Device for preparing isocyanate by pyrolyzing aminoalkyl esters

An aminoalkanoate and isocyanate technology, applied in the preparation of carbamate and other directions, can solve the problems of easy blockage of pipelines, difficult to achieve industrialized scale production, lack of economic advantages, etc., to overcome short service life, improve conversion rate and reaction rate. the selective effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

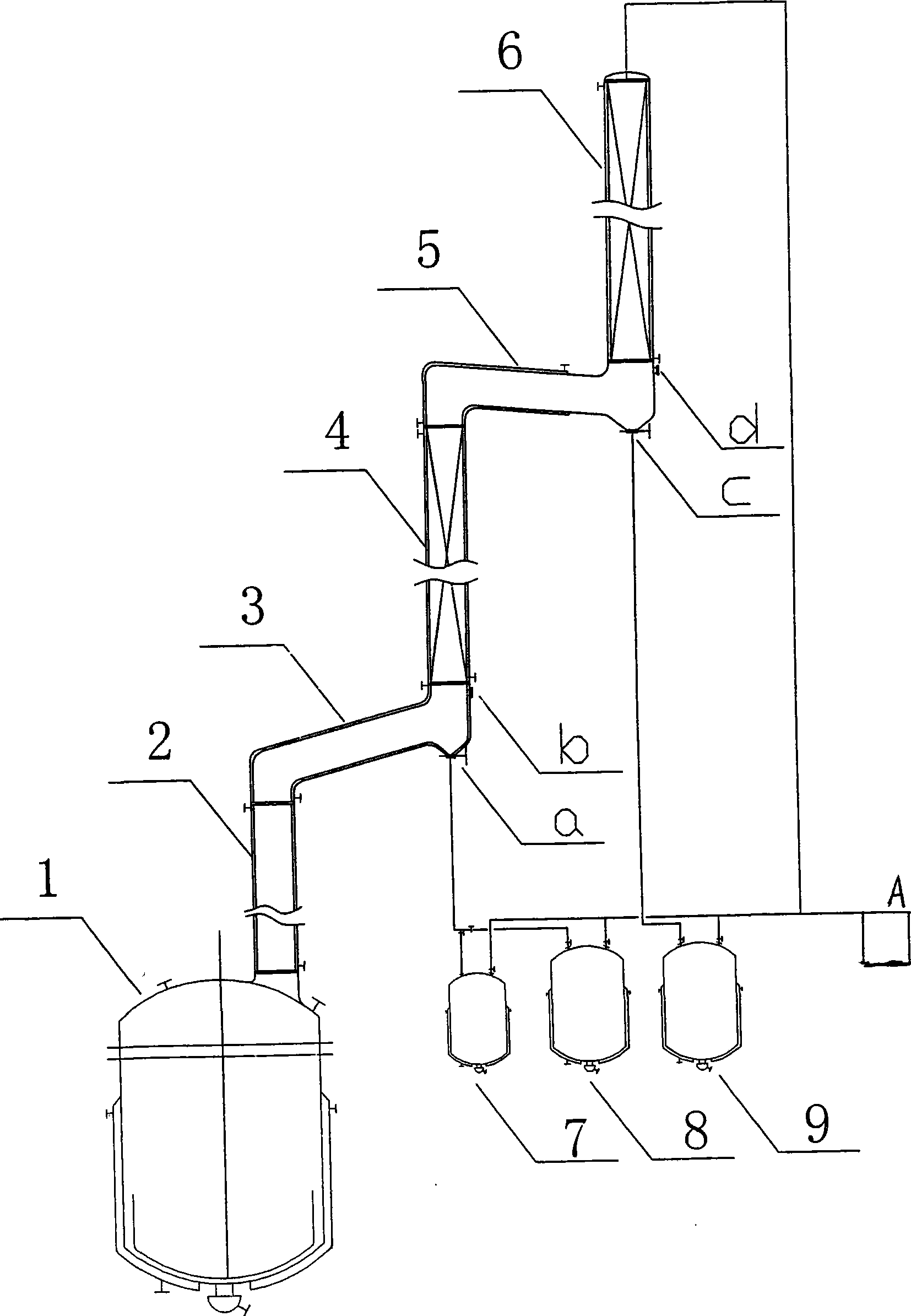

[0012] The main structure of this embodiment includes a pyrolysis reactor 1, three upper, middle and lower columns 6, 4 and 2, two oblique and horizontal H distillation heads 3 and 5, and three receiving tanks 7 and 8 on the left, middle and right and 9; the top of the pyrolysis reactor 1 is connected to the bottom of the lower sieve plate column 2 through the tower support, and the top of the lower sieve plate column 2 is connected to the bottom of the oblique H distillation head 3, and the oblique H distillation The top of the head 3 is connected to the bottom of the middle packing tower column 4, and the discharge port of the inclined H distillation head 3 is respectively connected with the product left receiving tank 7 and the middle receiving tank 8 through the material pipeline, and the top of the middle packing tower column 4 is connected to the The bottom end of the horizontal H distillation head 5 is connected, the top of the horizontal H distillation head 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com