Group management control device for elevator system

A control device, elevator system technology, applied in elevator energy efficiency, transportation and packaging, sustainable construction, etc., can solve problems such as increase in average waiting time, damage to user convenience, inability to start power-saving operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

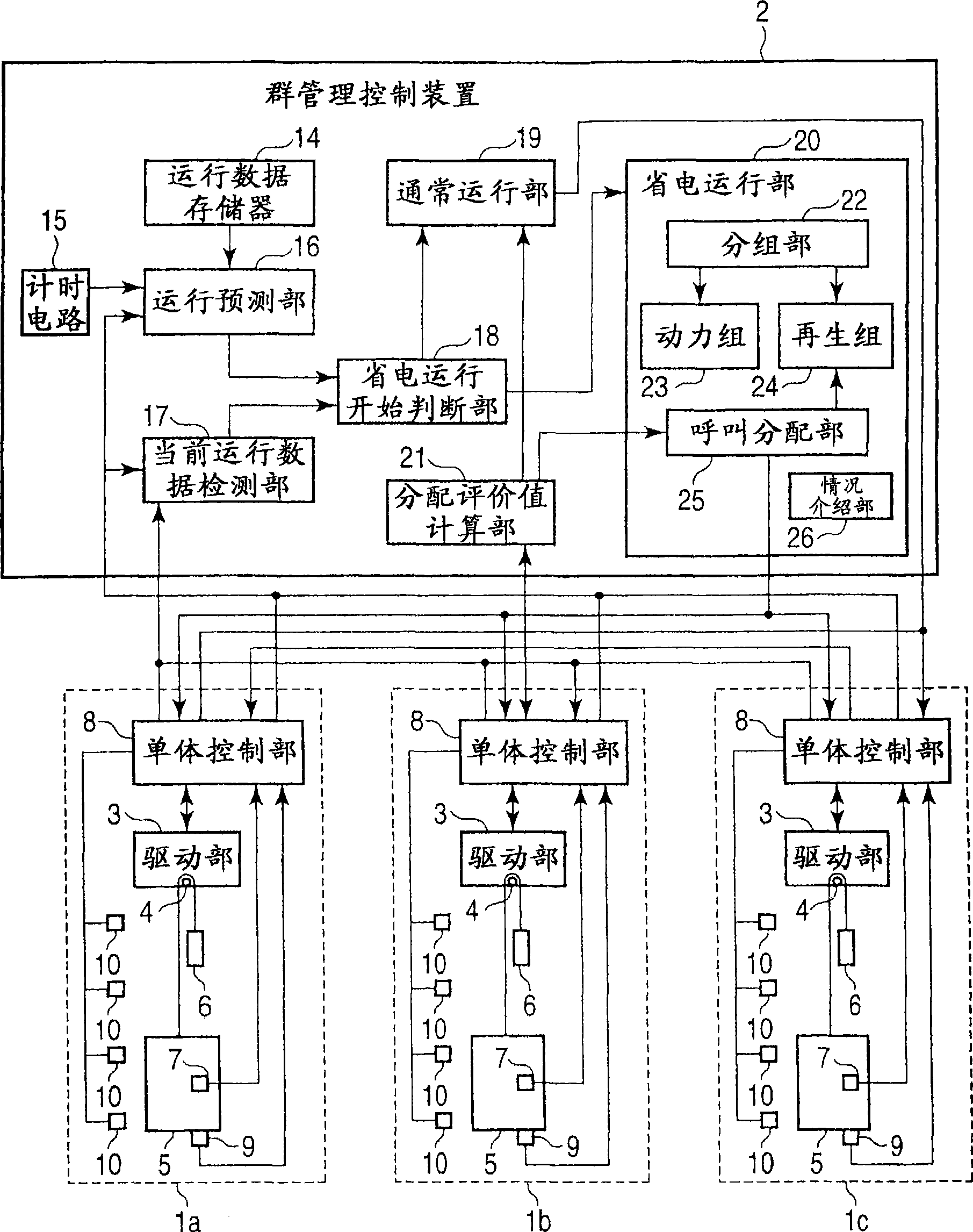

[0030] figure 1 It is a schematic configuration diagram showing an elevator system incorporating the group supervisory control device according to the first embodiment of the present invention.

[0031] The elevator system according to the first embodiment is mainly composed of a plurality of elevators 1a, 1b, and 1c and one group supervisory control device 2 . In each elevator 1a, 1b, 1c, the main wire rope is suspended on a reel connected to the shaft of the electric motor 4 assembled inside the driving part 3, which is installed in the lifting and lowering of the building not shown in the figure. the top of the pathway. A car 5 on which passengers ride is suspended from one end of the main cable, and a counterweight 6 is suspended from the other end of the main cable.

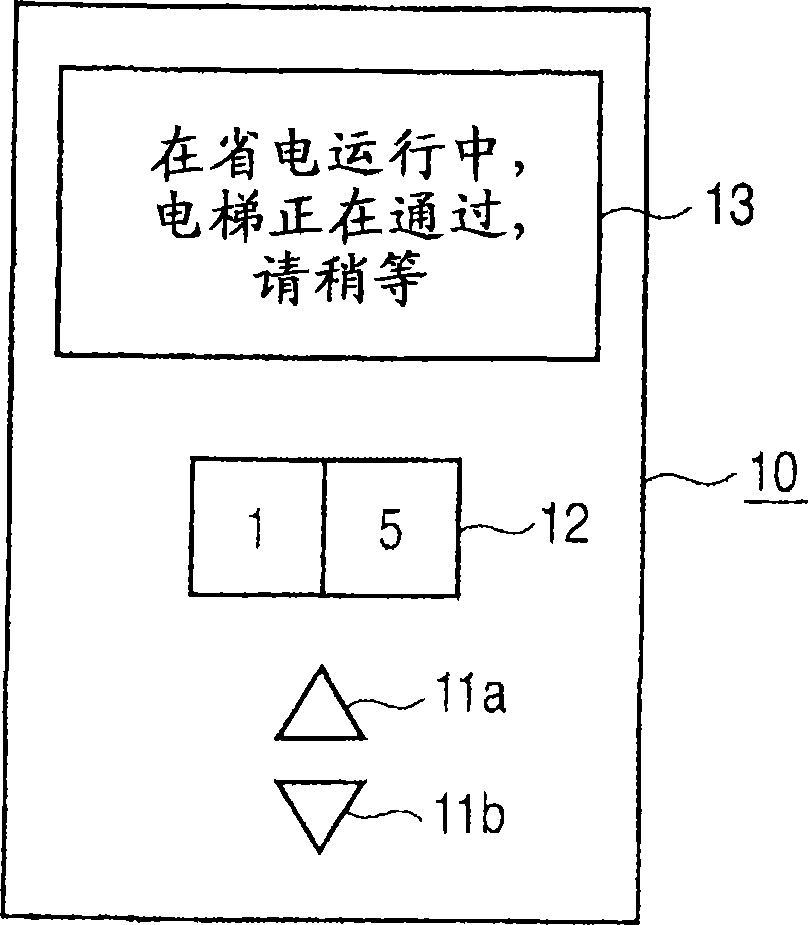

[0032] Inside the car 5, a car call registration device 7 for specifying a destination floor of the passenger riding on the car 5 is installed. The "car call" designating the destination floor specified b...

no. 2 Embodiment approach

[0070] Figure 7 It is a schematic configuration diagram of an elevator system incorporating a group supervisory control device according to a second embodiment of the present invention. for with figure 1 The same parts of the elevator system according to the first embodiment shown are denoted by the same reference numerals, and detailed description of overlapping parts will be omitted.

[0071] Inside the group supervisory control device 2a of the elevator system of the second embodiment, a power consumption data memory 27 is provided instead of the operation data memory 14 of the first embodiment, and a power consumption data memory 27 is provided instead of the current operation data detection unit 17. Current power consumption data memory 28 .

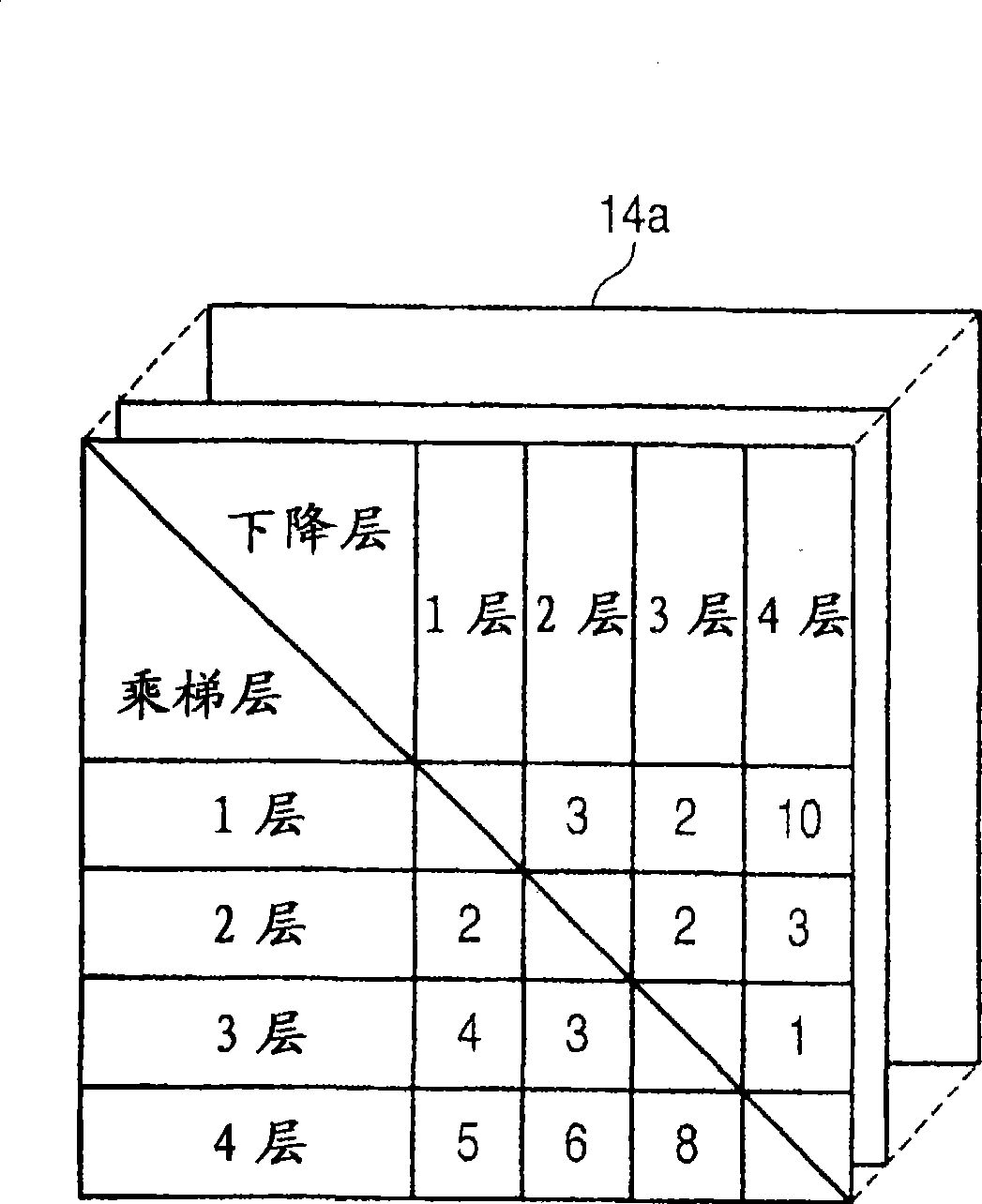

[0072] Inside the power consumption data memory 27, such as Figure 8 As shown, the past power consumption data consumed by the motors 4 of all the elevators 1a, 1b, and 1c generated in each period of a fixed period unit such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com