Ultrasonic humidifier

A humidifier and ultrasonic technology, applied in ultrasonic humidifiers, air humidification systems, heating methods, etc., can solve the problems of unstable working state of the transducer, narrow application area of the humidifier, and increased energy consumption of the humidifier. The effect of preventing water mist from entering the inside of the fan, reducing backflow water and water mist, and improving the atomization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

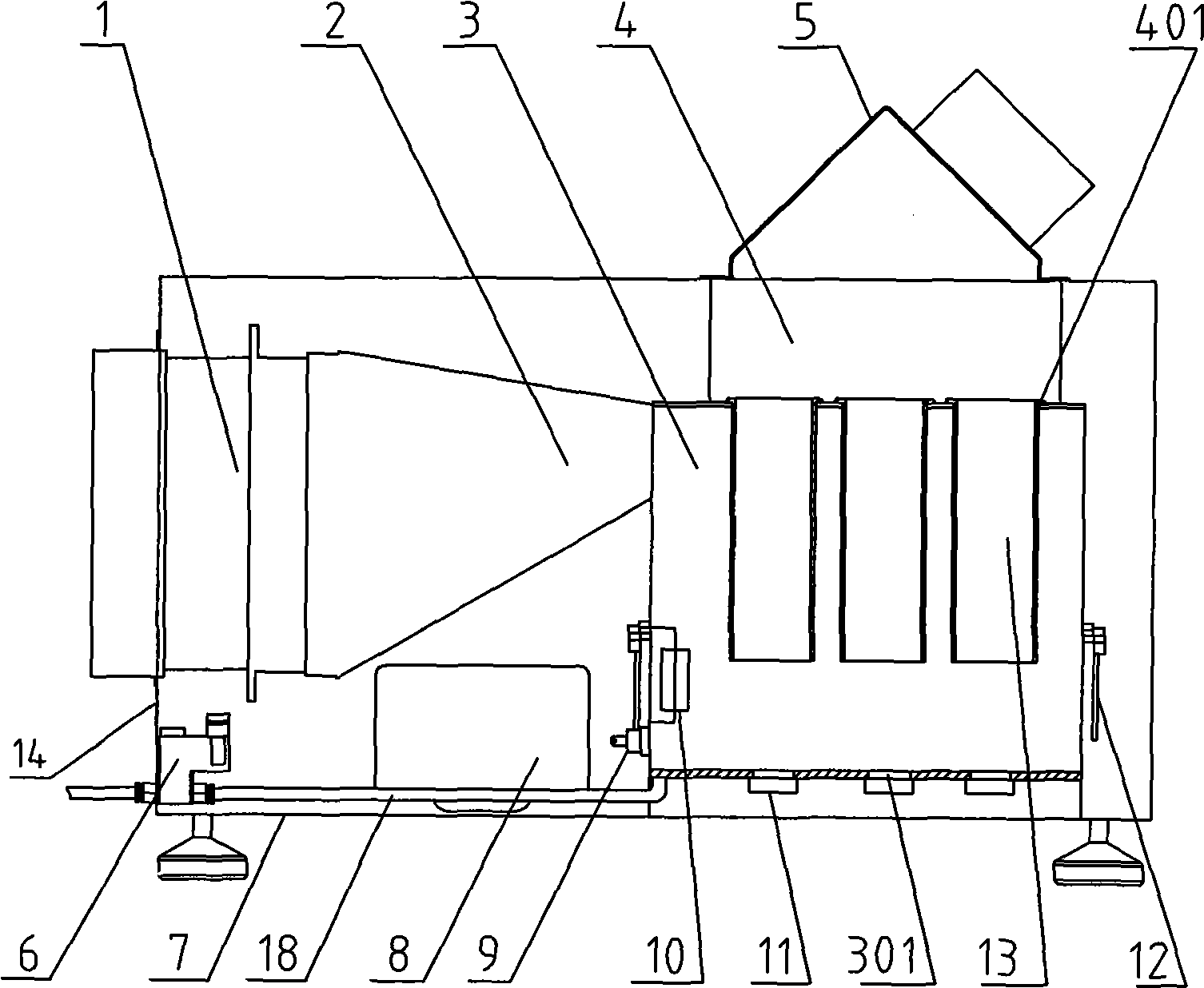

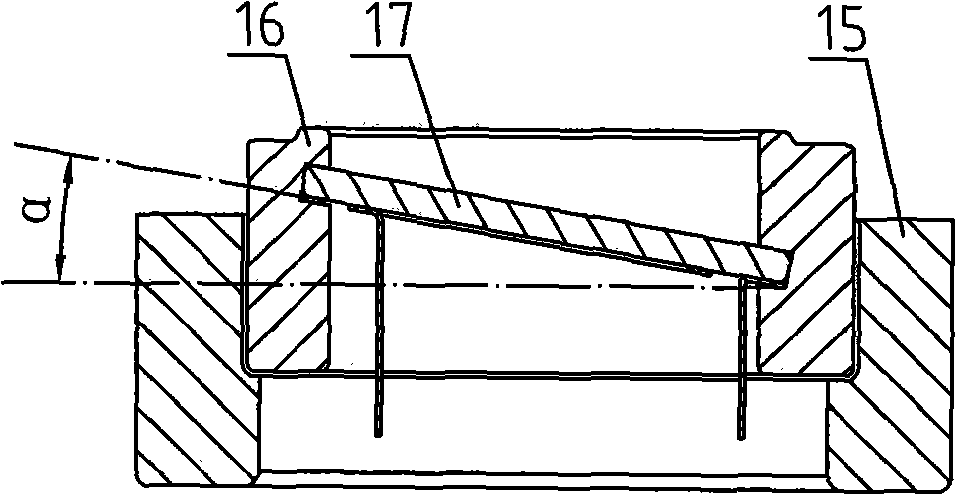

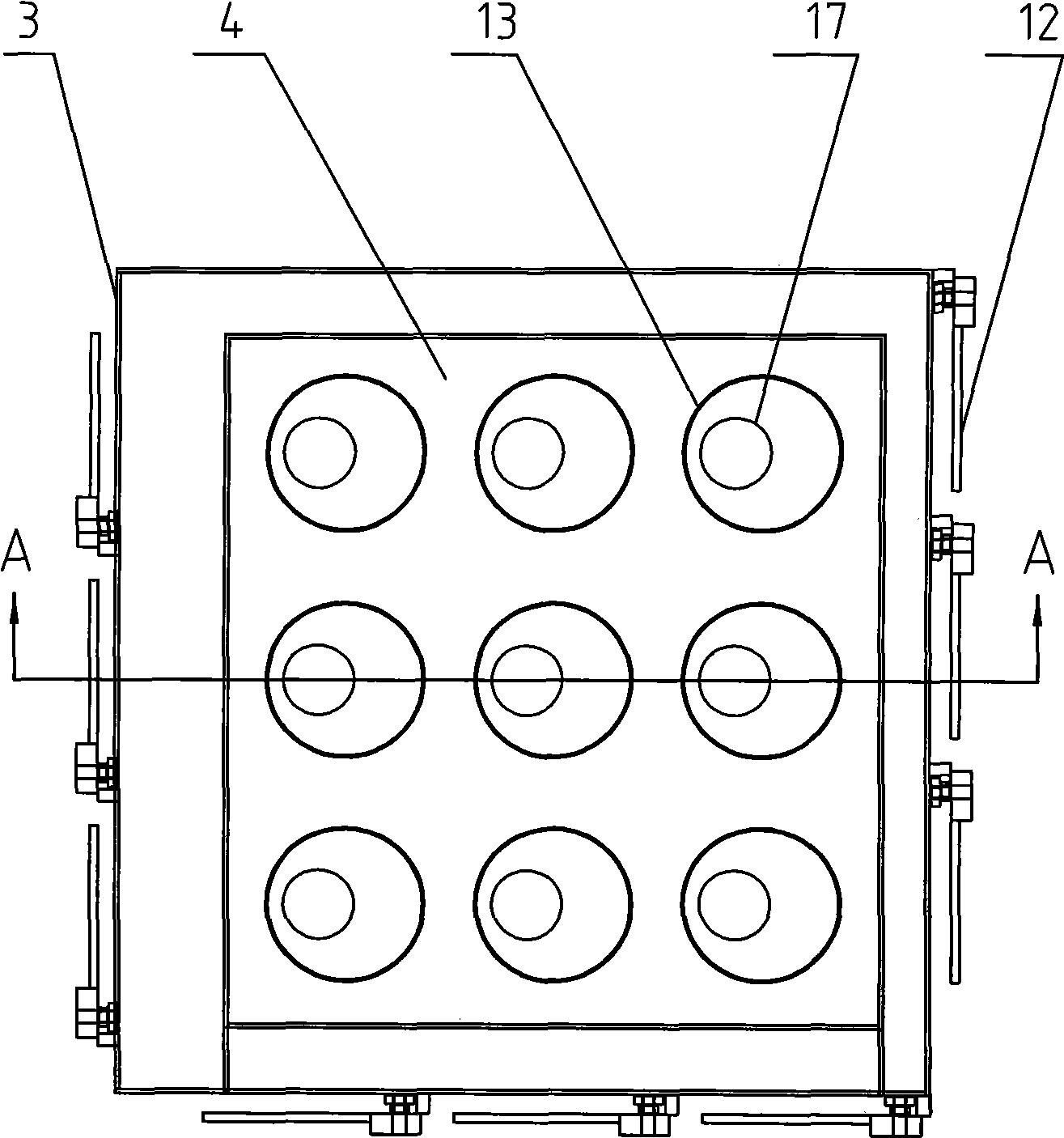

[0024] see figure 1 — Figure 4 , the ultrasonic humidifier in this embodiment includes a fan 1, a water tank 3, a mist outlet 5, a frame 7, a transformer 8, a temperature switch 9, a water inlet device and a mist outlet device, wherein the water inlet device includes a solenoid valve 6, a water inlet pipe 18 and a liquid level switch 10, the mist outlet device includes a mist outlet guide plate 4, a mist outlet guide pipe 13, a transducing device 11 and a drive plate 12, wherein the number of the mist outlet guide tube 13, the transduction device 11 and the drive board 12 is equal , that is, one mist-out guide tube 13 corresponds to one energy-transforming device 11 and one drive plate 12 respectively. In the present invention, the number of mist-out guide tubes 13 can be set according to the actual situation. The energy-transducing device 11 in this embodiment is also It includes a fixed seat 15, a sealing ring 16 and a transducer sheet 17.

[0025] The blower fan 1, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com