Free-cutting Mg-Ca brass and preparation method thereof

A magnesium-calcium brass and easy-cutting technology, which is applied in the field of green and environment-friendly lead-free free-cutting magnesium-calcium brass alloy and its preparation, can solve problems such as the lack of independent intellectual property rights, and achieve benefits to human health and environmental protection, production The effect of simple process and cost reduction

Inactive Publication Date: 2009-10-07

CENT SOUTH UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the research on the substitution of lead-free brass mainly includes bismuth brass and antimony brass, but domestic research on bismuth and antimony brass has not yet formed independent intellectual property rights

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

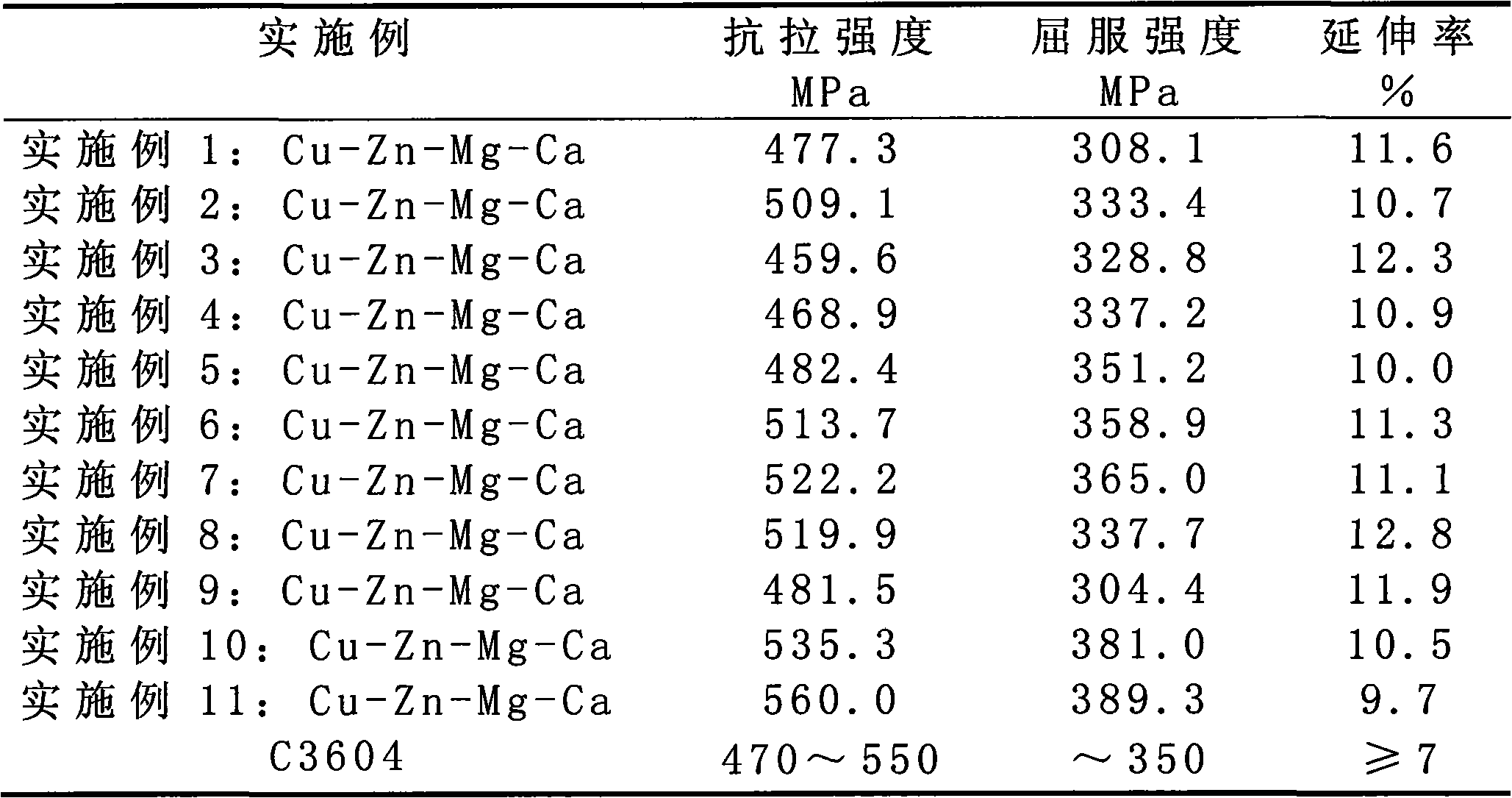

[0030] Embodiment 2: cutting index is greater than 76%;

Embodiment 3

[0031] Embodiment 3: cutting index is greater than 80%;

Embodiment 4

[0032] Embodiment 4: cutting index is greater than 81%;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

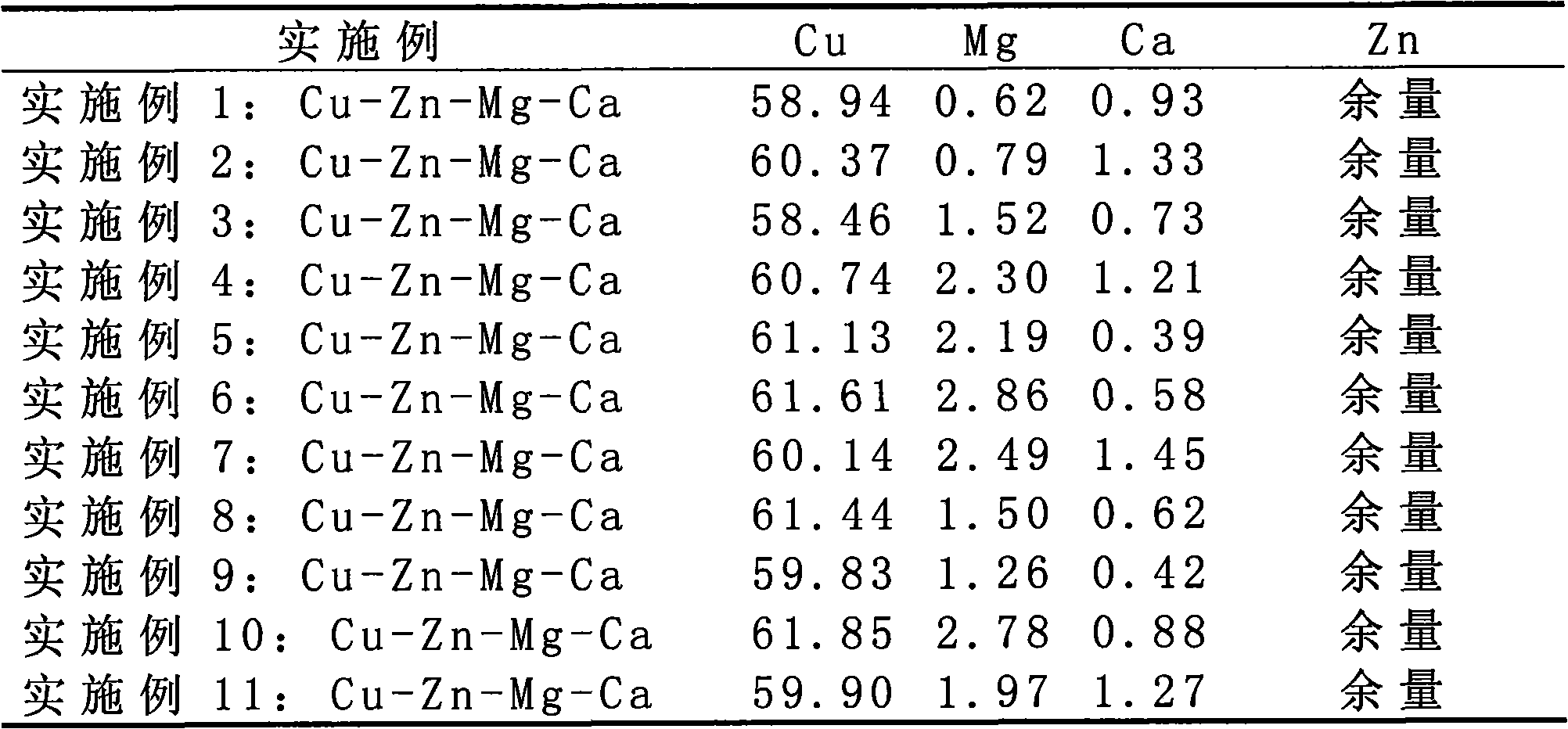

The invention discloses a free-cutting Mg-Ca brass and a preparation method thereof, the Mg-Ca brass consists of copper, zinc, magnesium, calcium alloy elements and unavoidable impurities. The alloy comprises: 58-62 wt% of the copper, 0.5-3.0wt% of the magnesium, 0.1-1.5 wt% of the calcium and the balances as the zinc and the unavoidable impurities, the total content of the impurities is less than 0.1 wt%. The invention also discloses a preparation method for lead-free Mg-Ca brass. On the basis of present normal lead brass, the invention uses the magnesium and calcium elements to replace the lead element that jeopardizes environment and human body severely in consideration of main using performance and demand of the material, and meanwhile, in accordance with the requirements of environmental protection of countries all around the world, especially the developed countries, thus meeting the environmentally-friendly demand. The alloy also has excellent casting property, processing property, dynamic property, corrosion resistance and cutting property, and can take the place of the present lead Mg-Ca brass, moreover, the invention is low in manufacturing cost and can be applied to water-heating and bathroom apparatuses as well as to other various production fields.

Description

technical field [0001] The invention relates to brass and a preparation method thereof, in particular to an environmentally friendly lead-free free-cutting magnesium-calcium brass alloy with excellent cutting performance, mechanical performance and corrosion resistance and a preparation method thereof. Background technique [0002] Lead brass has excellent properties such as easy cutting, mechanics, and physics. It is a widely used copper alloy. In developed countries, the utilization rate of only brass water pipes is as high as 90%. However, lead is a harmful effect on the environment and human body. As a huge element, lead exists in the form of free simple substance in lead brass, and enters the water with the corrosion of lead brass, so the lead content of various products must be strictly controlled in industrial production. At present, the alternative research of lead-free brass mainly includes bismuth brass and antimony brass, but domestic research on bismuth and antim...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/04C22C1/02C22F1/08C21D1/30

Inventor 肖来荣易丹青张路怀周宏明刘彦柳公器胡加瑞

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com