Construction method for preset nut type steel-reinforced concrete compound pier template fixing device

A formwork fixing and construction method technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., to achieve the effects of convenient on-site construction operations, low cost, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

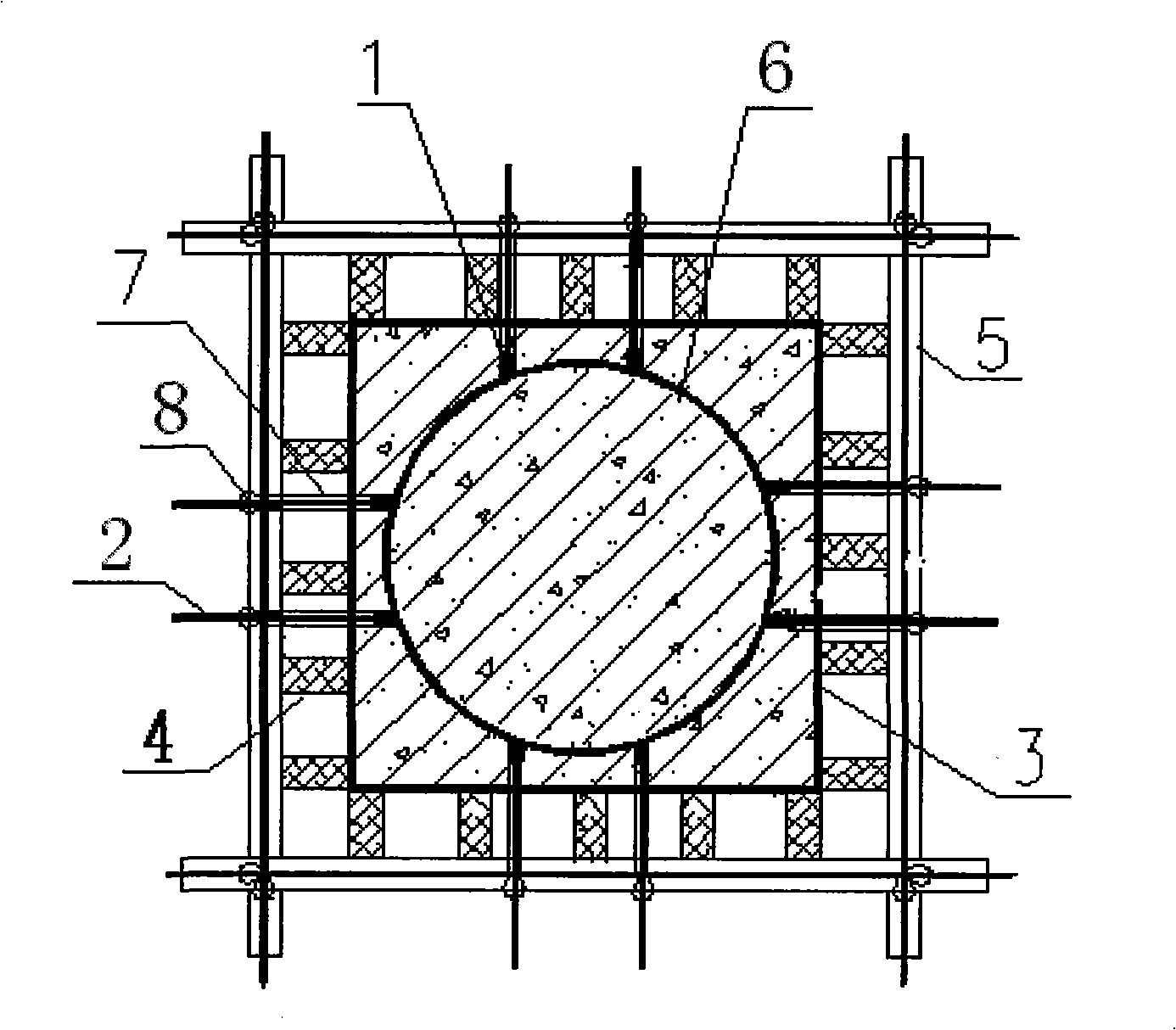

[0060] The pre-installed nut type steel concrete composite column formwork fixing device in this example is used for the steel column as a round steel pipe, such as figure 1 As shown, the specific construction steps during construction are:

[0061] 1. The shaped steel column 6 is made of round steel pipe, and the nut 1 is made of an elongated nut. Position the nut 1 on the round steel pipe column and set out the wire. Welding personnel weld the nut in the direction of the column axis. The weld seam height is 4mm, and the position error is controlled within 3mm. . The gap between the nut 1 and the steel pipe wall is relatively large, and the welding seam height is 4mm.

[0062] 2. Before installing the formwork, screw the screw 2 into the nut 1 with a wrench, put the PVC pipe 7 on the screw 2, and adjust the direction.

[0063] 3. Determine the opening position of the formwork according to the position diagram of the steel pipe column nut, draw the opening diagram of the fo...

Embodiment 2

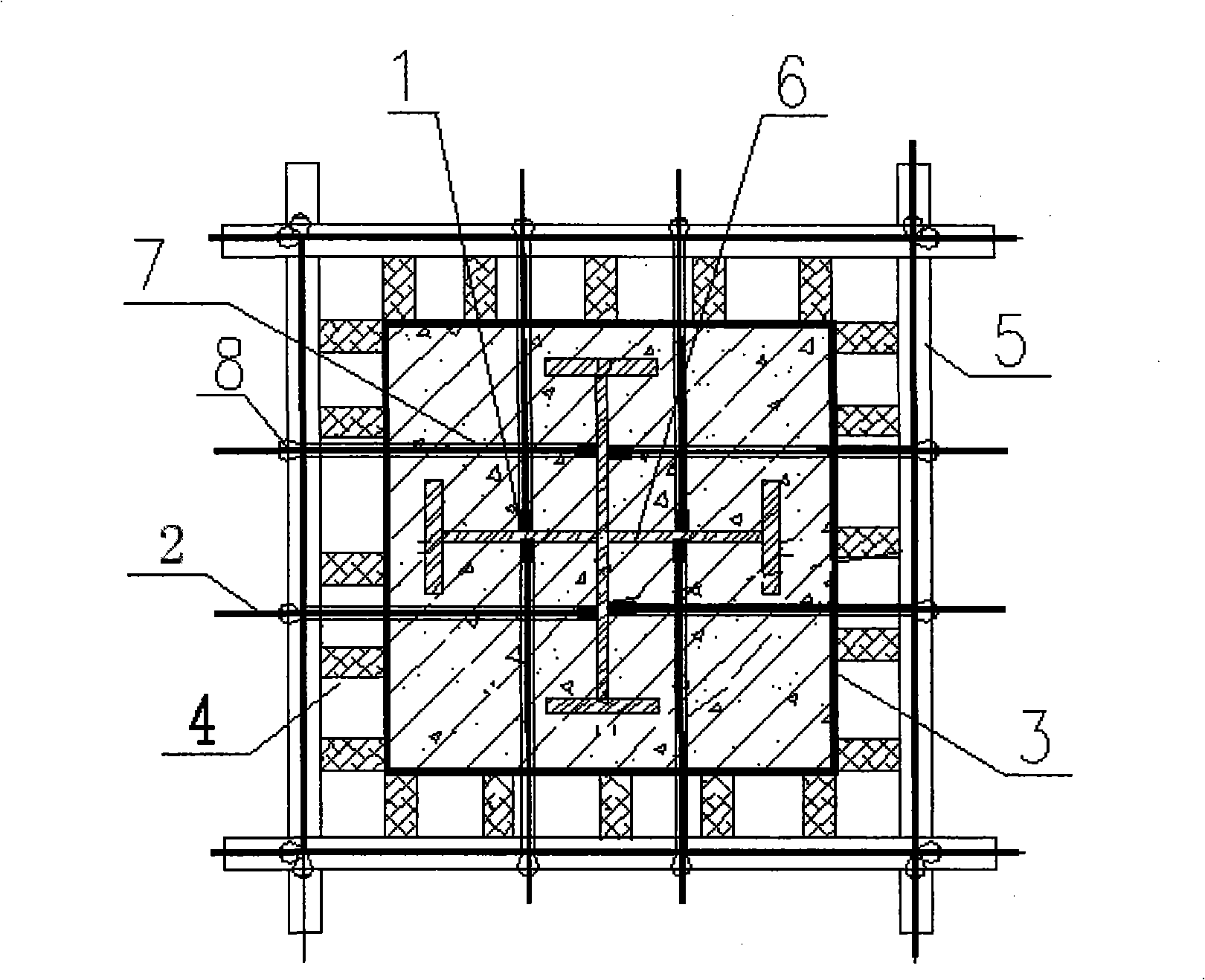

[0067] The pre-installed nut type steel column concrete composite column template fixing device of this embodiment is used for H-shaped and cross-shaped steel columns, such as figure 2 As shown, the basic structure is the same as that of Example 1, the difference is that the preset nut 1 is pre-welded on the 6-column web of the steel column, and the screw 2 is screwed into the nut 1 with a wrench before the formwork is installed, and the screw 2 is covered with PVC Pipe 7, install column formwork 3, inner keel wooden side 4, outer keel double steel pipe 5 successively again.

[0068] Except above-mentioned embodiment, the present invention also can be the concrete combination column formwork fixing of the shaped steel column of other structural forms, construction implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com