Oscillating spiral dry separator

A vibrating screw and sorting machine technology, which is applied in the field of dry separation of other fine-grained minerals, can solve problems such as inability to achieve effective separation, unsatisfactory separation effect, and contamination of target minerals, and achieve good separation effect and high separation efficiency. The selection is stable and reliable, and the effect of energy saving and consumption reduction is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

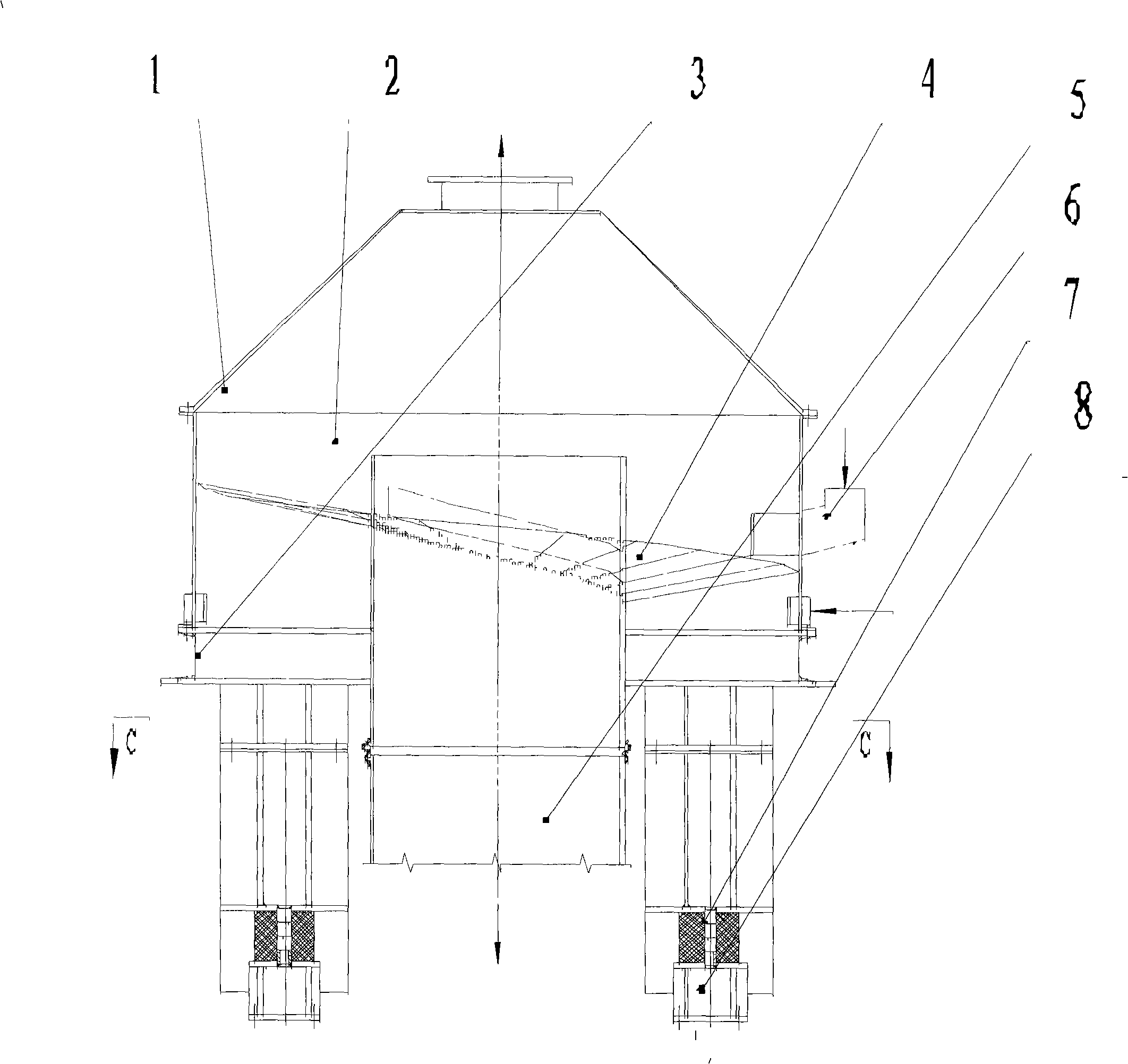

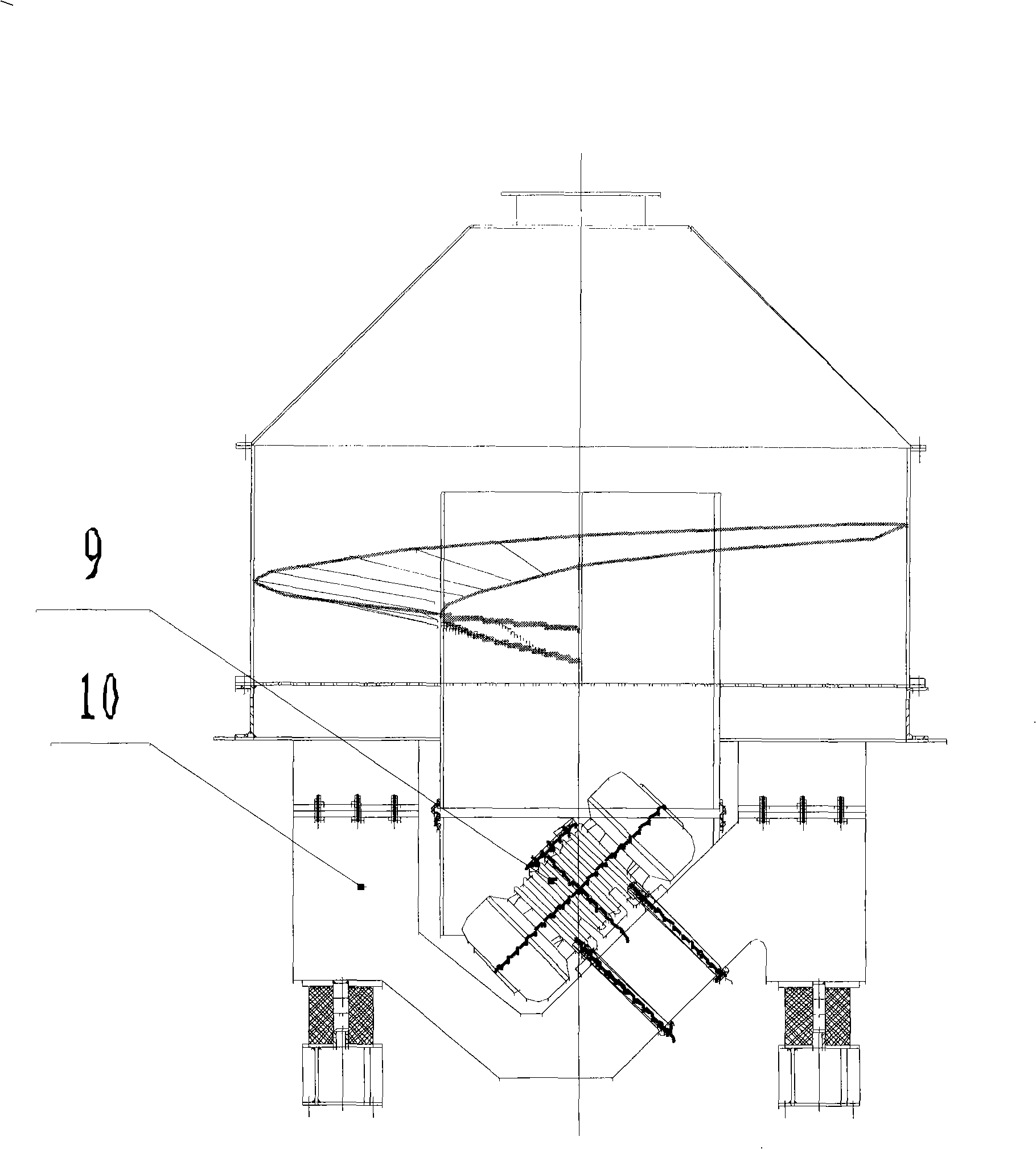

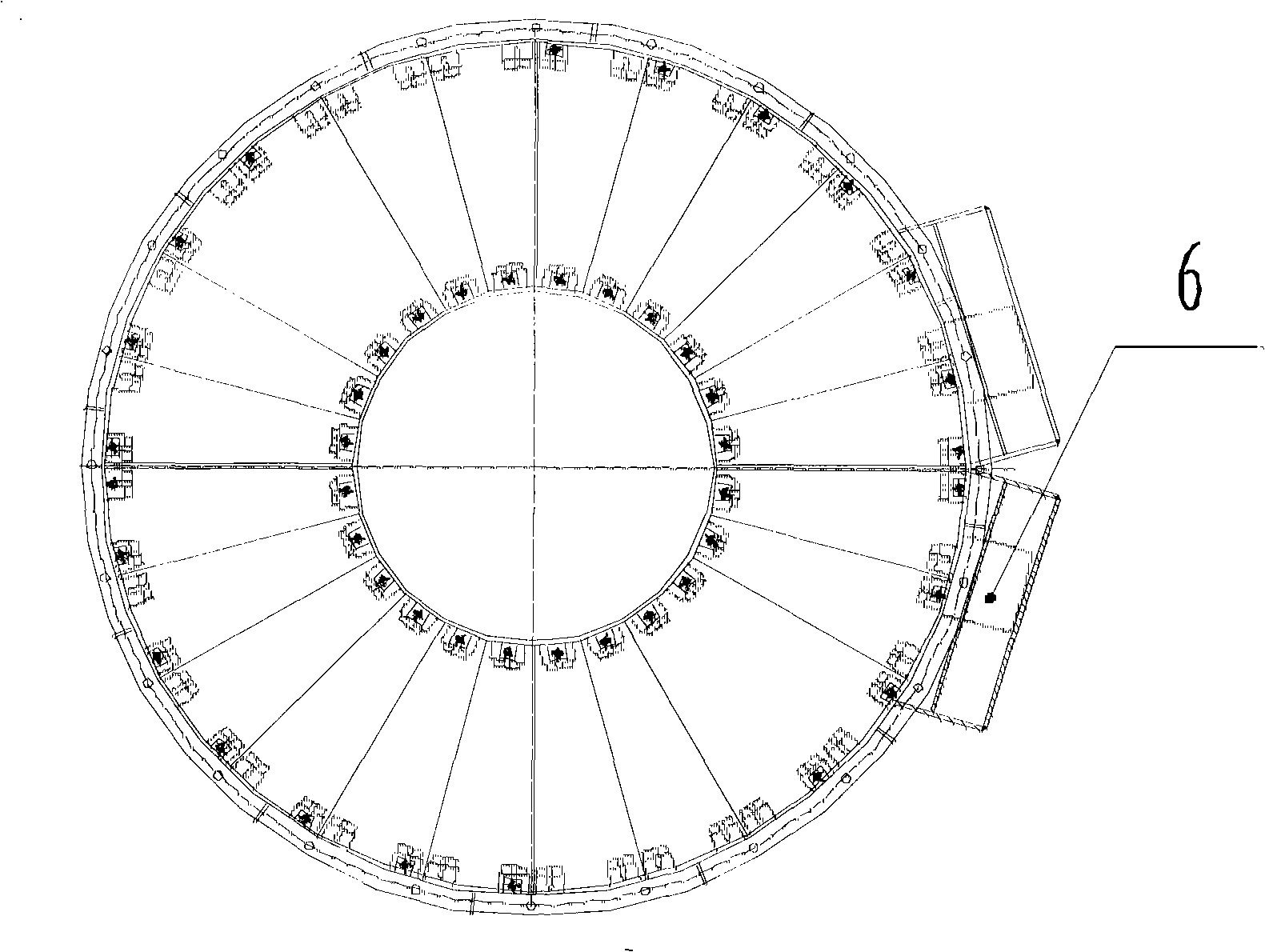

[0014] figure 1 As shown, the vibrating spiral dry separator of the present invention is mainly composed of a spiral cylinder body 2, a vibrating platform 3, a spiral groove bed surface 4, a chute 5 and a feeding nozzle 6. The spiral groove bed surface 4 is arranged on the inner wall of the spiral cylinder body 2, and has a certain longitudinal inclination angle and a transverse inclination angle, and is high on the outside and low on the inside. In the dust collection cover 1, the top of the dust collection cover 1 is provided with an air inlet corresponding to the middle hole surrounded by the spiral groove bed surface 4; The discharge nozzle 6 is provided with an air inlet pipe for supplying air to the bottom of the spiral groove bed surface 4. The bottom end of the spiral cylinder 2 is provided with a ring-shaped vibration platform 3 with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com