Self assembled monolayer for improving adhesion between copper and barrier layer

A technology of metal barrier layer and copper layer, applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problems of induced hole formation and barrier layer delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] [19] provides several embodiments for an improved metal integration technique that adds an adhesion promoting layer to enhance interfacial adhesion. It should be understood that the present invention can be implemented in various ways, including processes, methods, devices, or systems. Several embodiments of the invention are described below. It will be obvious to a person skilled in the art that the present invention may be practiced without all or some of the characteristic details described below.

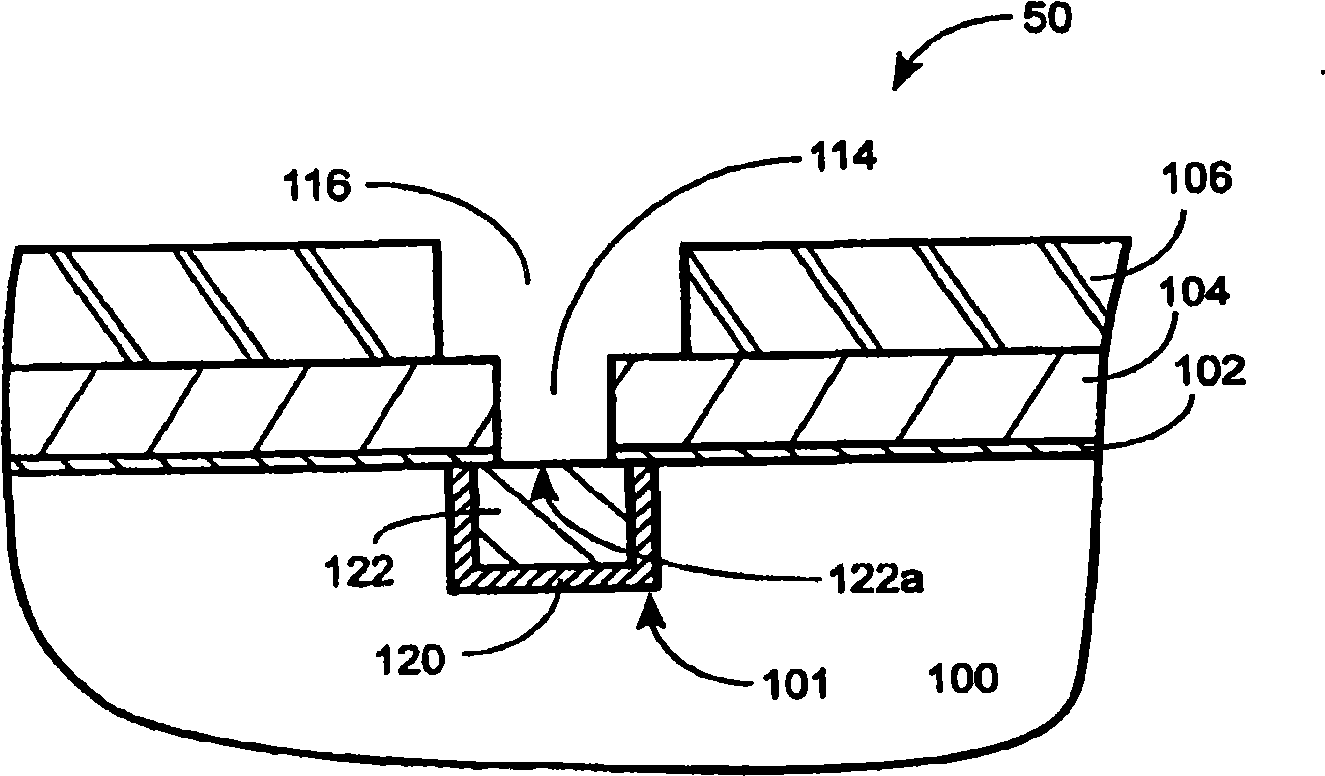

[0020] [20] Figure 1A Exemplary cross-sections of one or more interconnect structures are shown after being patterned using a dual damascene processing step. The interconnect structure is located on a substrate 50 and has a dielectric layer 100 that has been processed to form metal lines 101 therein. The metal line is typically formed by etching into a trench in the dielectric layer 100 and then filling the trench with a conductive material such as copper.

[0021] [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com