 4 and the sintering table 7 connected thereto, the sintering table up and down movement machine 4 is provided with a waste box 8 corresponding to the sintering table 7, and the sintering support plate 18 is provided with a feeding left and right movement mechanism 2. The feeding rod 5 corresponding to the raw material box 6 is installed on the feeding left and right movement mechanism 2, and a support 15 is provided on the machine base 17, and a laser and a laser focusing system corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com