Boost converter input ripple current reduction circuit

A technology for boost converters and boost inductors, applied in electrical components, photovoltaic power generation, high-efficiency power electronics conversion, etc., can solve problems such as expensive, large systems and devices, and undesired stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

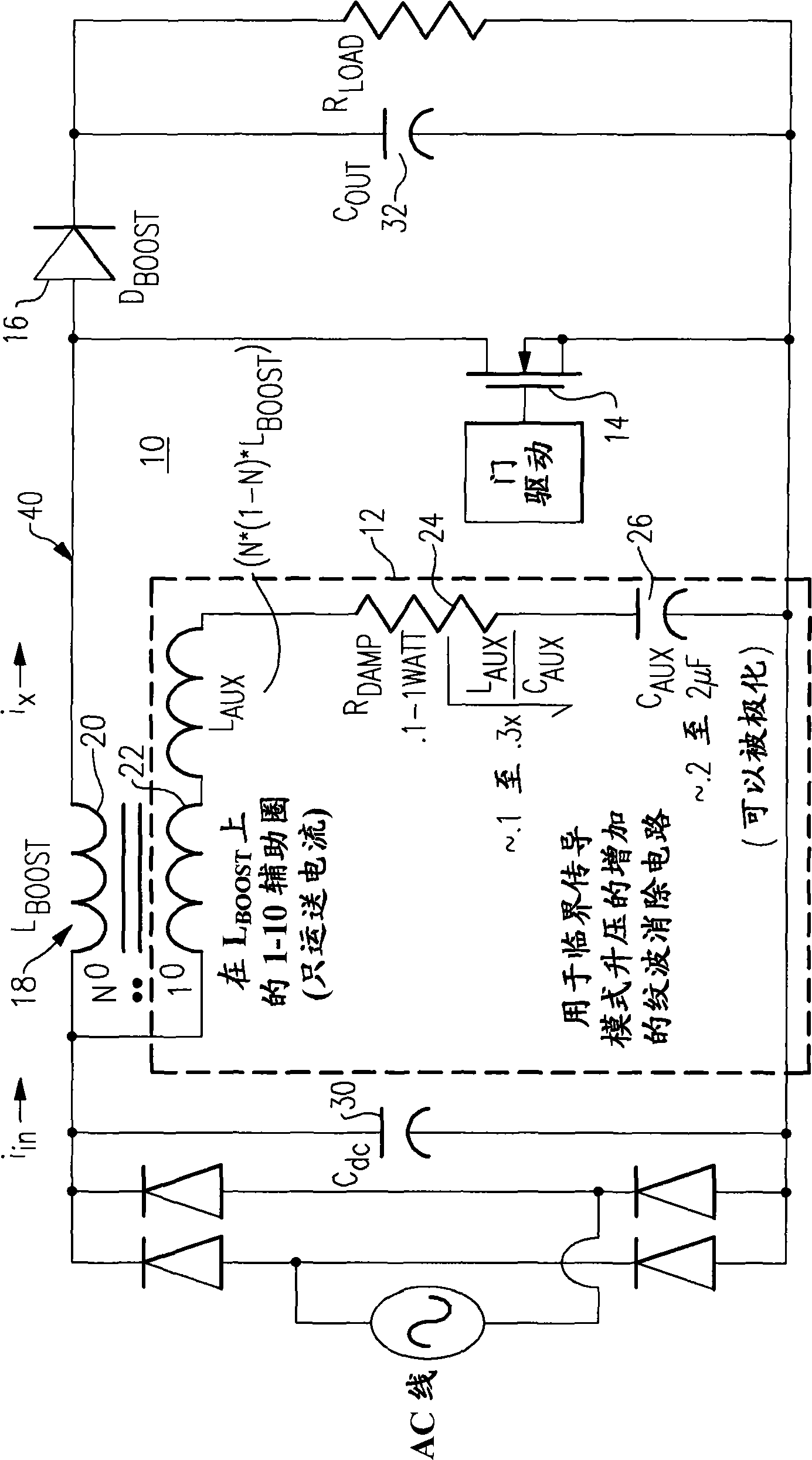

[0030] figure 1 A boost converter 10 including a boost inductor value reduction circuit 12 according to one embodiment of the invention is illustrated. The boost inductor value reduction circuit 12 is a lightweight, inexpensive and compact ripple cancellation circuit when compared to conventional filter structures. The boost inductor value reduction circuit 12 operates to generate a high frequency current signal that substantially cancels the high frequency ripple current that is conducted back to the AC line input side of the boost converter 10, said high frequency ripple The ripple current is generated by the switching components of the boost converter 10 . According to one embodiment, it can be seen that the switching components of the boost converter 10 include a MOSFET 14 and a boost diode 16 .

[0031] Although boost converter 10 is shown with an AC line input, the invention is not so limited; and it will be appreciated that the principles described herein apply equall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com