Selective plating device

An electroplating device and selective technology, applied in plating baths, circuits, semiconductor devices, etc., to reduce material waste, reduce pollution, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

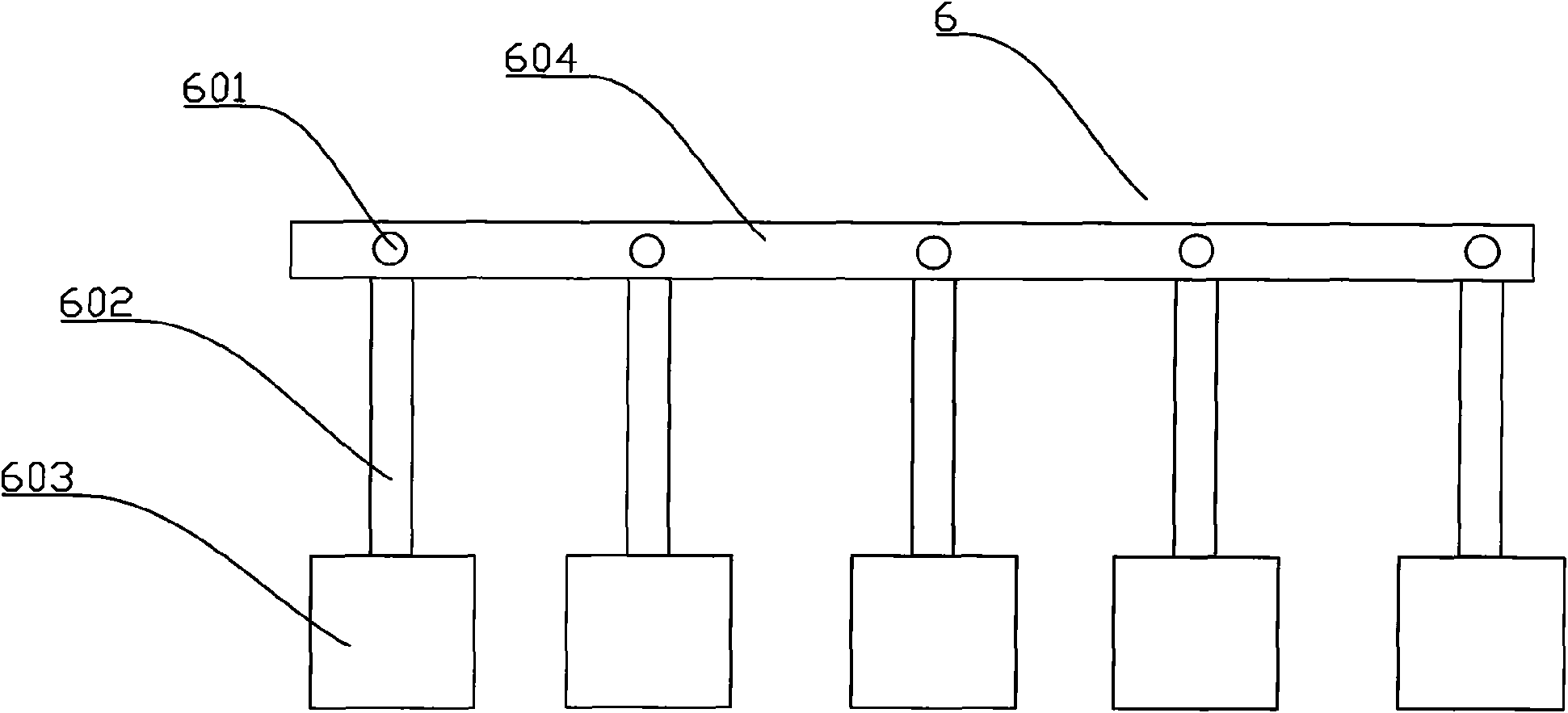

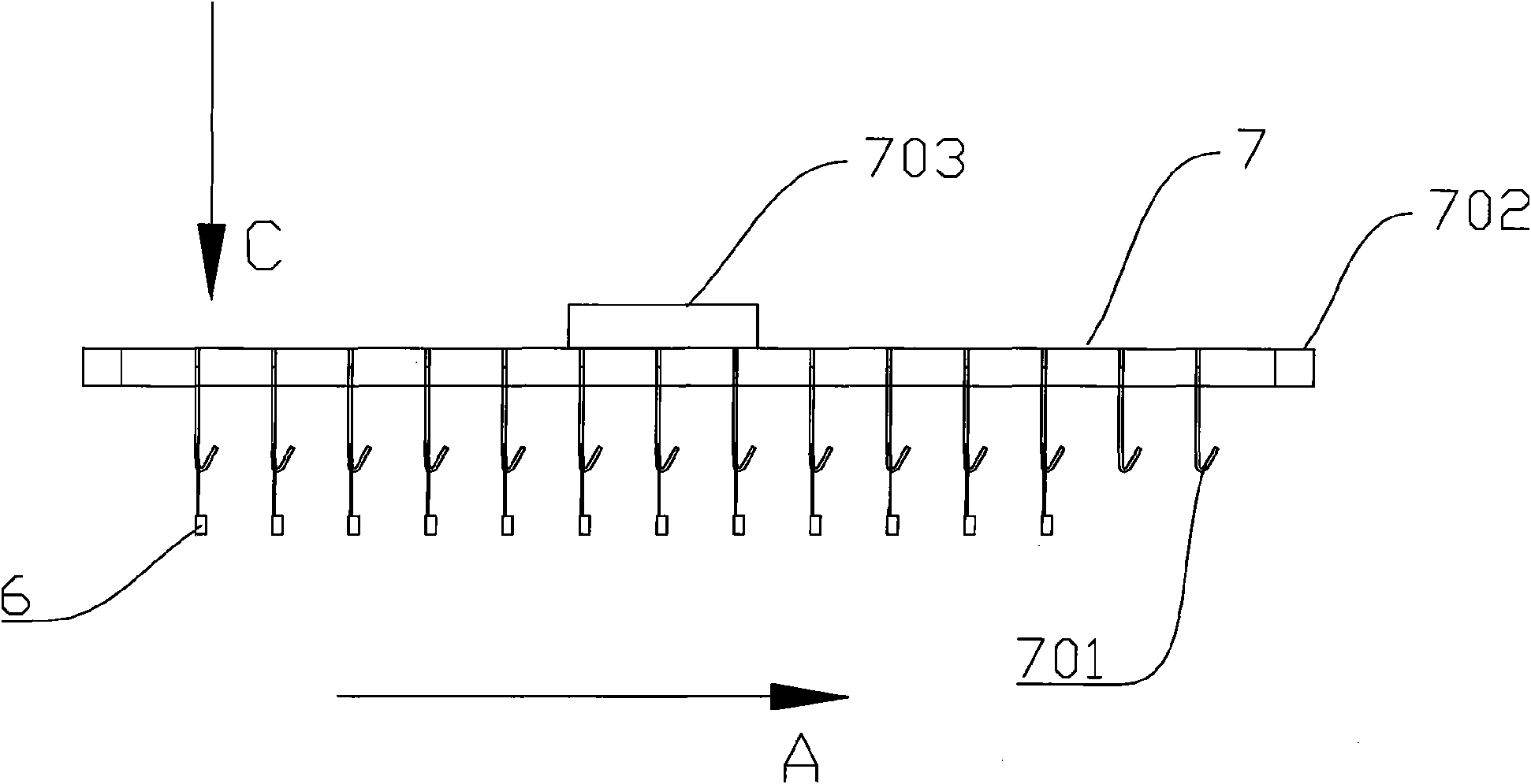

[0044] Selective plating devices such as image 3 , Figure 4 As shown, the hook support frame 7 includes two parallel frames 702 and a beam 703, the two frames 702 are connected as a whole through the beam 703, the beam 703 exceeds a part of the frame 702, and the conductive hook 701 is installed on the frame 702. A group of hooks 701 are respectively located on the two frames 702, and the two hooks are arranged in a straight line to form a group to hang a lead frame. The number of the hooks 701 is more than two groups, and more than two groups of the hooks 701 are arranged along the direction parallel to the liquid surface of the electroplating solution, that is, the A direction in the figure, and the number of groups of the hooks can be determined according to actual production needs.

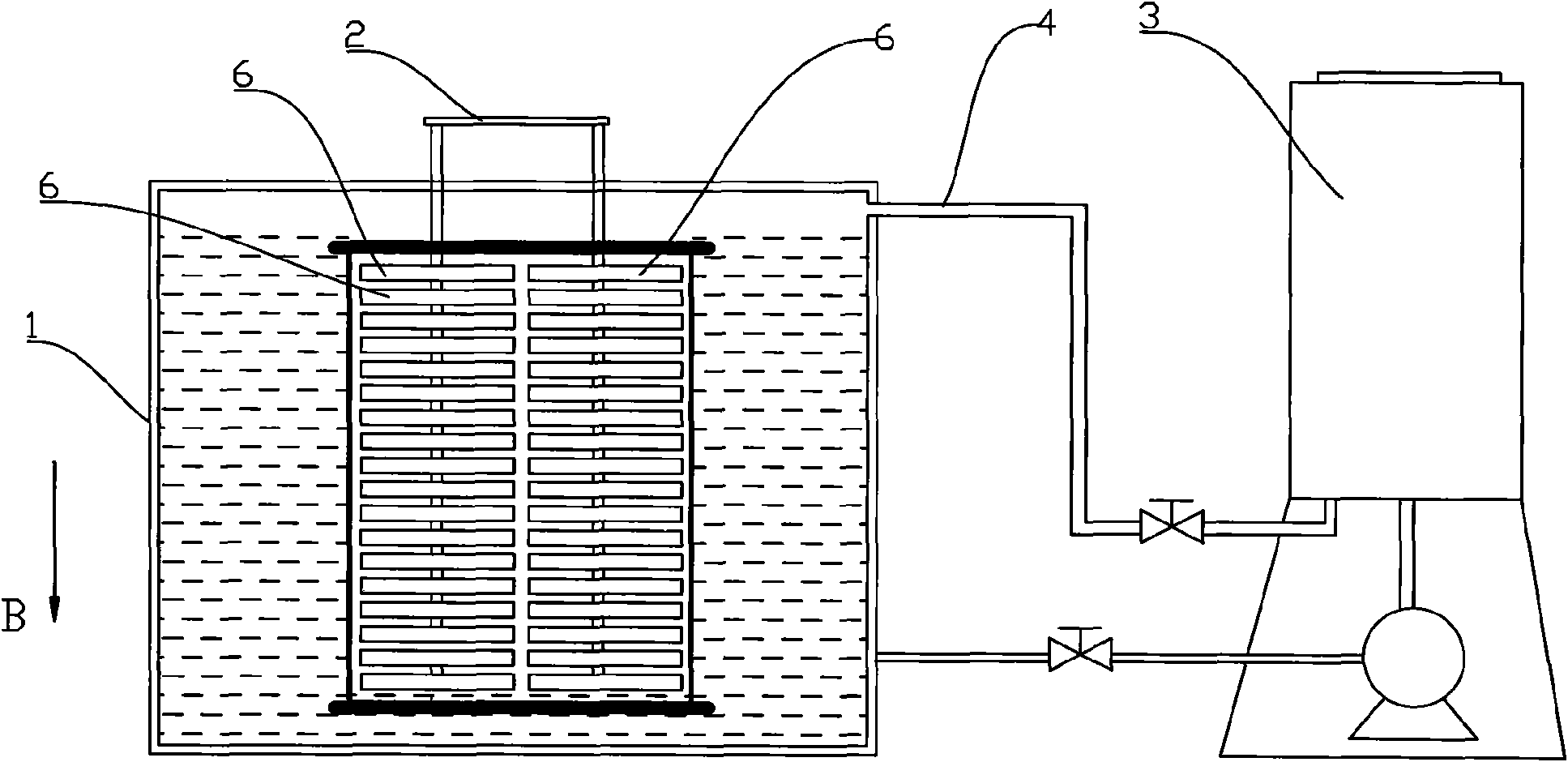

[0045] Such as Figure 5 As shown, the electroplating solution tank 5 is also included, and the part of the beam 703 beyond the frame 702 is mounted on the tank wall of the electroplating ...

Embodiment 2

[0048] It differs from Example 1 in that, as Figure 8 As shown, an overflow hole 506 is provided on the wall of the electroplating solution tank 5, and the overflow hole 506 replaces the overflow tank of the first embodiment, and the rest of the structure is the same as that of the first embodiment.

Embodiment 3

[0050] It differs from Example 1 in that, as Figure 9 As shown, the number of beams 703 is two, and the two beams 703 can ensure the stable placement of the entire frame and reduce shaking, and the rest of the structure is the same as that of Embodiment 1.

[0051] The number of beams 703 can also be adjusted according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com