System for producing strong ammonia water by absorbing ammonia in air

A gas absorption and absorption system technology, applied in the field of deamination and reuse of chemical gas, can solve the problems of limited ammonium sulfate market capacity, difficulty in selling ammonium sulfate, large consumption of sulfuric acid, etc., to meet the requirements of production and environmental protection, desorption regeneration solution The effect of small amount and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

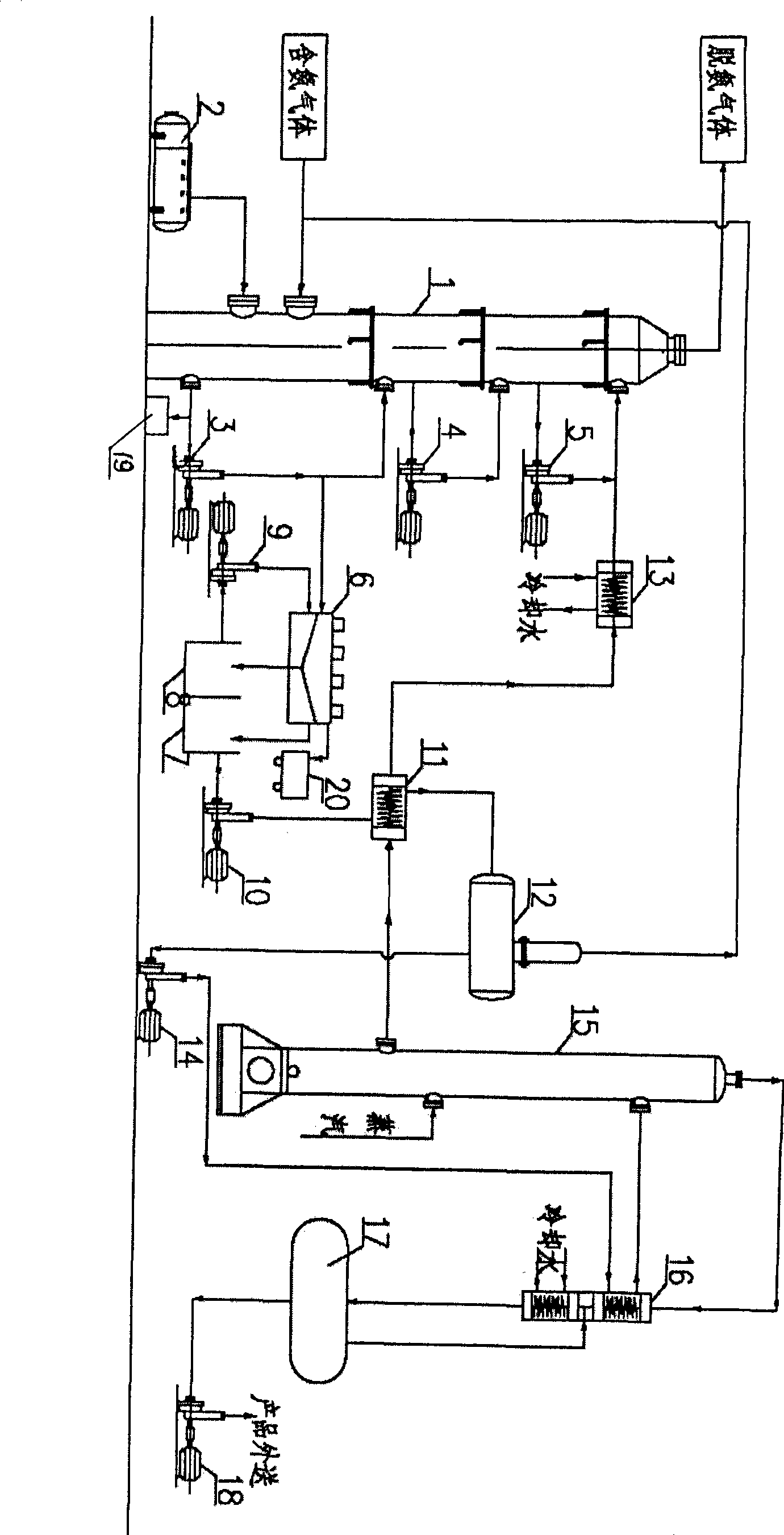

[0027] A preferred embodiment of a system for producing concentrated ammonia water for absorbing ammonia in gas according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Referring to accompanying drawing, the system for producing concentrated ammonia water by absorbing ammonia in gas of the present invention consists of an absorption system for absorbing ammonia in gas and a desorption system for producing concentrated ammonia water.

[0029] The absorption system is an absorption tower 1 with a three-stage circulating spraying unit. The top of the absorption tower 1 is provided with an ammonia-removing gas outlet, and the lower part of the absorption tower 1 is provided with an ammonia-containing gas inlet. The three-stage circulation spraying units are arranged on the absorption tower 1 in sections according to different heights. Each circulating spraying unit is composed of a spraying device, a liquid break...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap