Inverse control system of trolley locomotive

A technology for inverter control and power supply locomotives, applied in power lines, vehicle parts, transportation and packaging, etc., can solve the problems of current impact, poor track return, low power supply terminal voltage, etc., to avoid current impact and avoid contact jitter , adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

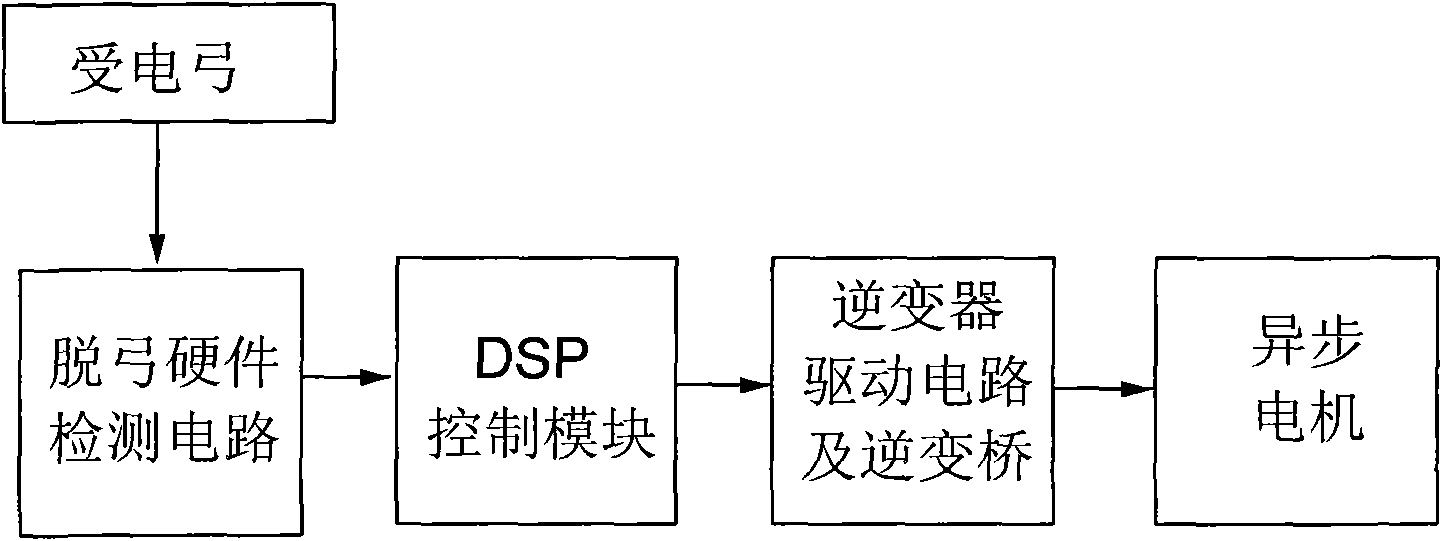

[0021] An inverter control system for a trolley-type power supply locomotive, such as figure 1 As shown, it consists of a pantograph, a bow-off hardware detection circuit, a DSP control module, an inverter drive circuit, an inverter bridge, and an asynchronous motor connected in sequence. The voltage, off-bow hardware detection circuit is used to detect the grid voltage of the power grid and output the detection signal to the DSP control module. After processing the preset control program inside the DSP control module, the control signal is output to the inverter drive circuit and the inverter bridge to control the asynchronous motor work. In this embodiment, the DSP control module adopts TMS320LF2407A chip.

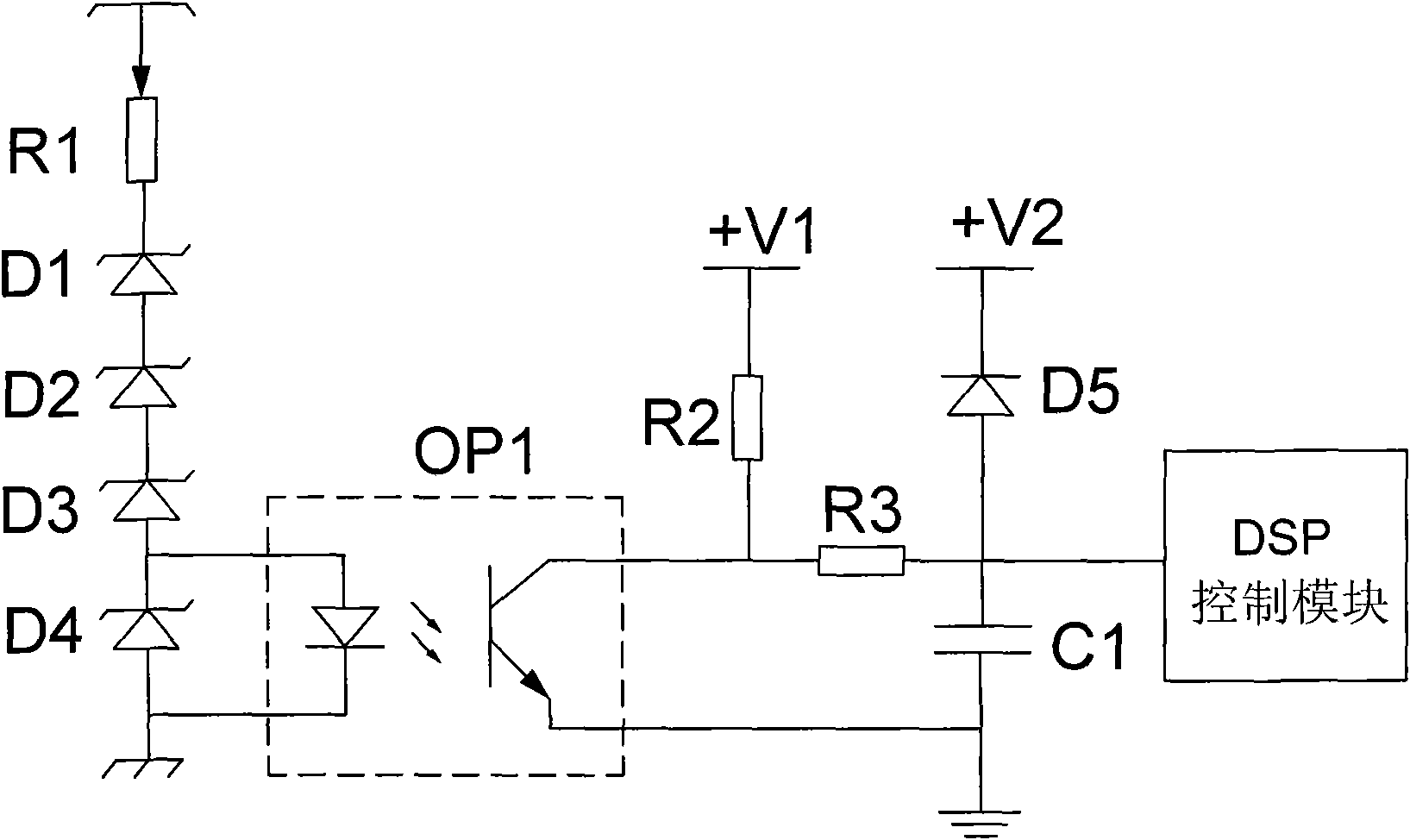

[0022] The specific structure of the off-bow hardware detection circuit is as follows: figure 2 As shown, the input side of the bow-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com