Gas landmark decomposition product quickly detecting device and method of SF6 equipment after failure

A technology of equipment failure and SF6, which is applied in the field of electric power safety production, can solve problems such as personal health and safety threats, data overrun, inflexibility, etc., and achieve the effects of rapid recovery of detection capabilities, improvement of work efficiency, and reduction of recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

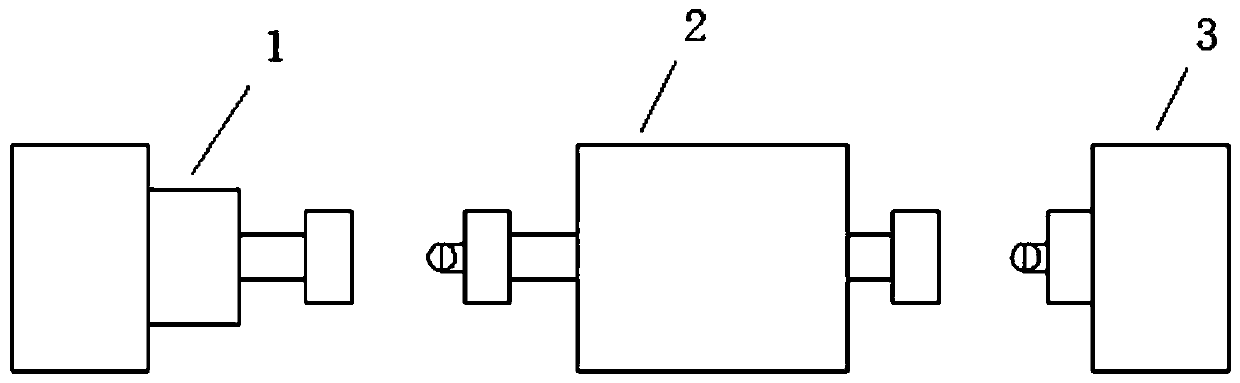

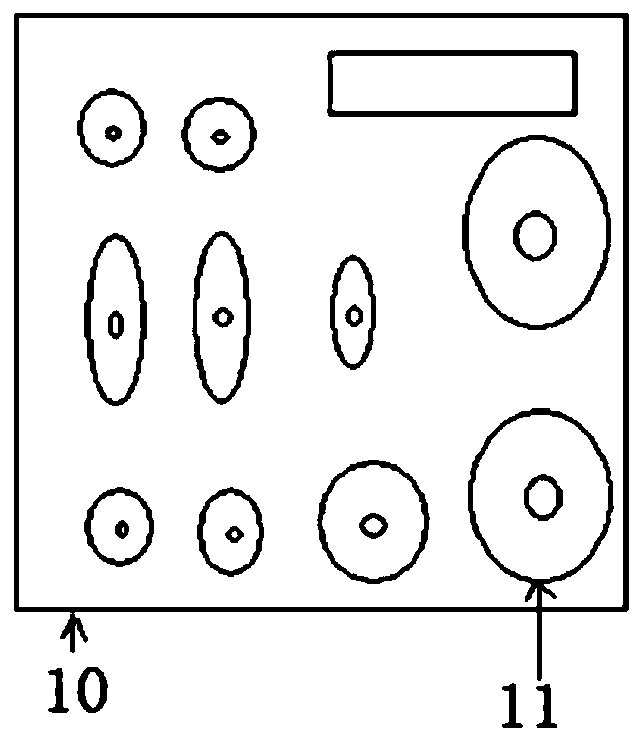

[0057] refer to Figures 1 to 10 As shown, a rapid detector of gas marker decomposition products after SF6 equipment failure, which includes:

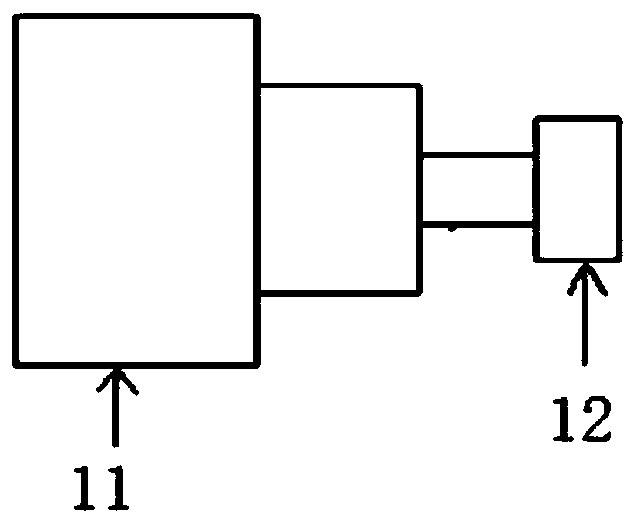

[0058] Connector combination 1, including multi-type connectors 11 connected to SF6 equipment, each multi-type connector is connected to a quick-plug connector female 12;

[0059] The detection host 2 includes a detection host housing 20 with a detection cavity, an air intake quick-plug connector male 201 and an exhaust gas quick-plug connector female 202 connected to the detection host housing, and the air intake quick-plug connector male 201 is located at the detection host The air inlet position is connected with the quick plug joint female 12, and is used to introduce SF6 decomposition product gas. The H2S sensor 23, the SO2 sensor 24, the single-chip microcomputer 28, and the power module 29 are arranged in the detection chamber. A display screen 22 and a power switch 21 are provided, and the power supply module supplies power to...

Embodiment 2

[0090] refer to Figure 6 and Figure 9 Shown, a kind of SF6 equipment failure after the rapid detection method of gas marker decomposition products, using a kind of SF6 equipment failure in embodiment one gas marker decomposition product fast detector for detection, including the following steps:

[0091] First, the active air pump is turned on, the air enters the gas mixing chamber / valve through the gas pipeline through the controllable flow valve, and the measured gas also enters the gas mixing chamber / valve through the gas pipeline through the controllable flow valve;

[0092] Secondly, the measured gas is quickly detected through the sensor, and the single-chip microcomputer processes the measurement data and displays the measurement results on the display;

[0093] Finally, the measured gas is discharged through the gas outlet of the detection host, and the tail gas is collected through the gas collection device, or the tail gas is processed through the filter adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com