A luminous module encapsulation method

A light-emitting module and packaging method technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of difficult control of white light uniformity and poor yield rate, and achieve the effect of avoiding yellow halo phenomenon and simple and fast manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

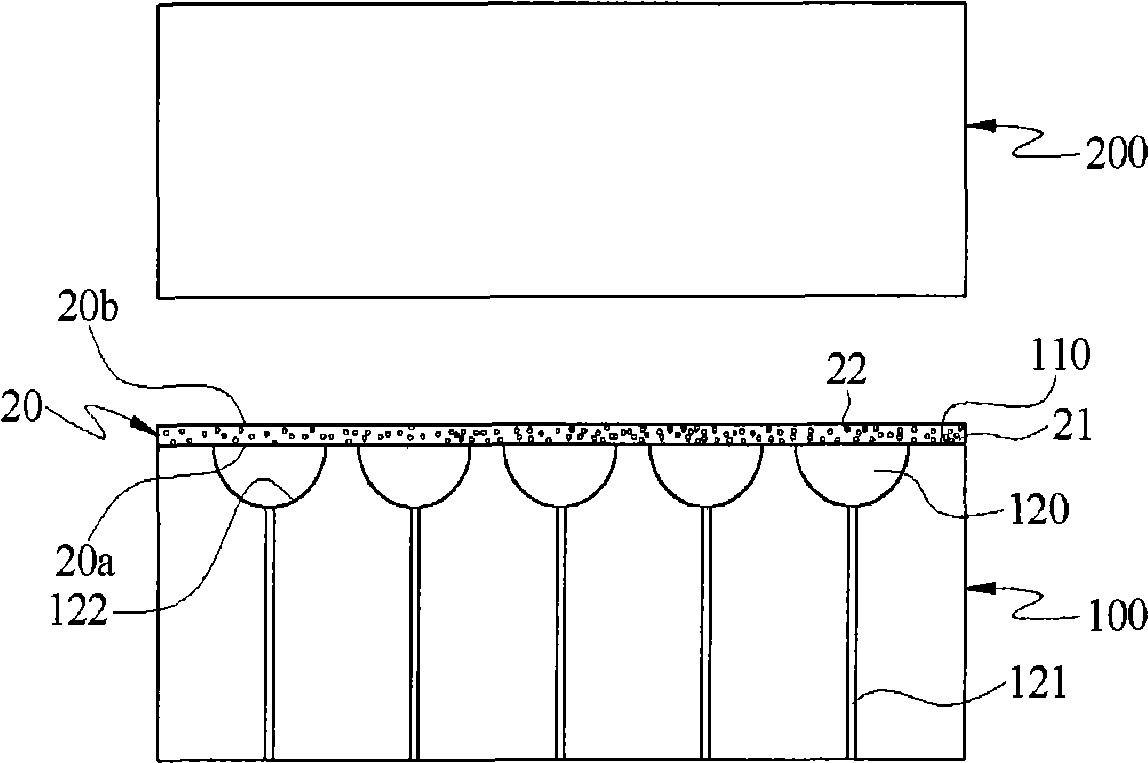

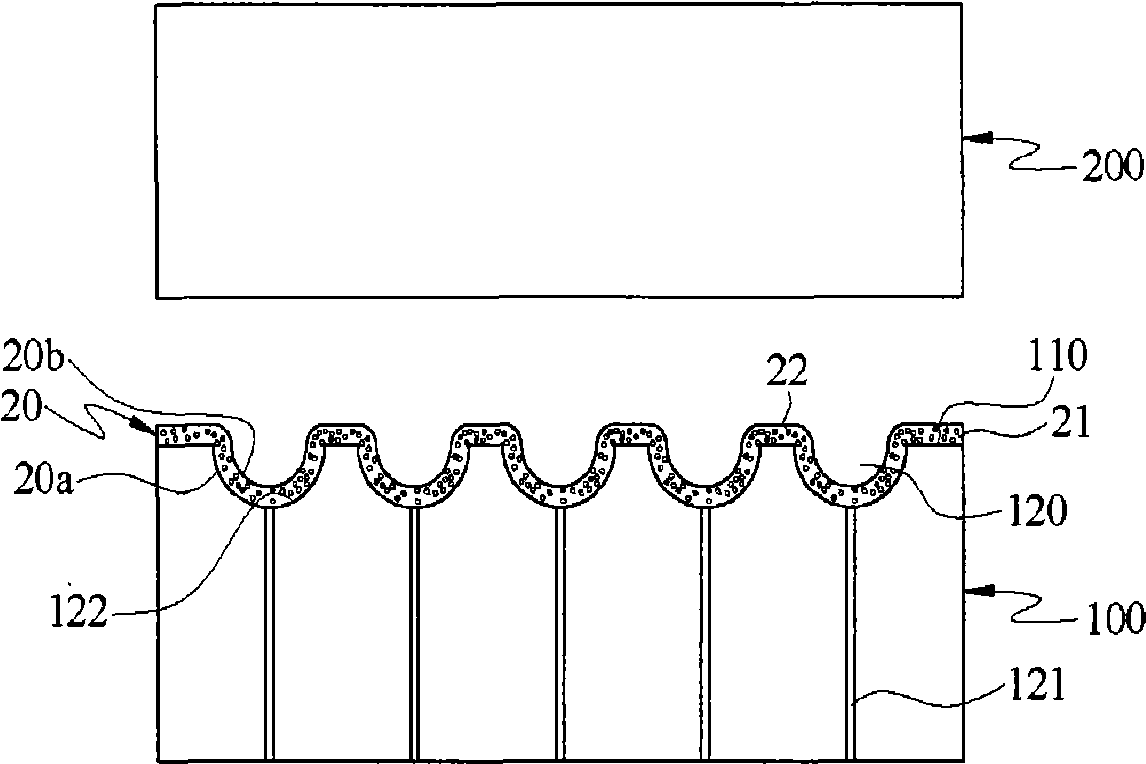

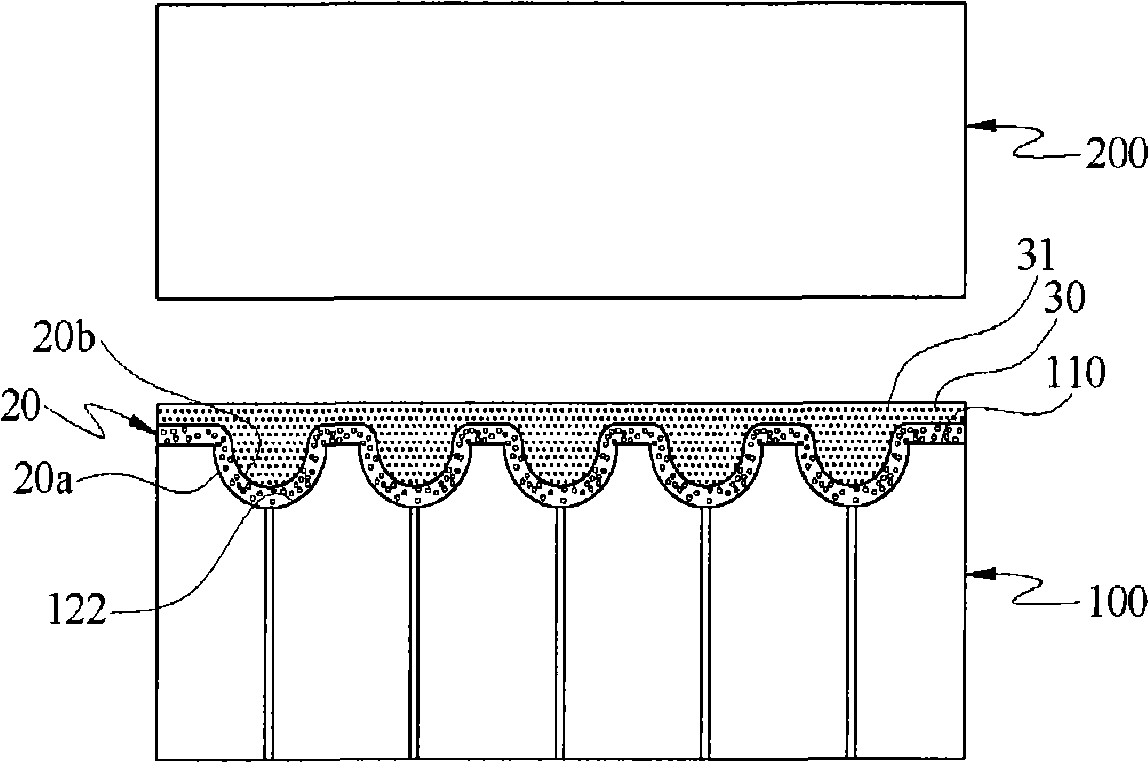

[0045] " Figure 1A "," Figure 1B "," Figure 1C "," Figure 1D "," Figure 1E "," Figure 1F "and" Figure 1G ” is a schematic flowchart of the packaging method of the light emitting module according to the first embodiment of the present invention.

[0046] The packaging method of the light emitting module of this embodiment is applicable to a molding mechanism having an upper mold 100 and a lower mold 200 , wherein the surface 110 of the upper mold 100 has more than one mold cavity 120 .

[0047] The mold cavity 120 is disposed on the surface 110 of the upper mold 100 facing the lower mold 200 . The upper mold 100 also has a plurality of through holes 121 . The through hole 121 is arranged one-to-one with the mold cavity 120 and communicates with the mold cavity 120 .

[0048] Please refer to" Figure 1A ", according to the first embodiment of the packaging method of the light-emitting module of the present invention, first, the fluorescent film 20 is placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com