Method for manufacturing helix line slow-wave system of wide frequency band traveling wave tube

A technology of slow wave system and manufacturing method, which is applied in the manufacture of electrode systems, the manufacture of discharge tubes/lamps, the manufacture of ships or lead-in wires, etc. efficiency, improve production accuracy, and reduce labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

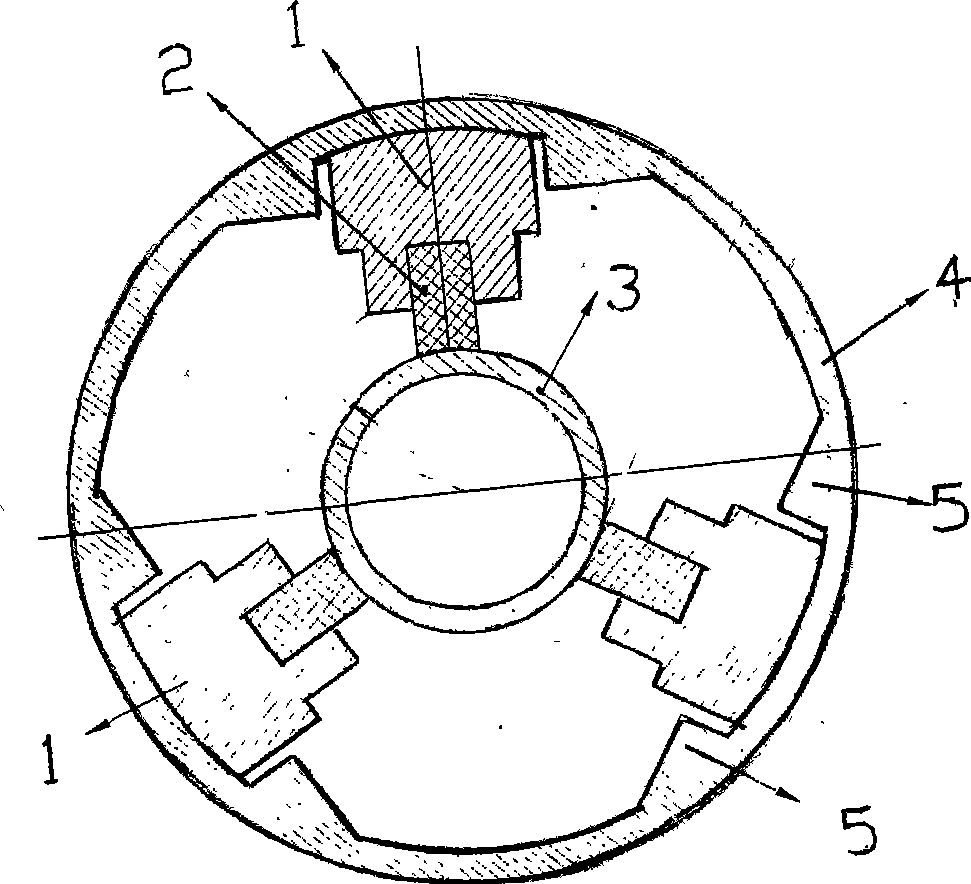

[0014] refer to figure 1 , showing the sectional view of the helical slow wave system. In the figure 1 is the metal load, the clamping rod 2 is inserted in the metal load longitudinal groove 1-1, the middle part is the helix 3, the outermost is the total metal tube shell 4, and in the total metal load There are protrusions 5 inside the tube shell.

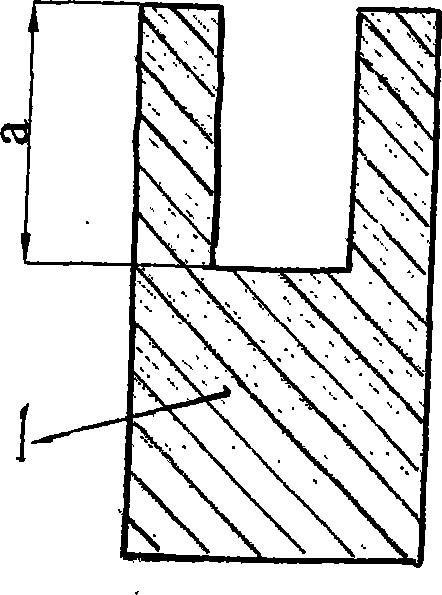

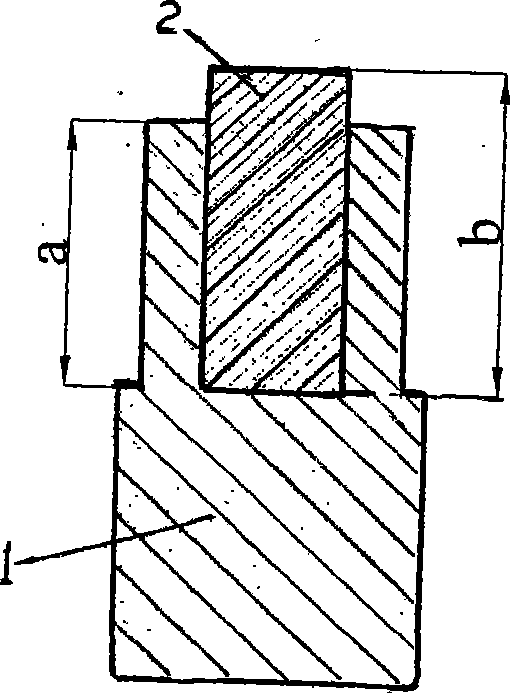

[0015] refer to figure 2 , image 3 , represents the cross-sectional view of the metal load after orthopedic shaping, the longitudinal groove on the metal load in the figure is 1-1, the depth of the groove is a, and the height of the clamping rod fixed inside is b.

[0016] refer to Figure 4 , represents the assembly assembly of the helical slow wave system. The clamping rod 6 in the center of the figure is a tool core rod used to protect the helix and fix it to the fixture during the assembly process. It must be removed after assembly. The core rods 7 that three process assemblings are used also will be taken away after asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com