Man-made lawn raw material mixing device

A technology of mixing device and artificial turf, applied in the directions of mixers, mixing methods, mixers with rotating mixing devices, etc., can solve the problems of poor local performance, single raw material, long mixing time, etc., to reduce surface friction and prolong use. The effect of low life and maintenance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

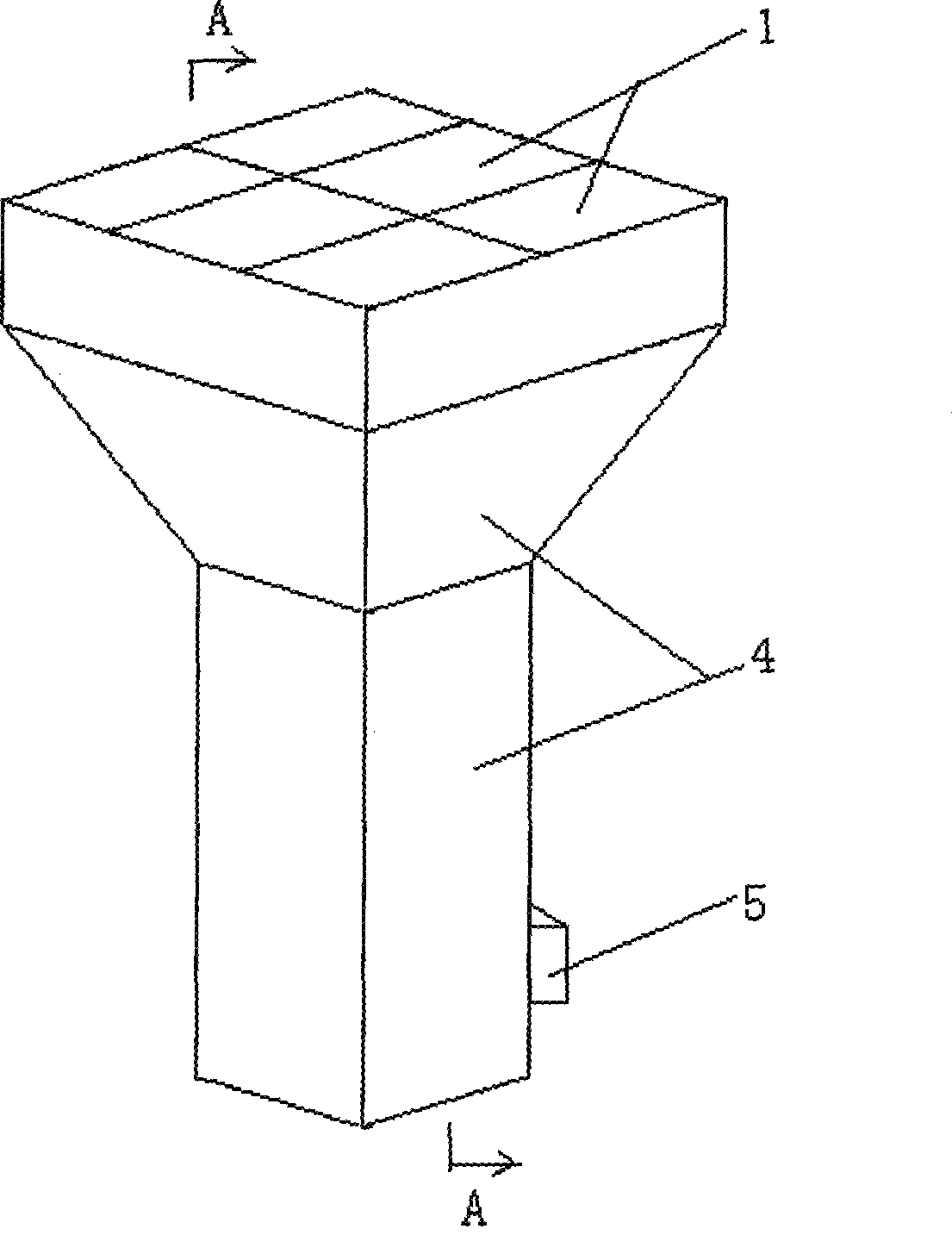

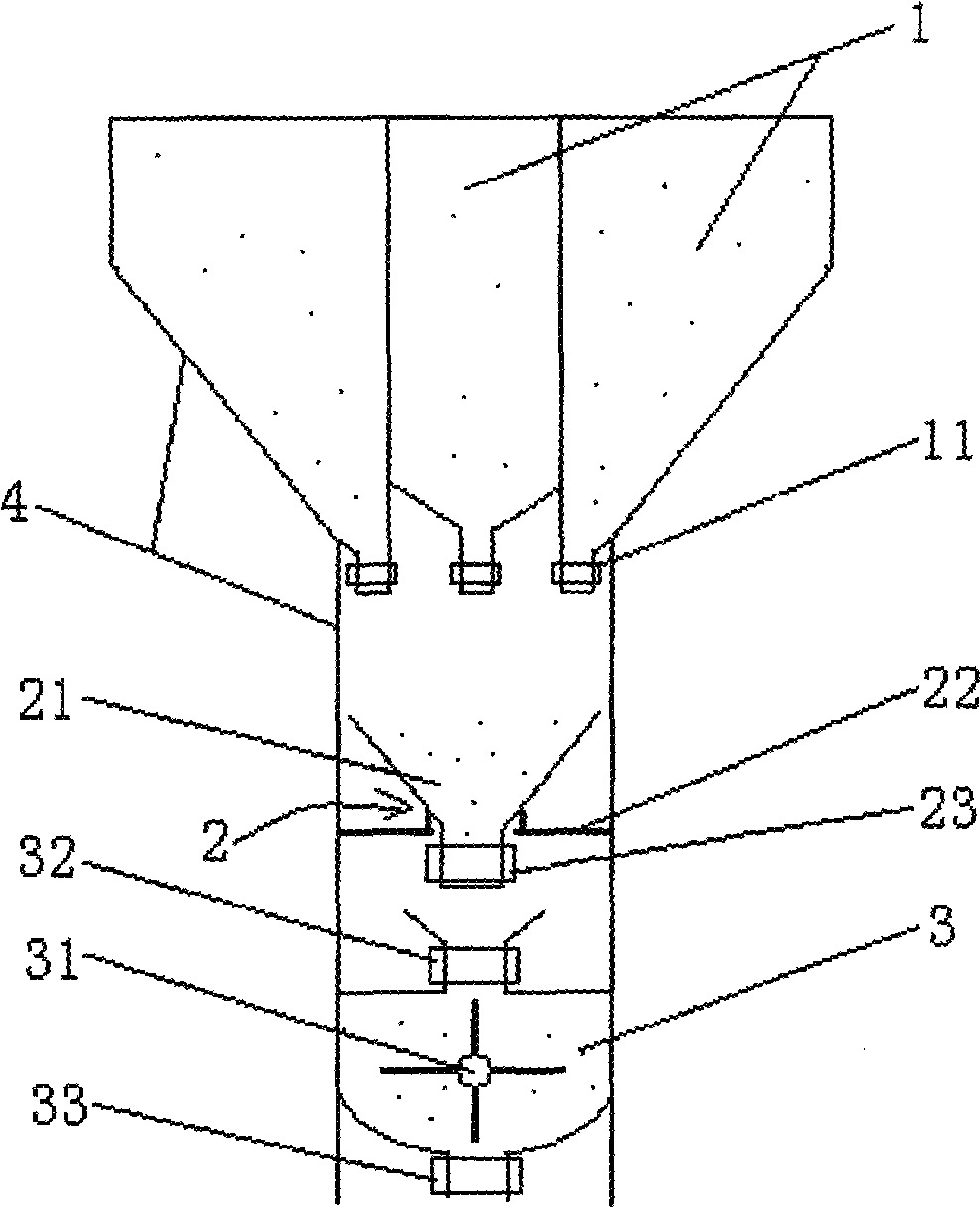

[0022] Such as figure 1 , 2 As shown, the present invention includes a weighing device 2, a raw material mixer 3, and six storage bins 1. The discharge port of the storage bin 1 is located above the feed port of the weighing device 2, the discharge port of the weighing device 2 is located above the feed port of the raw material mixer 3, and the discharge port of the storage bin 1 and the weighing device 2 Pneumatic valves 11 and 23 are respectively provided at the feed ports, and pneumatic valves 32 and 33 are respectively provided at the feed port and the discharge port of the raw material mixer 3 . The storage bin 1 , the weighing device 2 , and the raw material mixer 3 are sequentially arranged in the casing 4 .

[0023] Such as figure 2 As shown, the weighing device 2 is composed of a weighing hopper 21 and an electronic scale 22, the base of the electronic scale 22 is fixedly connected to the housing 4, the weighing hopper 21 is arranged on the electronic scale 22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com