Sealing-in method of metallic titanium and glass terminal post

A metal titanium and glass encapsulation technology, which is applied in the field of metal titanium and titanium alloys and glass sealing, can solve problems such as hidden quality problems, oxidation of the cover shell and central pole, edge defects of glass and cover sealing, etc. To achieve the effect of reliable quality, meeting work requirements and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this example, the size of the sealing hole is Φ6mm, the thickness of the sealing hole is 2mm, and the pole is 4J29 Kovar wire with Φ2mm.

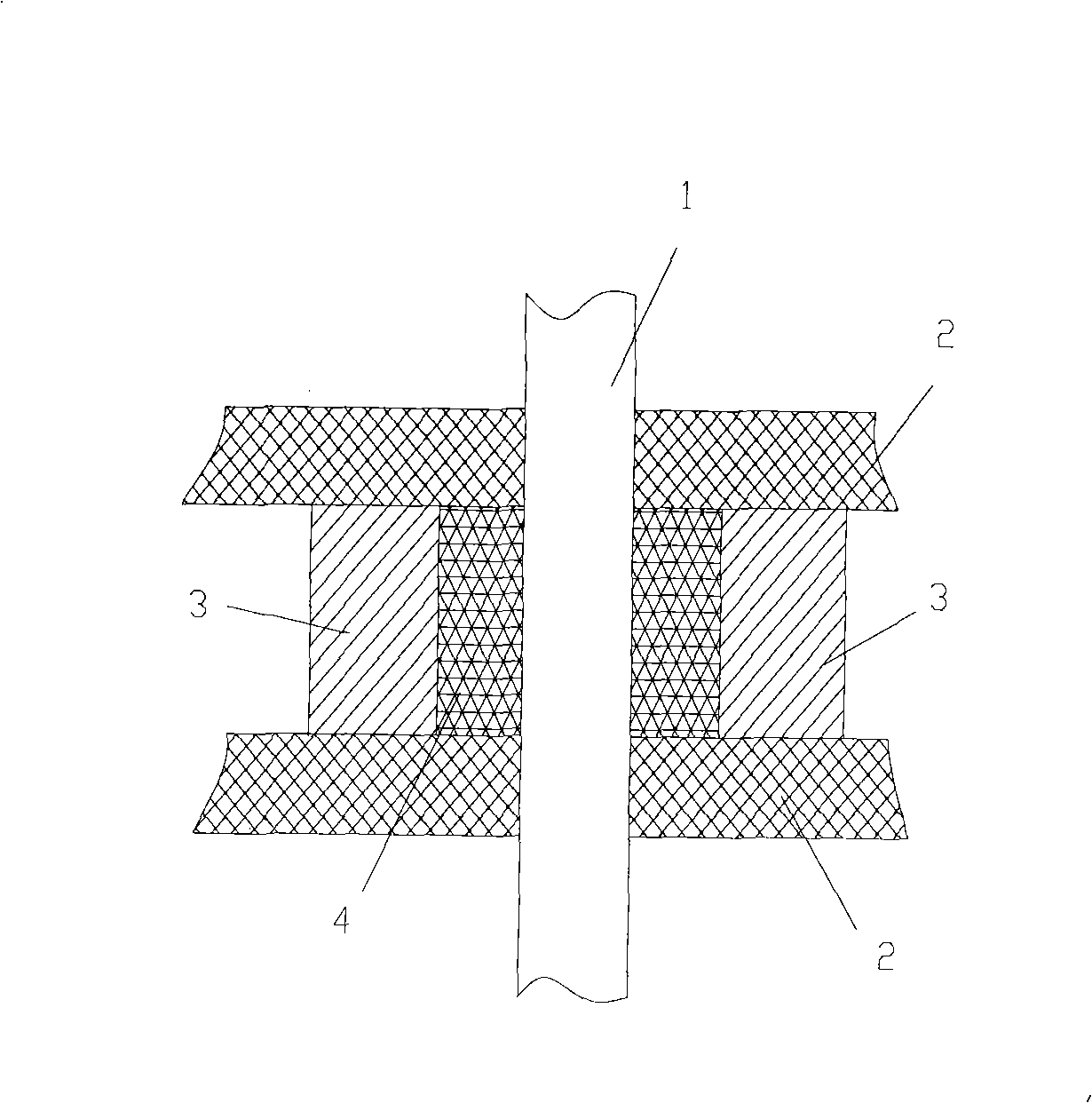

[0018] ①Start the experiment, put the pole 1, graphite mold 2, metal titanium shell 3, glass beads 4 and other parts such as figure 1 As shown in the assembly, fasten the mold;

[0019] ②Put the fastened mold into the vacuum furnace, seal the vacuum furnace, and wash the furnace twice with argon with a purity of 99.99%;

[0020] ③Pull a vacuum in the furnace, the vacuum degree is 6.0×10 -3 Pa;

[0021] ④Fill with argon with a purity of 99.99% to make the pressure in the furnace 0.9 standard atmosphere;

[0022] ⑤ Carry out the heating operation, starting from room temperature at a rate of 300°C / h, after holding at 150°C for 30 minutes, continue heating at a heating rate of 300°C / h, reaching 1020°C for 40 minutes;

[0023] ⑥ Cooling treatment, starting from 1000°C at a rate of 60°C / h, and continuing to cool to 200°C, and then at a rate...

Embodiment 2

[0025] In this example, the size of the sealing hole is Φ6.5mm, the thickness of the sealing hole is 3mm, and the pole is 4J29 Kovar wire of Φ3mm.

[0026] ①Start the experiment, put the pole 1, graphite mold 2, metal titanium shell 3, glass beads 4 and other parts such as figure 1 As shown in the assembly, fasten the mold;

[0027] ②Put the fastened mold into the vacuum furnace, seal the vacuum furnace, and wash the furnace twice with argon with a purity of 99.99%;

[0028] ③Pull a vacuum in the furnace, the vacuum degree is 6.0×10 -3 Pa;

[0029] ④Fill with argon with a purity of 99.99% to make the pressure in the furnace 0.85 standard atmospheres;

[0030] ⑤ Carry out the heating operation, starting from room temperature at a rate of 300°C / h, holding at 160°C for 30 minutes, and continuing to raise the temperature at a heating rate of 300°C / h, reaching 1000°C for 45 minutes;

[0031] ⑥ The temperature is lowered at a rate of 50°C / h, starting from 1000°C, and continuing to lower...

Embodiment 3

[0033] In this example, the size of the sealing hole is Φ6mm, the thickness of the sealing hole is 5mm, and the pole is 4J29 Kovar wire with Φ2mm.

[0034] ① Put the poles into the holes of the upper and lower graphite templates of the graphite mold, add the glass beads and the metal titanium shell into the mold, and fasten the mold;

[0035] ② Put the fastened mold into a vacuum furnace, seal the vacuum furnace, and wash the furnace twice with 99.99% argon;

[0036] ③Pull a vacuum in the furnace, the vacuum degree is 6.0×10 -3 Pa;

[0037] ④Fill in argon with a purity of 99.99% to make the pressure in the furnace 0.87 standard atmospheres;

[0038] ⑤ Carry out the heating operation, starting from room temperature at a rate of 300°C / h, holding at 155°C for 30 minutes, and continuing to raise the temperature at a heating rate of 300°C / h, reaching 1010°C for 42 minutes;

[0039] ⑥ The temperature is lowered at a rate of 55°C / h, starting from 1000°C, the temperature is continuously l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com