Method for preparing ZnO nanorods array

A technology of nanorod array and seed layer is applied in the field of preparation of ZnO nanorod array, which can solve the problems of uneven distribution and large difference in size of ZnO nanorods, and achieve the effect of improving product quality and shortening preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

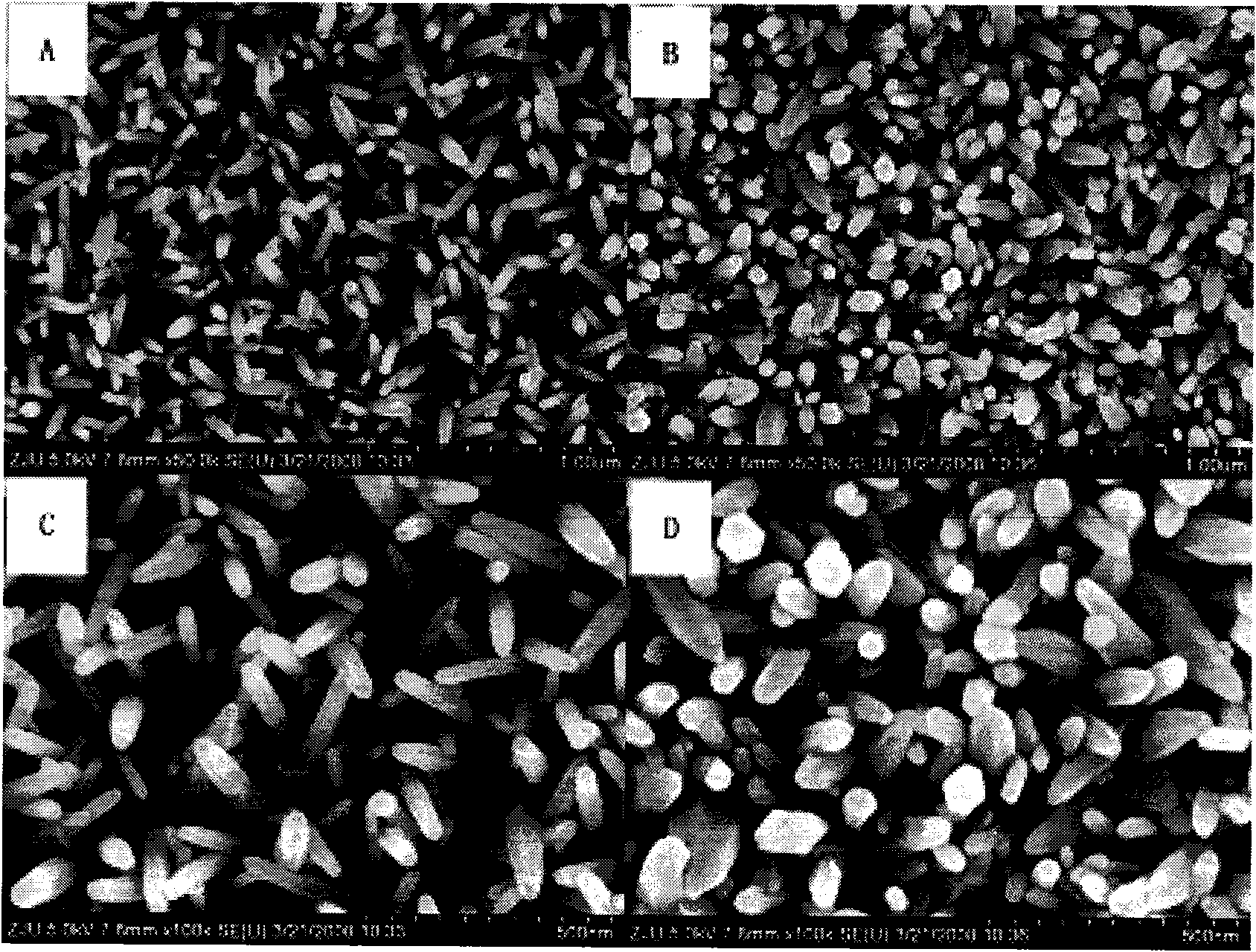

Image

Examples

Embodiment Construction

[0010] The preparation method of the ZnO nanorod array of the present invention is firstly the preparation of the dielectric layer. The silicon wafer selected as the substrate is cleaned and placed in a high-temperature furnace for thermal oxidation. After thermal oxidation at a temperature of 1140 ° C for 40 minutes, A 50nm thick silicon dioxide layer is grown on the surface of the substrate.

[0011] Then a 100nm-thick Zn film was deposited on the dielectric layer of the silicon substrate by means of DC magnetron sputtering, before which the substrate was cleaned by plasma bombardment. When depositing Zn film, the purity of the zinc target is 99.999%, the diameter of the zinc target and the distance between the target and the substrate are 6cm, and the background vacuum is 1.6×10-4Pa. High-purity argon is introduced through a flow control system. The working pressure in sputtering was kept at 1.0 Pa. The sputtering power was 50W, and the time lasted 20min. Under atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com