Process adopting sugarcane as raw material to prepare pure brown sugar molasses

A brown molasses, pure technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of perishable, discolored, inedible, etc., and achieve the effect of convenient diet, preservation, and rich nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

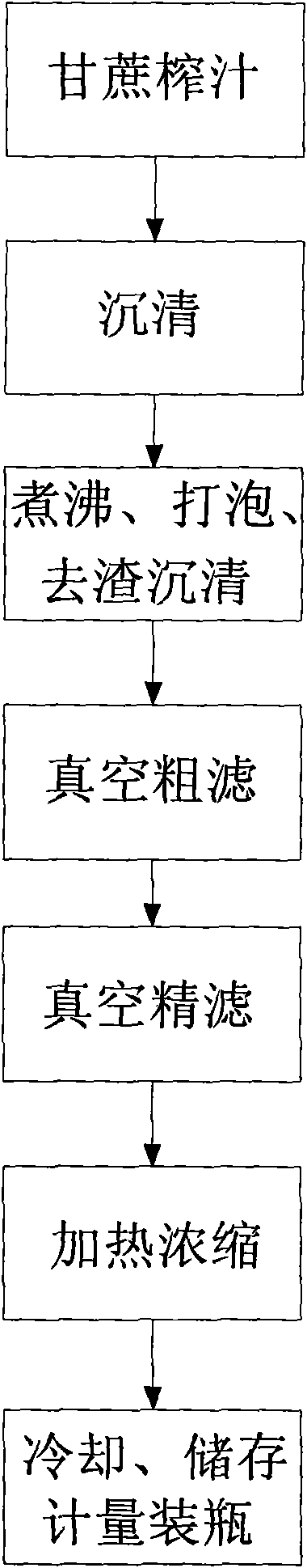

[0015] The present invention will be described in more detail below in conjunction with specific embodiments and the drawings.

[0016] Refer to figure 1 , A process for producing pure red molasses using sugarcane as raw material. First, 850kg of sugarcane juice is squeezed with 1000kg of sugarcane as raw material; then the squeezed sugarcane juice is subjected to sedimentation and deslagging to obtain 820kg of pure sugarcane juice; The obtained pure sugarcane juice is heated with steam for no more than 30 minutes. During this period, the pressure is controlled at 0.2~0.3mpa, and the temperature of the cane juice is controlled at 80~95℃. After frothing and removing slag, 800kg of pure molasses liquid is obtained. The sugar concentration is 10-17%; after the above operation is completed, vacuum suction the stainless steel sedimentation tank to clear the sediment, and perform vacuum coarse filtration. The filter membrane used is 50-200 mesh to obtain 750 kg of sugar cane molasses; ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com