Zirconium oxide base metal ceramic material and preparation method thereof

A ceramic material and zirconia-based technology, which is applied in the field of zirconia-based cermet materials and its preparation, can solve the problems of short service life and low heat exchange efficiency of heat exchange tubes, and achieve the effect of overcoming short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

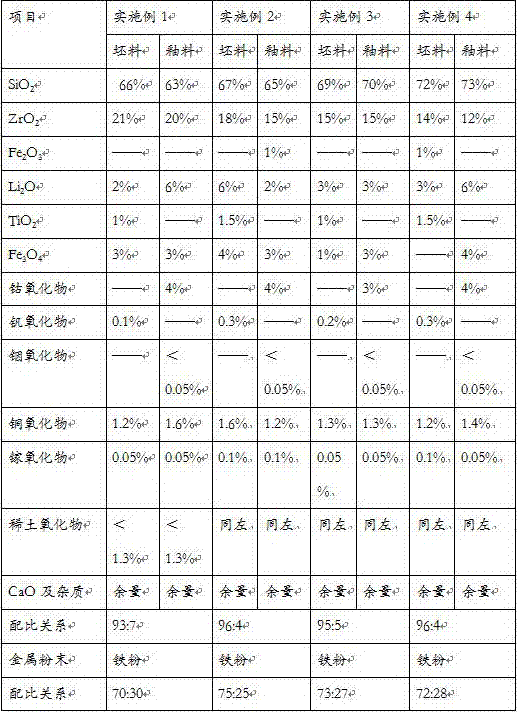

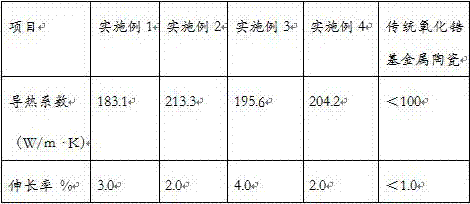

Examples

preparation example Construction

[0028] Further, the preparation method of the ceramic powder comprises the following steps:

[0029] Step 1. The blank is prepared by using the existing technology, and then the surface of the blank is evenly coated with glaze, and then fired into a fired body at a temperature below 1300°C;

[0030] Step 2. Grinding the fired preform together with zinc oxide into a powder with an average particle size of less than 50 μm to obtain ceramic powder, wherein the mass fraction of zinc oxide added is not higher than 3.5% of the mass fraction of the fired body .

[0031]In the zirconia-based cermet material of the present invention, the preparation method of the zirconia-based cermet material comprises the following steps:

[0032] Step 1. Take the designed amount of metal powder and ceramic powder and place them in a high-speed ball mill for mixing and grinding for 2-4 hours. The speed of the high-speed ball mill is 400rad / min, and then put them in a high-speed mixer and mix them ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com