Coal mine underground explosion proof rubber tire transport trolley

An explosion-proof, transport vehicle technology, applied in the direction of goods transport vehicles, transport objects, transportation and packaging, etc., can solve the problems of coal mining operations, difficult safe transportation, low efficiency, and frequent transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

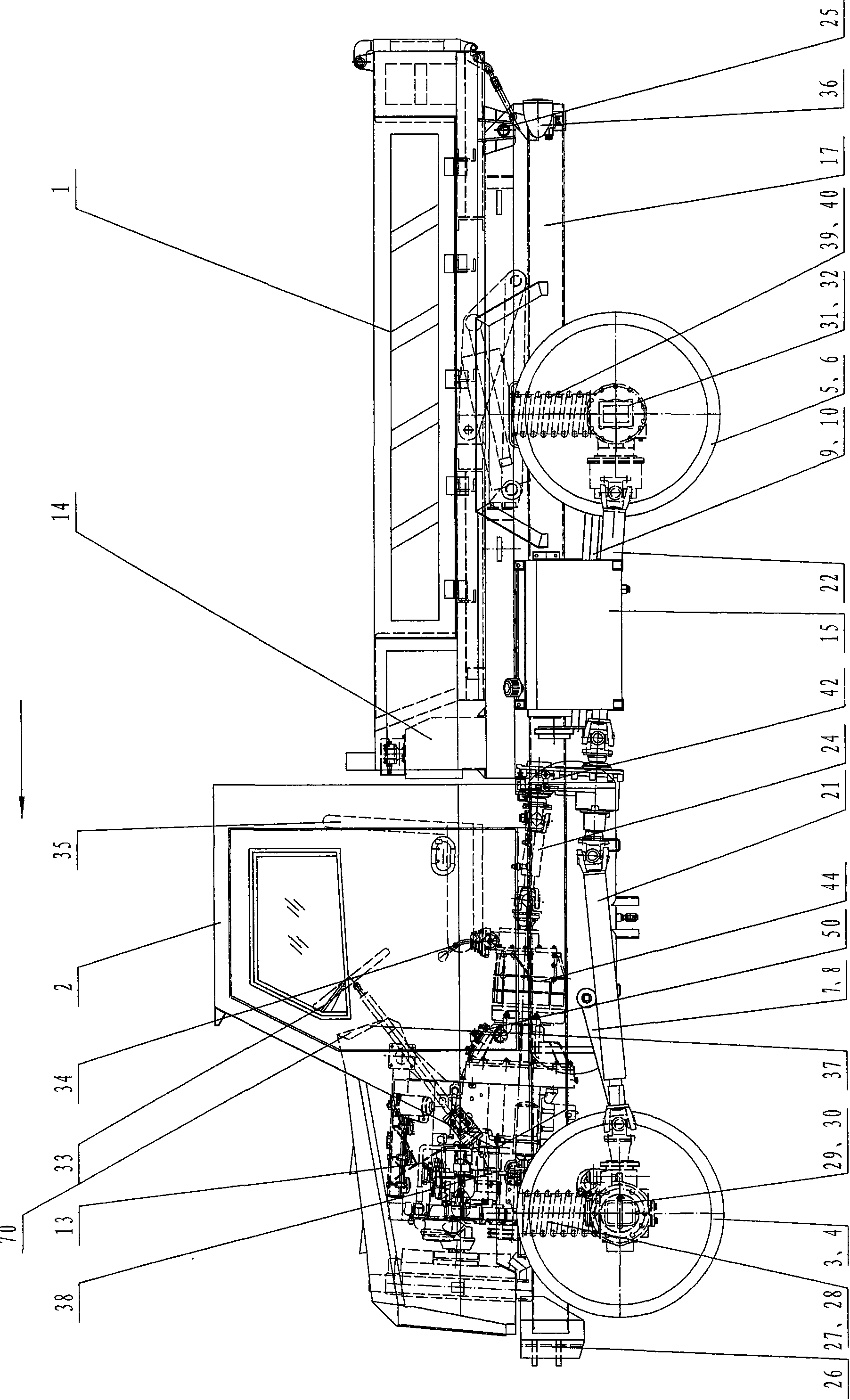

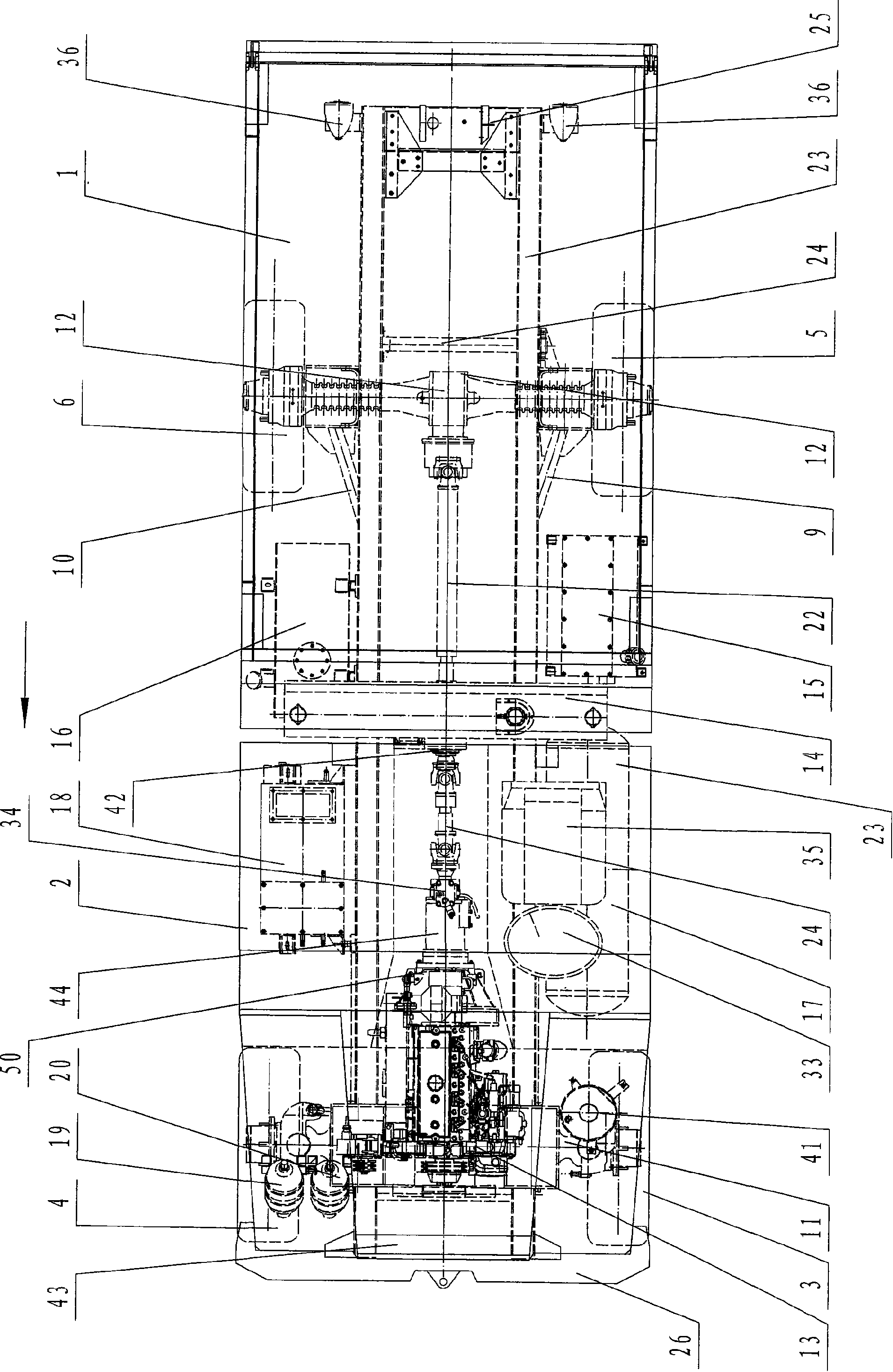

[0036] figure 1 , 2 Shown is the overall structure diagram, and the connection relationship of each component must be in the correct position and installed firmly.

[0037] Vehicle frame 17 is integral structure, diesel engine, driver's cab, dump car, hydraulic oil tank, fuel tank, gas tank, exhaust gas treatment box, replenishing water tank etc. are installed in the upper part, and transfer case, front and rear drive axles, front wheels, rear wheel, front and rear wheel spring suspension, etc.

[0038] The front and rear wheels are made of rubber wheels, which have good strength and corrosion resistance. They can be started at different times or at the same time. The front wheels are steered and have a small turning radius.

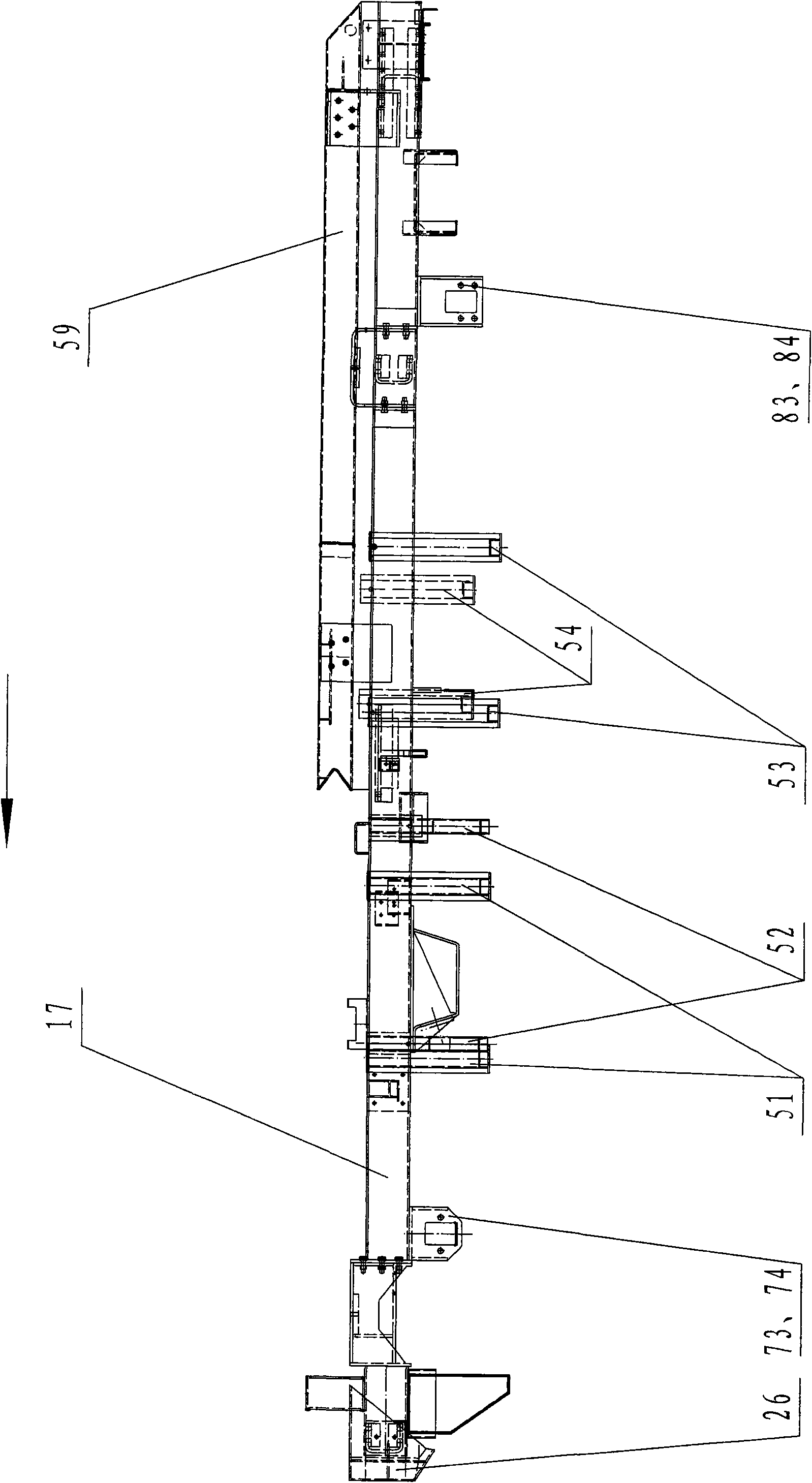

[0039] image 3 , 4 Shown is the structural diagram of the frame 17, which is a welded structure as a whole. It must be made of alloy structural...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap