Fiber grating pressure sensor free from temperature influence

A technology of pressure sensor and optical fiber grating, which is applied in the field of sensors, can solve problems such as temperature and pressure cross-sensitivity, and achieve the effects of large measurement range, easy process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

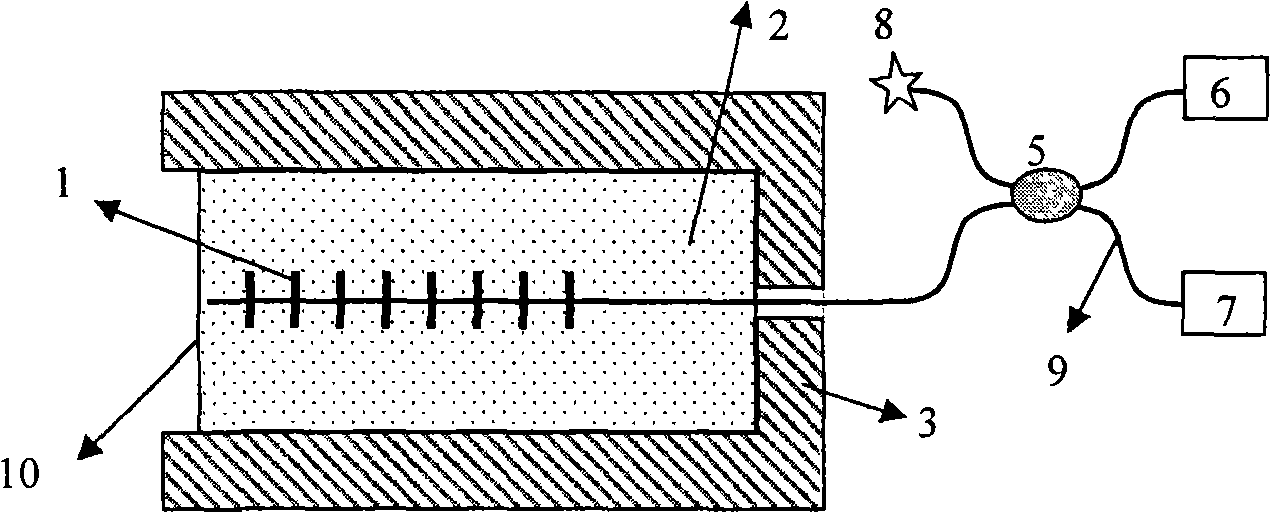

[0020] Embodiment 1: see attached image 3 , the fiber grating adopts a fiber Bragg grating 1, and the fiber Bragg grating 1 is packaged in a metal tubular housing 3 with one end open, and one end of the fiber grating 1 is passed through a small hole in the center of the unopened end face of the tubular housing 3 and connected to a single-mode optical fiber 9 It is connected with 2×2 3dB fiber optic coupler 5; there are four ports on both sides of the fiber coupler 5, and the other port on the side connected to the fiber coupler 5 is connected to the optical fiber refractive index matching solution 8 through a single-mode fiber 9 Middle; two ports on the other side of the fiber coupler 5, one end is connected to the broadband light source 6 through a single-mode fiber 9, and the other end is connected to the demodulation system 7 through a single-mode fiber 9; the fiber grating 1 is packaged by filling the polymer acrylate 2 in Tubular housing 3.

[0021] The assembly steps a...

Embodiment 2

[0022] Embodiment 2: see attached Figure 4 , the structural diagram of the fiber grating pressure sensor using packaging method 2. The packaging steps are as follows: (1) process the alloy tubular housing 4 and the protective back cover 11 so that the two can be connected by sealing threads, and the inner wall of the tubular housing 4 is also ground into a rough surface; (2) remove the fiber Bragg grating 1 package Part of the coating layer; (3) placing the fiber grating 1 on the central axis of the tubular housing 4 and pre-stretching it, and then encapsulating the prepared polymer polyurethane 2 in the tubular housing 4; (4) placing A protective back cover 11 is added to the tubular casing 4, and the encapsulated polymer 2 is cured for calibration measurements. Its measurement method and image 3 Same as shown.

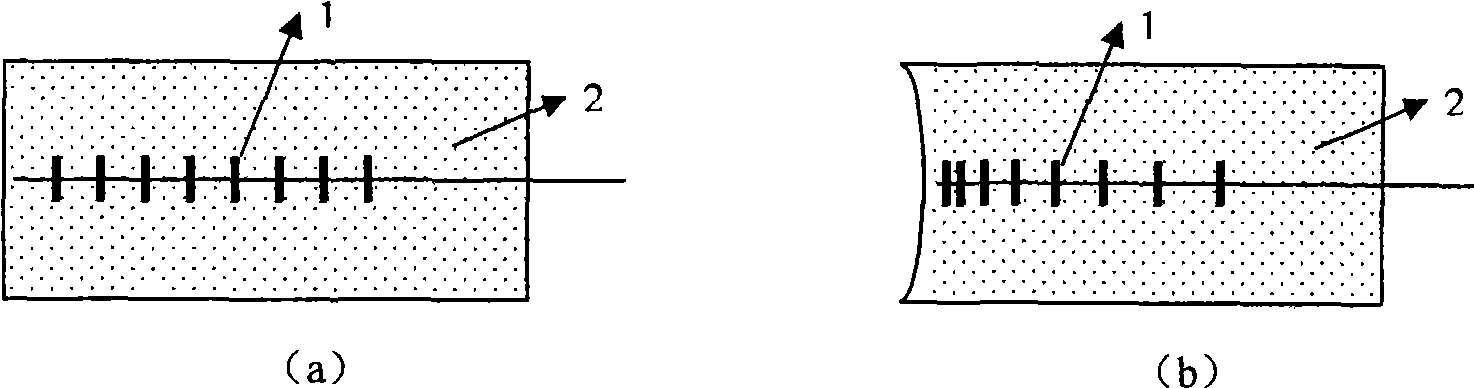

[0023] Compare image 3 shown in Example 1 and Figure 4 From the shown embodiment 2, it can be concluded that the main difference between the two lies in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com