Anomaly detection method of UV photoresist hardening platform

A photoresist and anomaly technology, which is applied in the field of abnormal detection of UV photoresist hardening machines, can solve problems such as photoresist flow, and achieve the effect of improving the yield of hardened products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, below in conjunction with a preferred embodiment of the present invention, the detailed description is as follows:

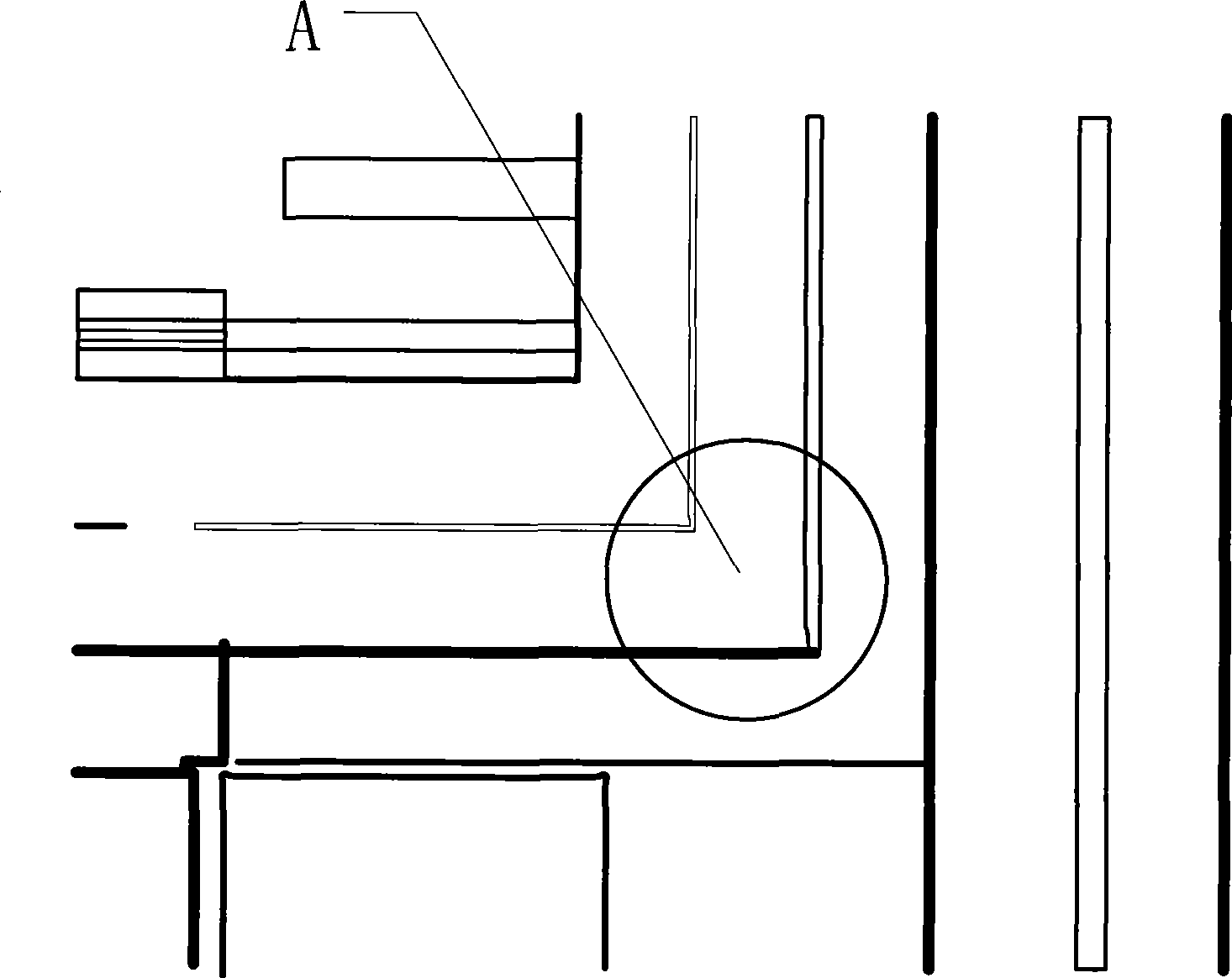

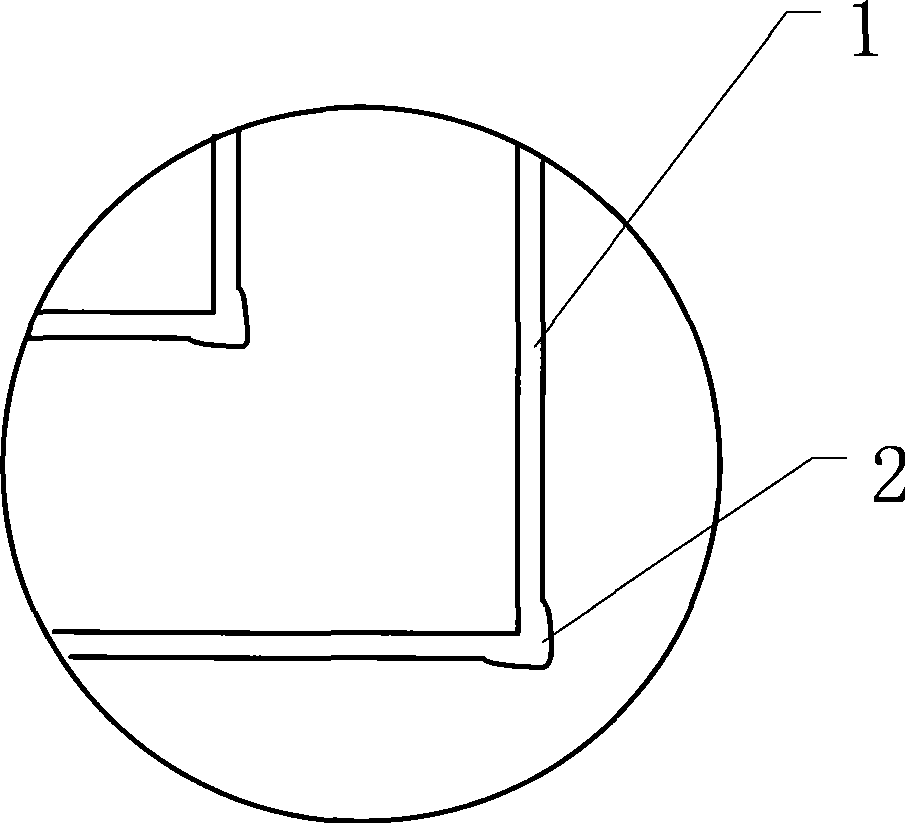

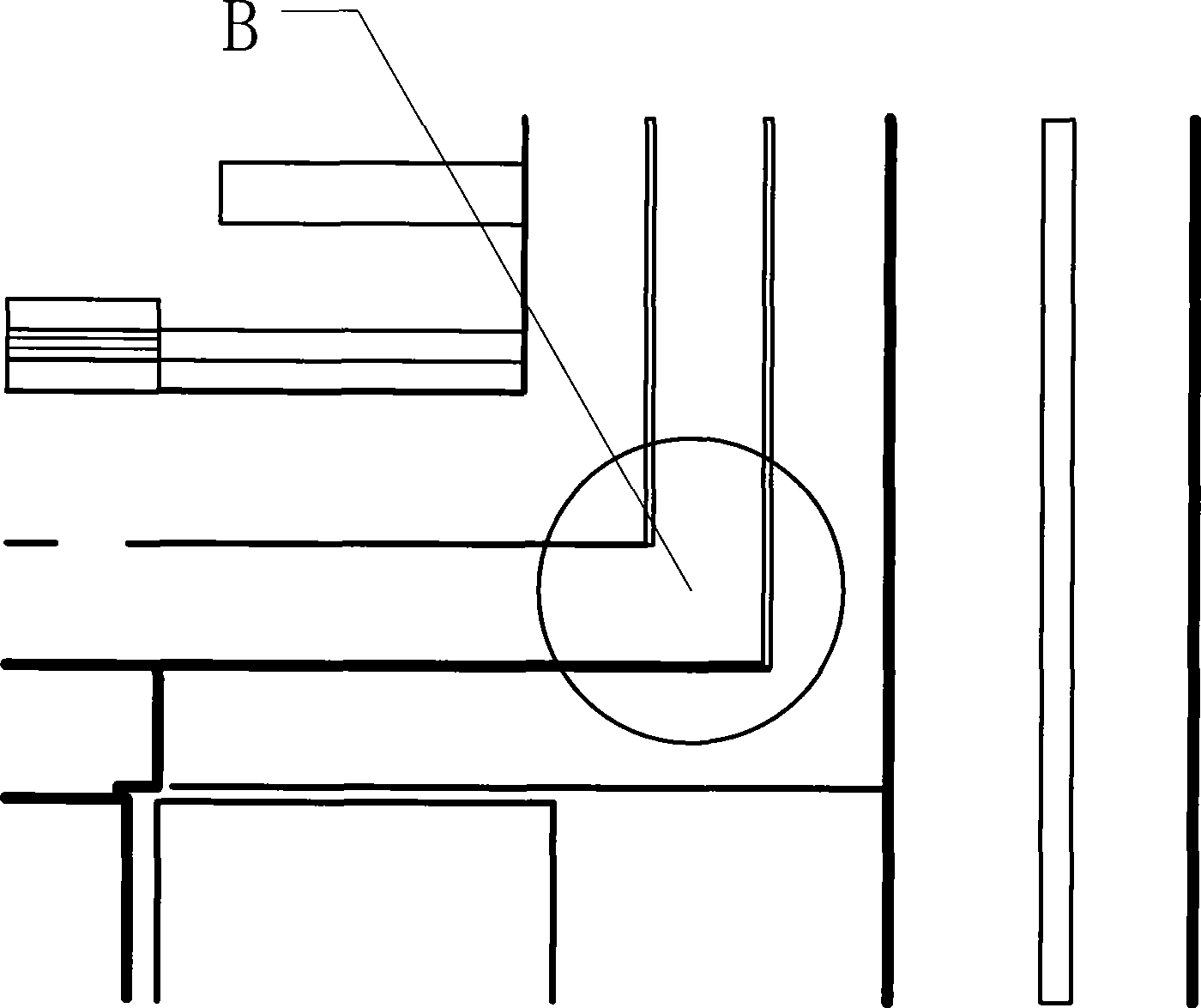

[0021] In the pre-sequence process of semiconductor manufacturing, photoresist is evenly coated on the wafer with a very thin thickness to make the silicon wafer photosensitive, and then the lens and the photolithographic mask with the designed circuit are used to process the photoresist under UV light. Under the irradiation, the circuit pattern is copied to the surface of the silicon wafer and developed. Before subsequent etching or ion implantation, the photoresist film needs to be hardened by a UV photoresist hardening machine. However, during the processing of the UV photoresist hardening machine, there are sometimes abnormal situations. Due to the influence of abnormalities such as too weak UV light or too high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com