Fermentation process adopting material outside circulation and equipment thereof

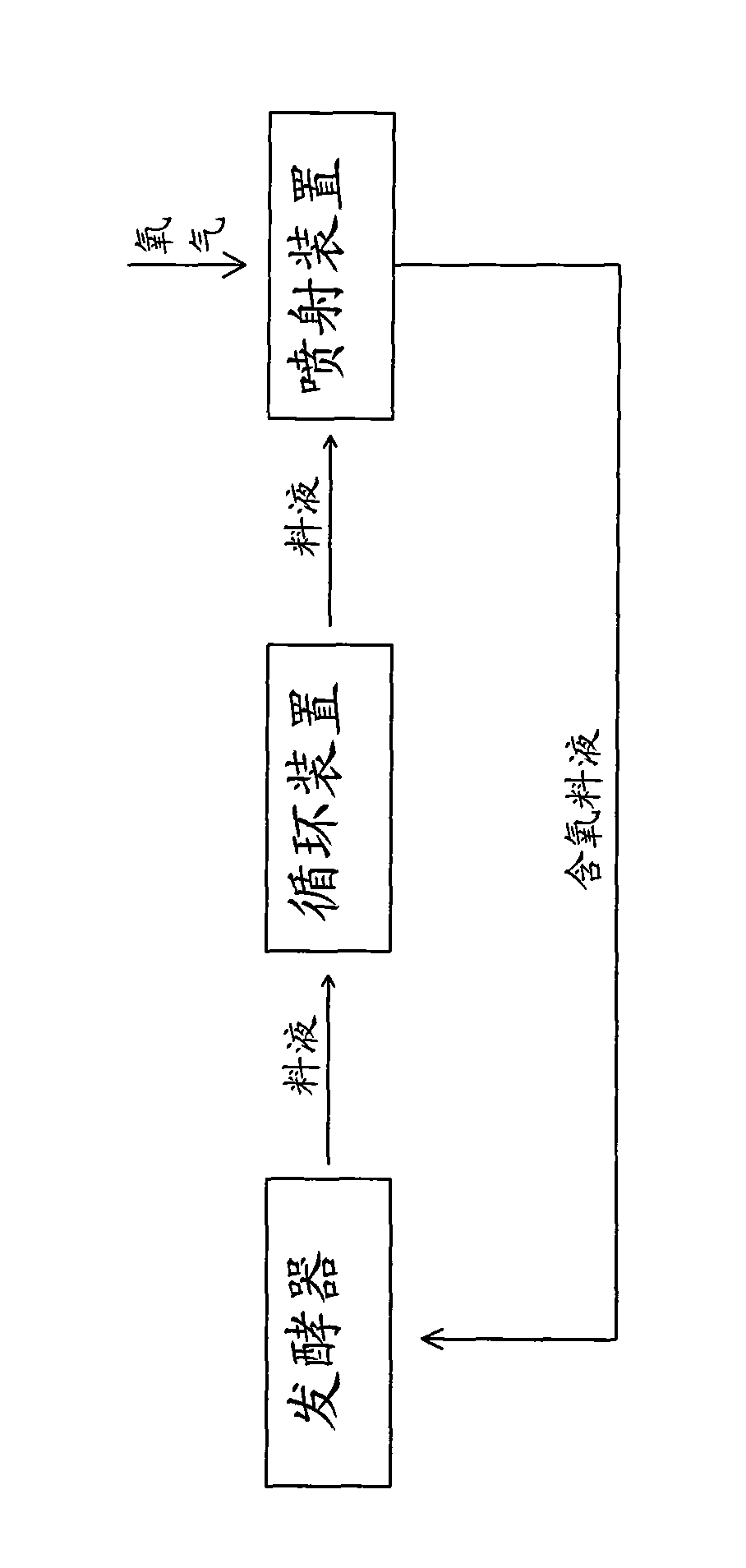

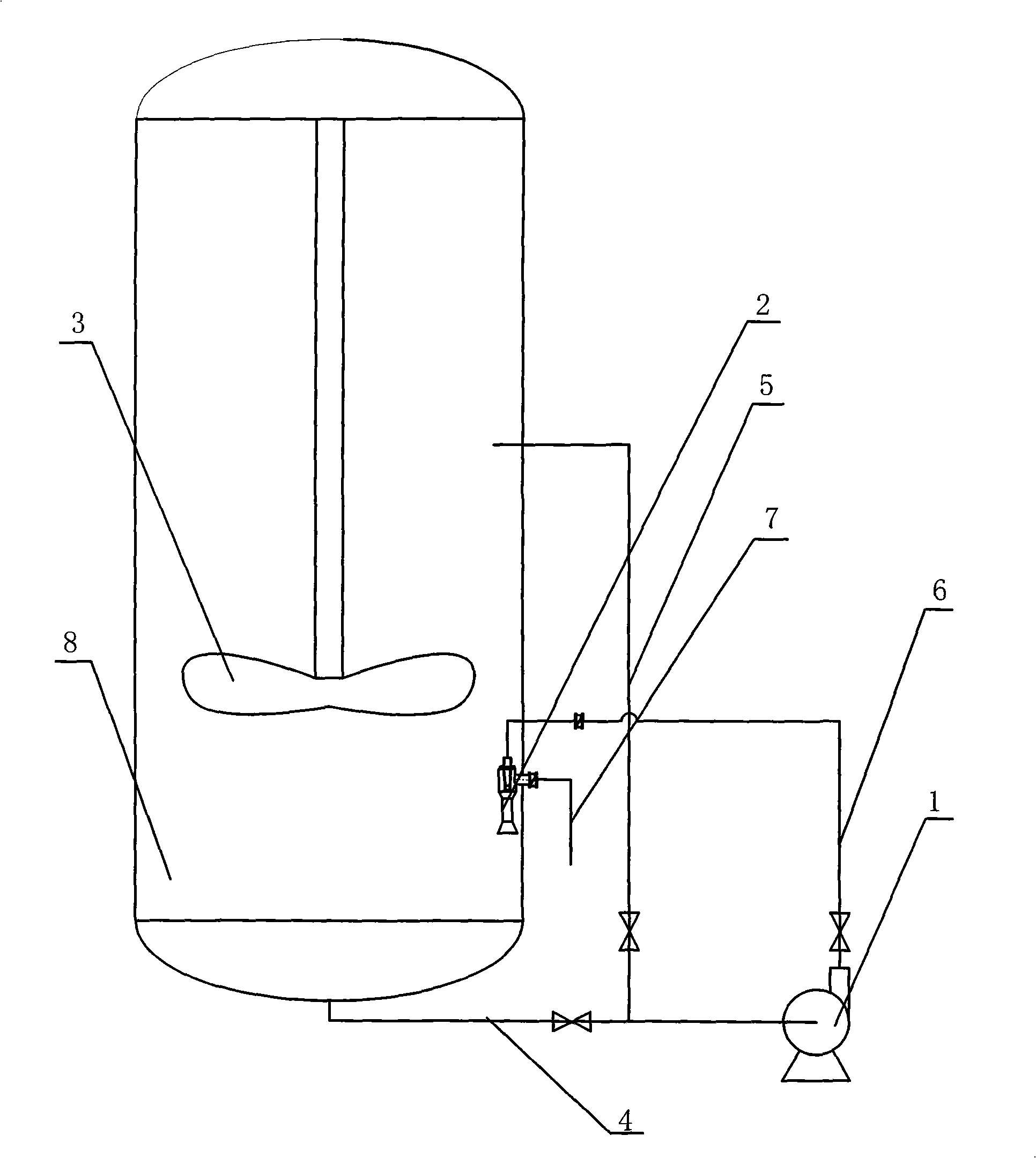

A technology of fermentation process and fermentation equipment, which is applied in the field of fermentation process, can solve the problems of poor mixing effect of air and materials, inability to form jets in nozzles, and inconspicuous fermentation effect, so as to shorten the fermentation cycle, ensure sealing and independence, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] at 500m 3 Put the material in the fermentation tank to 90% of the total volume, heat the material to 100°C to sterilize for 30 minutes, cool down to 20°C-40°C, inoculate the fermentation bacteria, ventilate, and then turn on the circulation pump to start fermentation and control the flow of the circulation pump 2500m 3 / h-4000m 3 / h, the amount of air sucked by the injector is from 1000m 3 / h-4000m 3 / h adjustment, the air pressure is 0.2MPa-0.35MPa, and the feed liquid mixed with air by the injector is sent back to the fermenter by the injector.

[0019] After adopting this fermentation process, the amount of dissolved oxygen in fermentation is 4 times that of the original fermentation process, the fermentation cycle is reduced by 10 hours, and the power consumption is 40% lower than that of traditional fermentation tanks.

Embodiment 2

[0021] at 50m 3 Put the material in the fermentation tank to 75% of the total volume, heat the material to 110°C to sterilize for 60 minutes, cool down to 30°C-50°C, inoculate the fermentation bacteria, ventilate, and then turn on the circulation pump to start fermentation and control the flow of the circulation pump 250m 3 / h-500m 3 / h, the amount of air inhaled by the injector is from 200m 3 / h-400m 3 / h adjustment, the air pressure is 0.2MPa-0.50MPa, and the feed liquid mixed with air by the injector is sent back to the fermenter by the injector.

[0022] After adopting this process, the amount of dissolved oxygen in fermentation is 2.5 times that of the original fermentation process, the fermentation cycle is reduced by 3 hours compared with the same period last year, and the power consumption is reduced by 25% compared with traditional fermentation tanks.

Embodiment 3

[0024]at 1000m 3 Put the material in the fermentation tank to 80% of the total volume, heat the material to 70°C to sterilize for 40 minutes, cool down to 35°C-50°C, inoculate the fermentation bacteria, ventilate, and then turn on the circulation pump to start fermentation and control the flow of the circulation pump 5000m 3 / h-8000m 3 / h, the amount of air inhaled by the ejector is from 4000m 3 / h-7500m 3 / h adjustment, the air pressure is 0.35MPa-0.45MPa, and the feed liquid mixed with air by the injector is sent back to the fermenter by the injector.

[0025] After adopting this process, the amount of dissolved oxygen in fermentation is 5 times that of the original fermentation process, the fermentation cycle is reduced by 8 hours compared with the same period last year, and the power consumption is reduced by 55% compared with the traditional fermentation tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com