Double-sleeve oscillating jetter

A technology of spray cleaning device and swinging back and forth, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of inability to meet rapid cleaning, dew condensation on workpieces, uneven solid particles, etc., to reduce consumption and Cleaning cost, improving area and efficiency, reducing the effect of workpiece icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make it easy for those skilled in the art to deeply understand the structure and functional effects of the present invention, a specific embodiment is now listed and described in detail in conjunction with the accompanying drawings as follows.

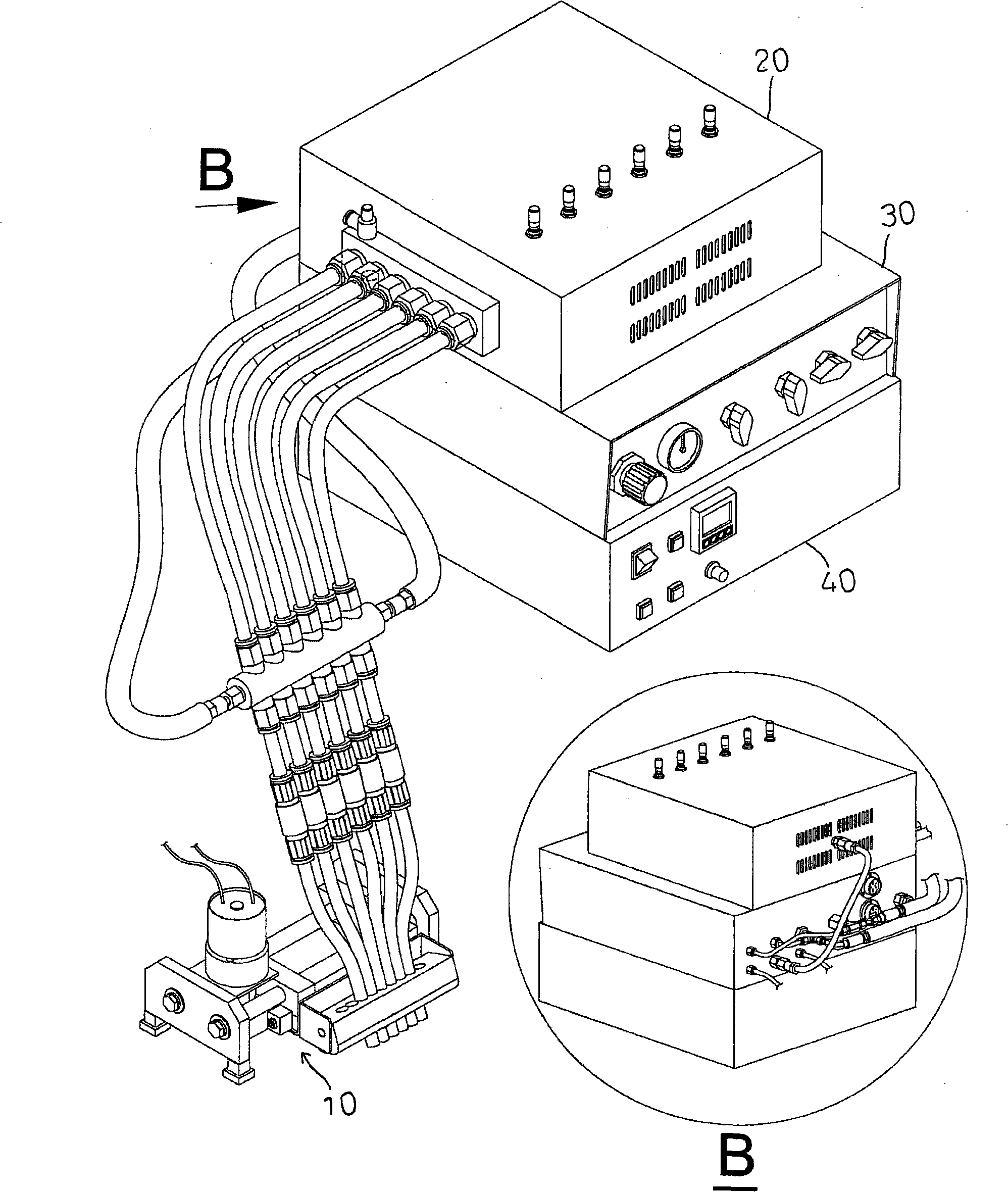

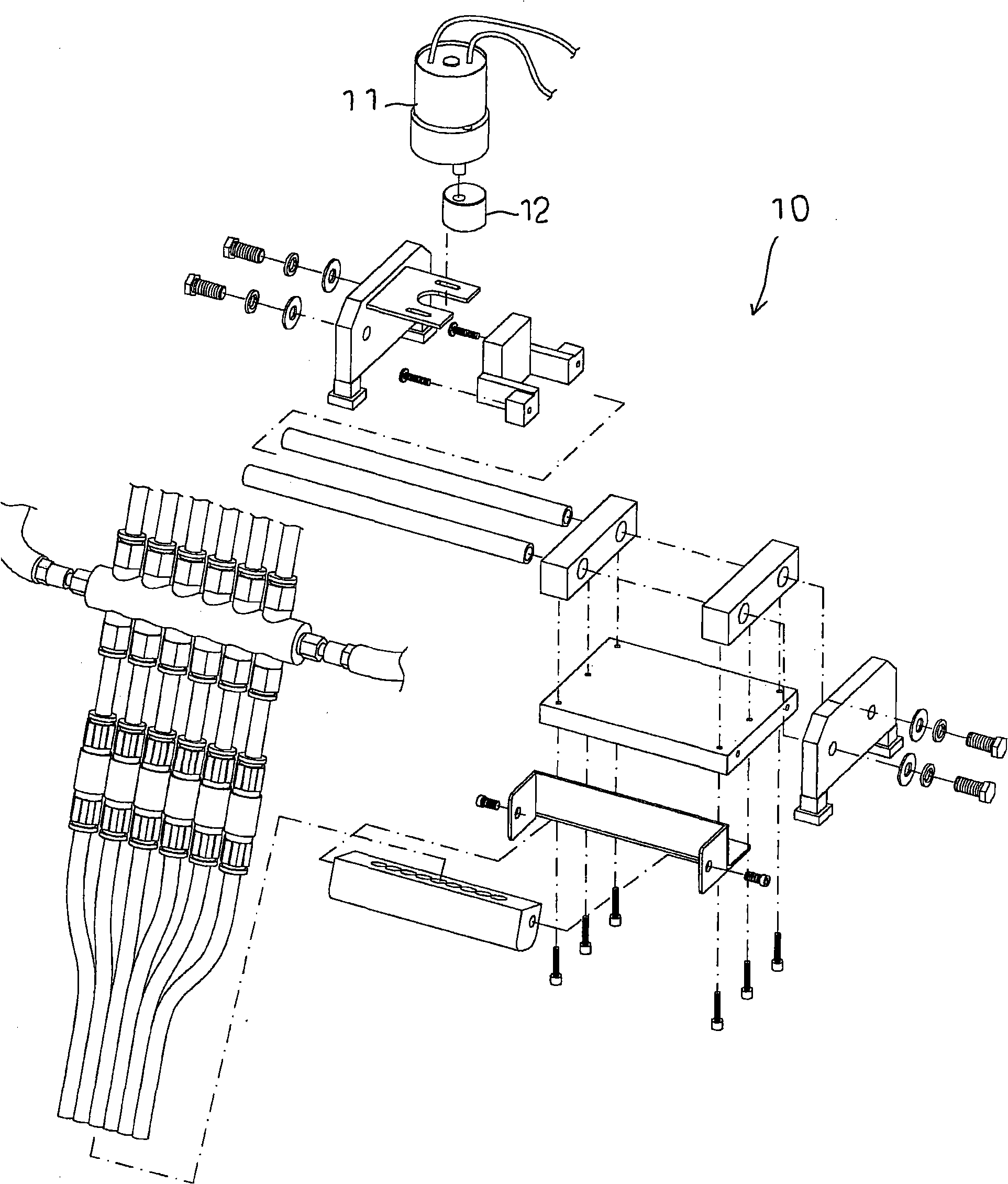

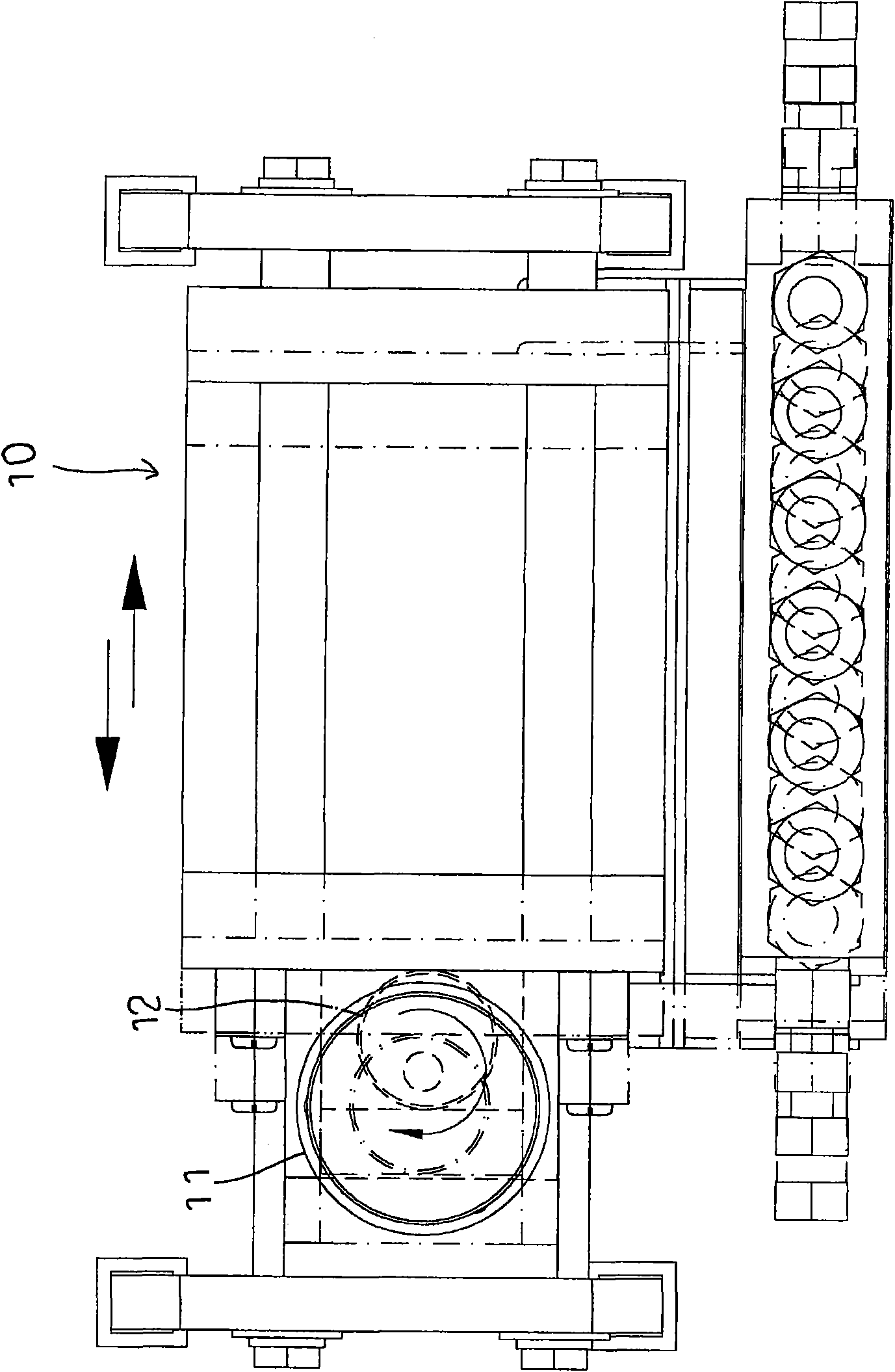

[0029] A double-pipe back and forth swinging spray washing device that can control the size of solid carbon dioxide particles and prevent pipe bursting and condensation, please refer to figure 1 , which is a perspective view of the combination of the present invention, where B is a partial rear view of the device. The spray cleaning device is mainly composed of a swing mechanism 10, a carbon dioxide snowflake generating mechanism 20, a hot air flow generating mechanism 30, and a control unit 40; the spray cleaning device is a high-efficiency large-area spray cleaning device; wherein, please refer to figure 2 , image 3 , which is a three-dimensional decomposition and a schematic diagram of the swing state of the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com