Electrode guiding wire slurry outside an oxygen sensor and manufacturing method thereof

A technology of oxygen sensor and manufacturing method, which is applied in the direction of material analysis, instruments, and scientific instruments through electromagnetic means, can solve the problems of poor corrosion resistance and high cost, and achieve the goals of reducing raw material costs, good film formation, and shortening working temperature the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

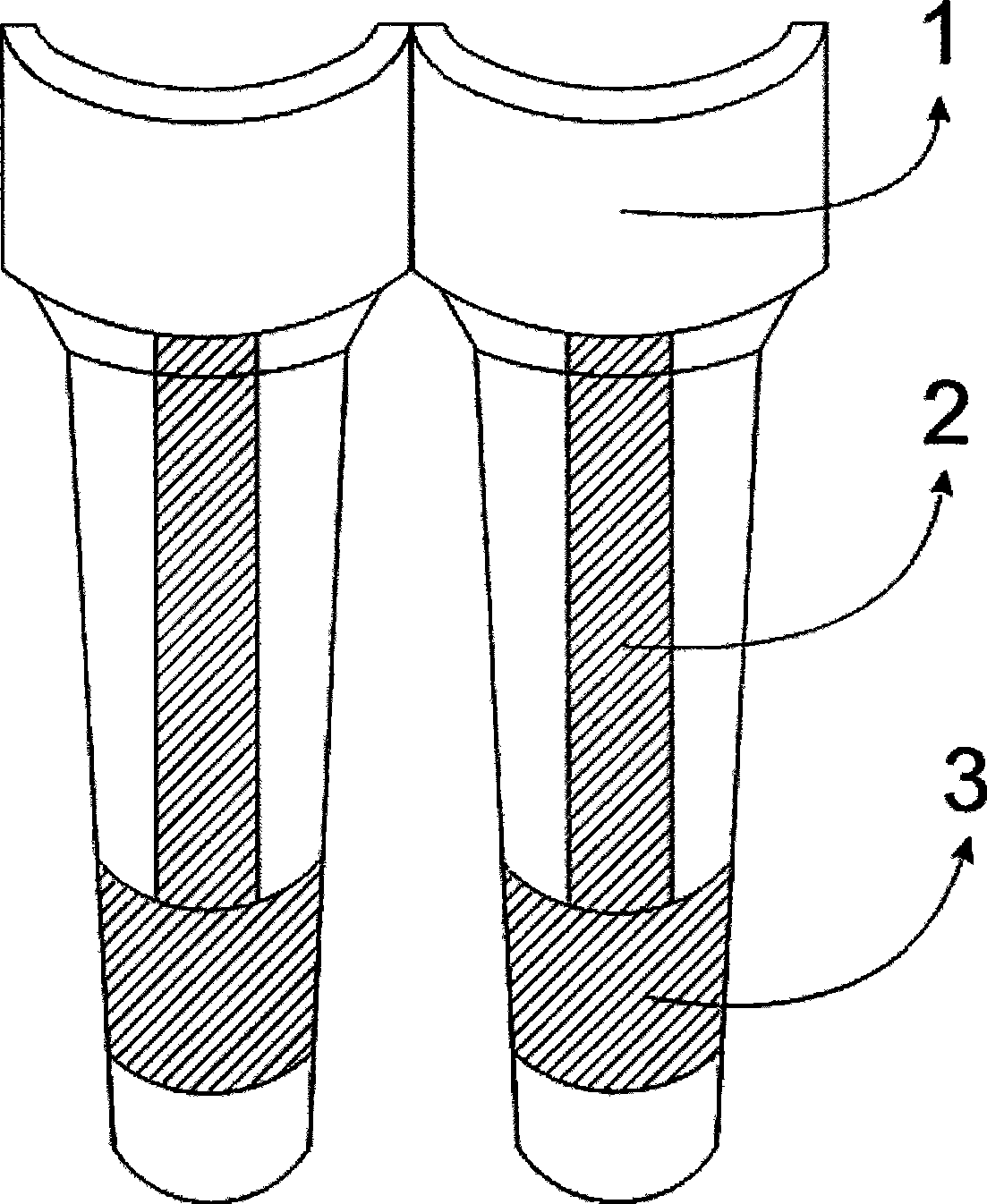

[0017] The core idea of the present invention is: mix platinum powder, gold powder and tungsten powder evenly to make a slurry, and then use a micro-dispenser to coat the slurry with two symmetrical electrode lead-out lines on the surface of the sleeve-shaped zirconia substrate , After high-temperature sintering, it is integrated with the platinum electrode to form the outer electrode of the oxygen sensor.

[0018] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] The invention provides a slurry for the lead-out wire of an oxygen sensor external electrode and a new method for its manufacture. The specific implementation steps are as follows:

[0020] A. Fully mix platinum powder, gold powder and tungsten powder with a particle size range of 0.5-5 μm and a weight ratio of 60%, 30% and 10% in a mortar, and then add 20% of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com