Method for detecting oxygen content in butadiene by utilizing semiconductor laser technique

A laser technology and butadiene technology, applied in the field of detection, can solve the problems of inability to realize automation, long analysis cycle, low precision, etc., and achieve the effects of accurate and reliable analysis results, convenient automatic control, and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

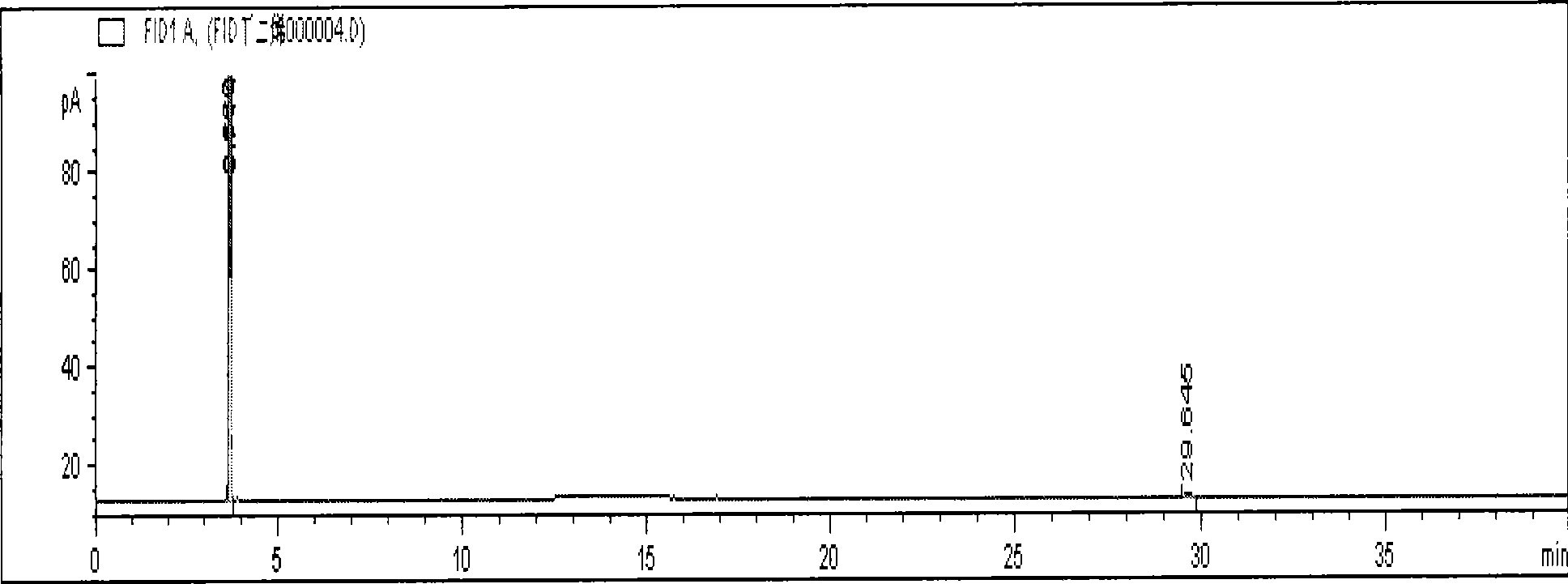

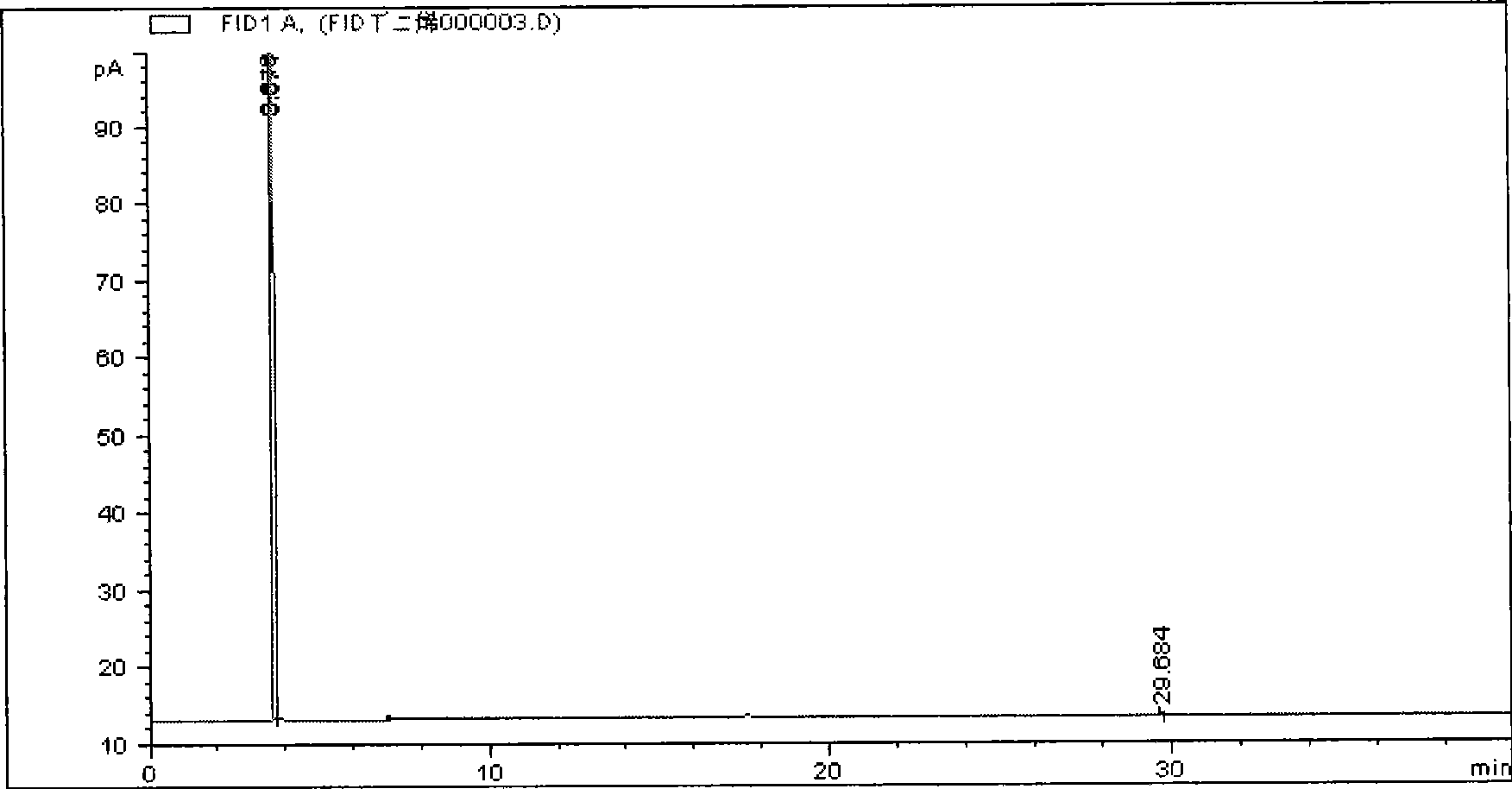

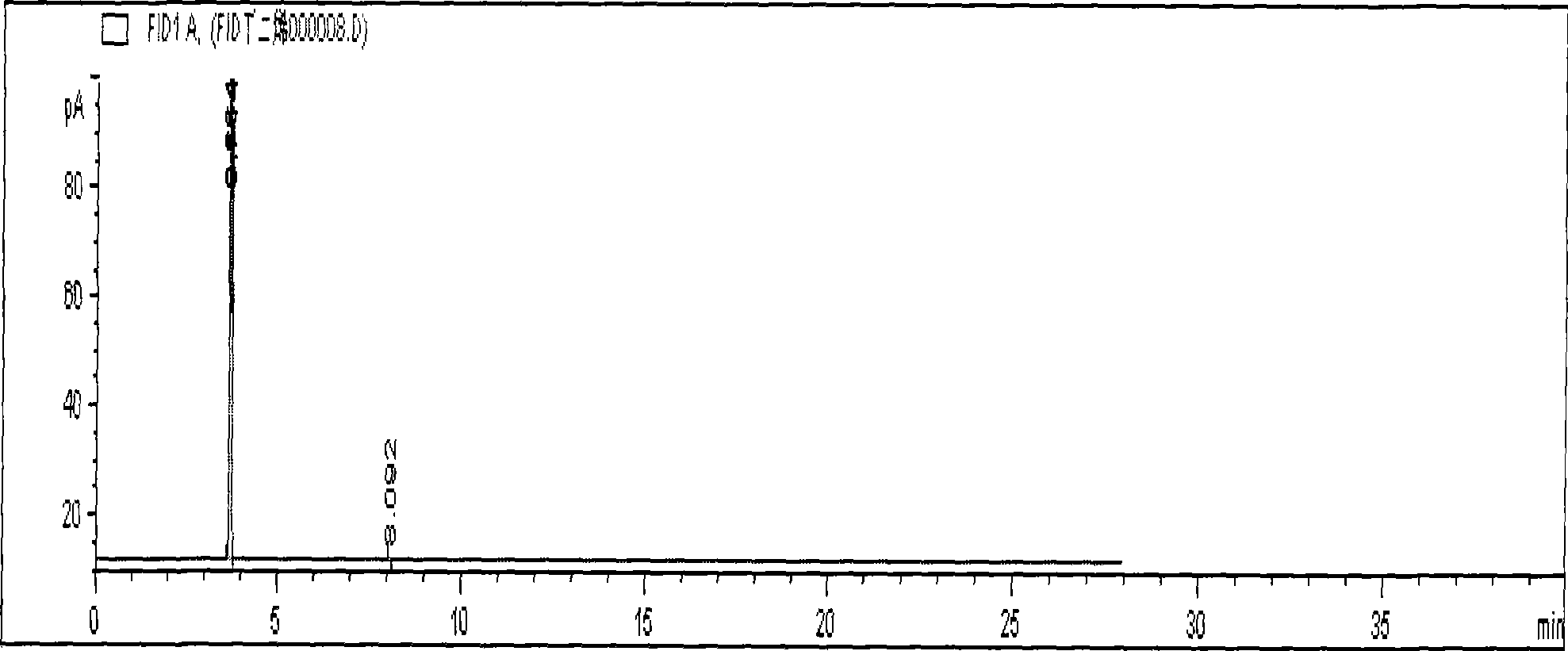

Image

Examples

Embodiment Construction

[0042] 1. Preparation before the experiment

[0043] First turn on the power of the LAG-4000 semiconductor laser instrument, and the instrument performs a self-test; after the instrument is running normally, perform a leak test on the bypass pipe and gas circuit to ensure that there is no leak in the gas circuit of the instrument analysis room. Then open the nitrogen valve and continuously feed high-purity nitrogen for 15 minutes to replace the analysis system to ensure that there is no oxygen in the analysis system.

[0044] 2. Sample analysis

[0045] Close the nitrogen valve and open the injection valve at the same time, so that the sample to be tested (industrial butadiene) enters the sample chamber of the analysis system. A laser beam with a wavelength of 760nm and an intensity of 1mW was emitted by a LAG-4000 semiconductor laser instrument to irradiate the sample. After measuring the irradiation, the oxygen content in the butadiene of the sample to be tested can be cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com