Thick oil heating furnace

A heating furnace and heavy oil technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing operating costs of petrochemical enterprises, unfavorable energy consumption structure, etc., and achieve simple operation and maintenance of equipment, reduce Low production cost, convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

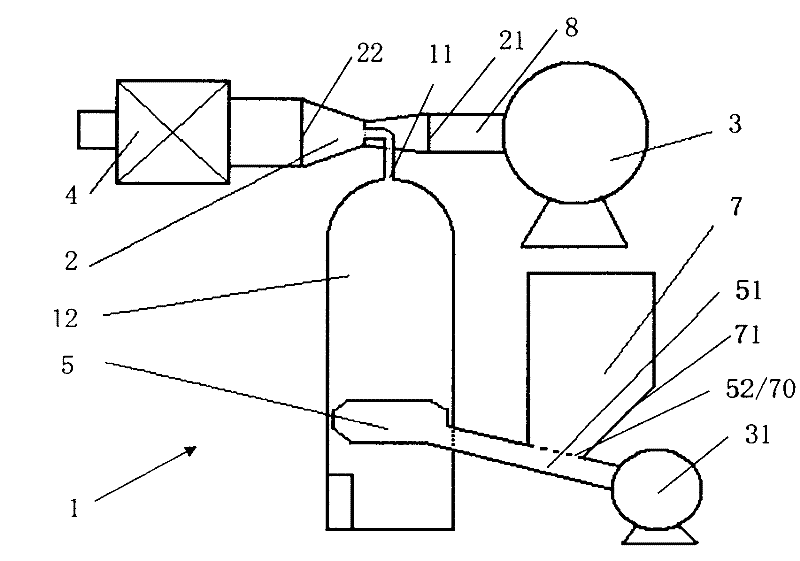

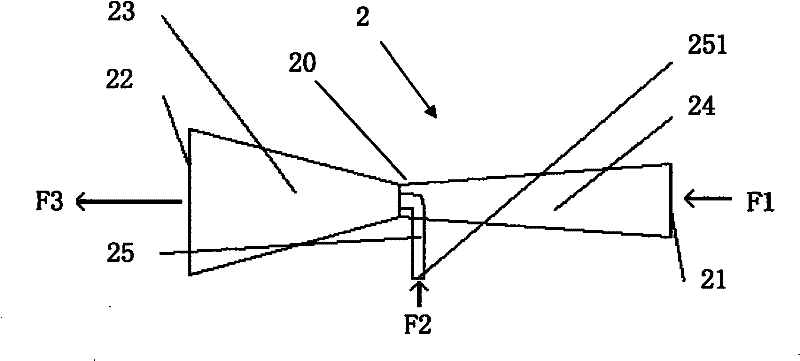

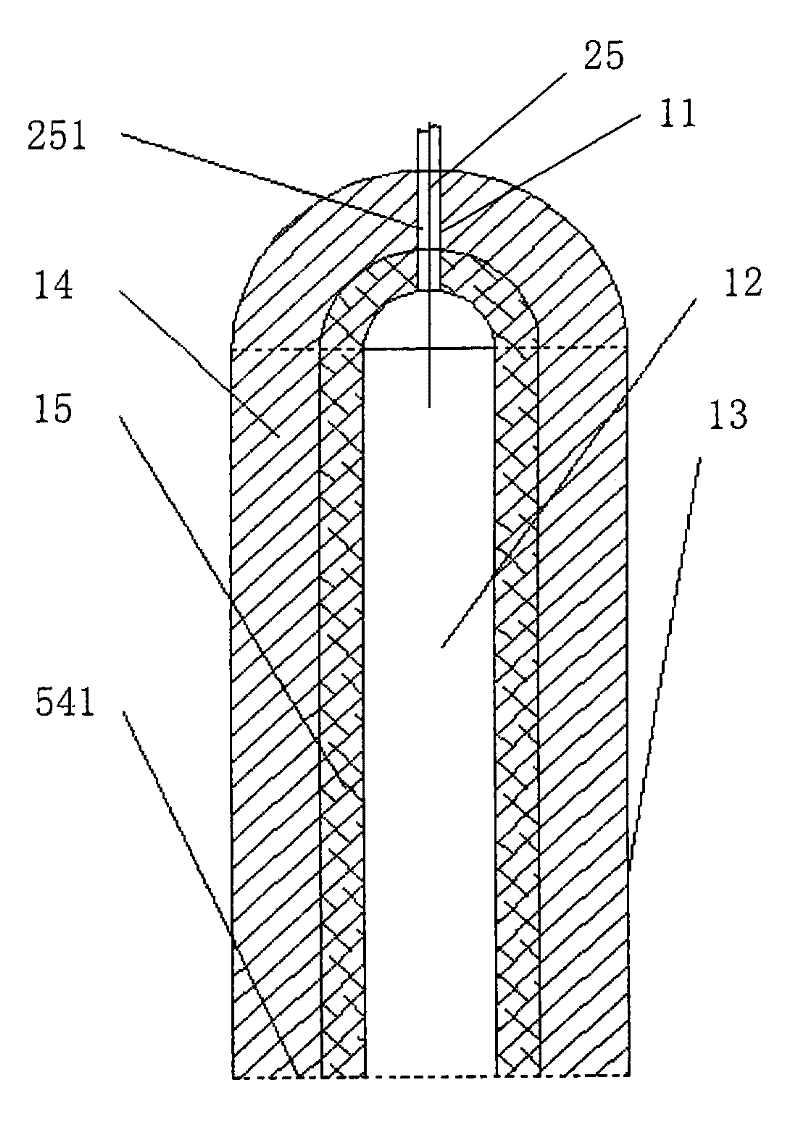

[0016] Such as figure 1 As shown, the present invention provides a kind of heavy oil heating furnace, comprises combustion stove 1, and combustion stove 1 is provided with smoke outlet 11, and smoke outlet 11 is connected with a Lafal spout thermostat 2, and Lafal The nozzle thermostat 2 is provided with an air inlet interface 21, a heating interface 22 and a throat 20 between the air inlet interface 21 and the heating interface 22. The air inlet interface 21 can be communicated with a blower 3 through a pipeline 8, and the heating interface 22 It communicates with a heating device 4 . Among them, it is preferable to make the blower 3 also communicate with the furnace 12 of the combustion furnace 1 . Thereby the fuel can be combusted with part of the air transported by the blower 3 in the furnace 12 of the fuel stove 1 to generate high-temperature hot flue gas, which enters the Rafael spout thermostat 2 after being discharged from the smoke outlet 11, and is combined with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com