Measuring method of depth of metal surface hardening layer with curve surface

A technology of hardened layer depth and metal surface, applied in measuring devices, instruments, optical devices, etc., can solve the problems of complex post-processing and difficult application, and achieve the effect of good consistency and simple and practical measurement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A method for measuring the depth of a hardened layer on a metal surface with a curved surface. The specific implementation process is as follows:

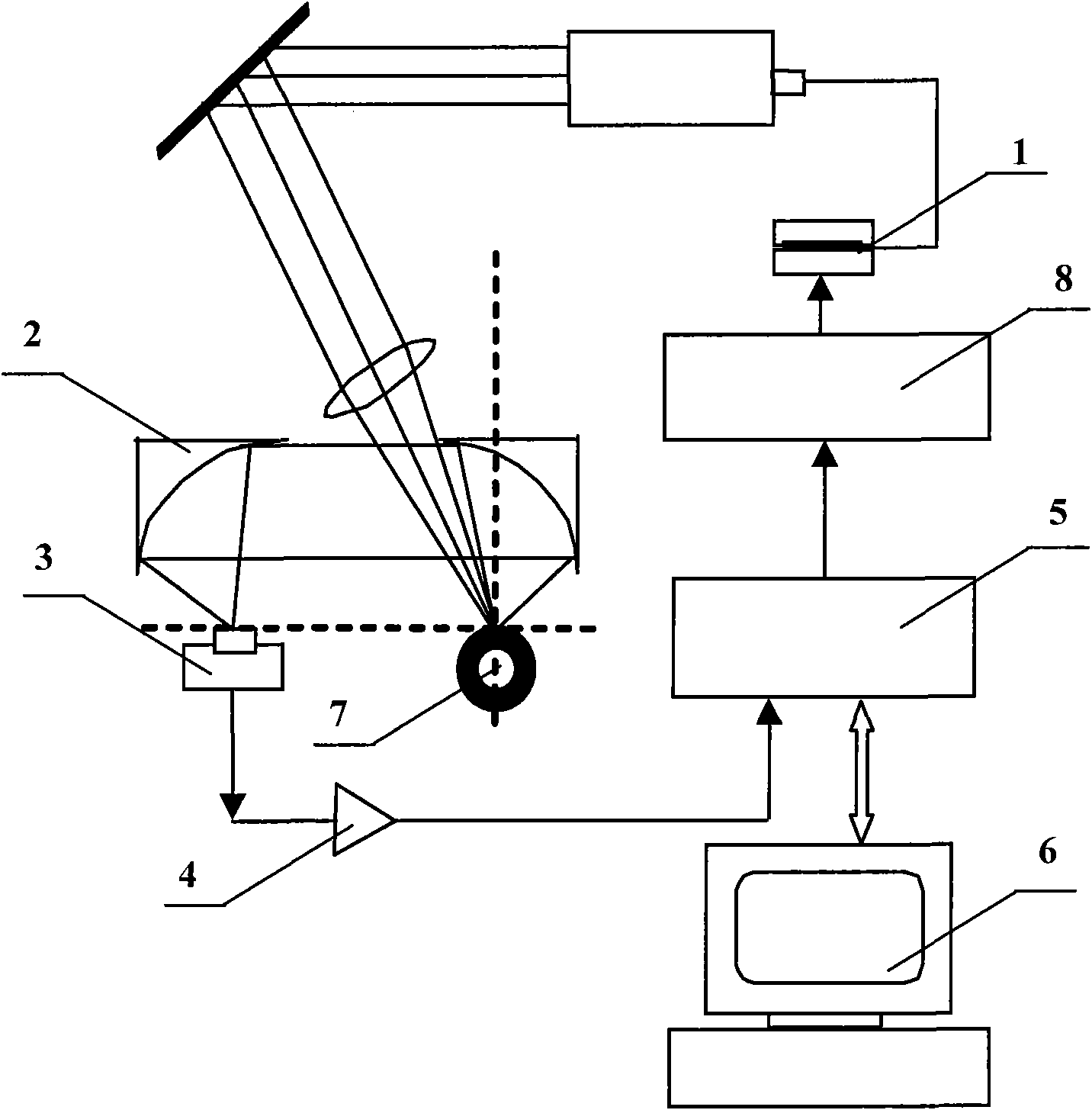

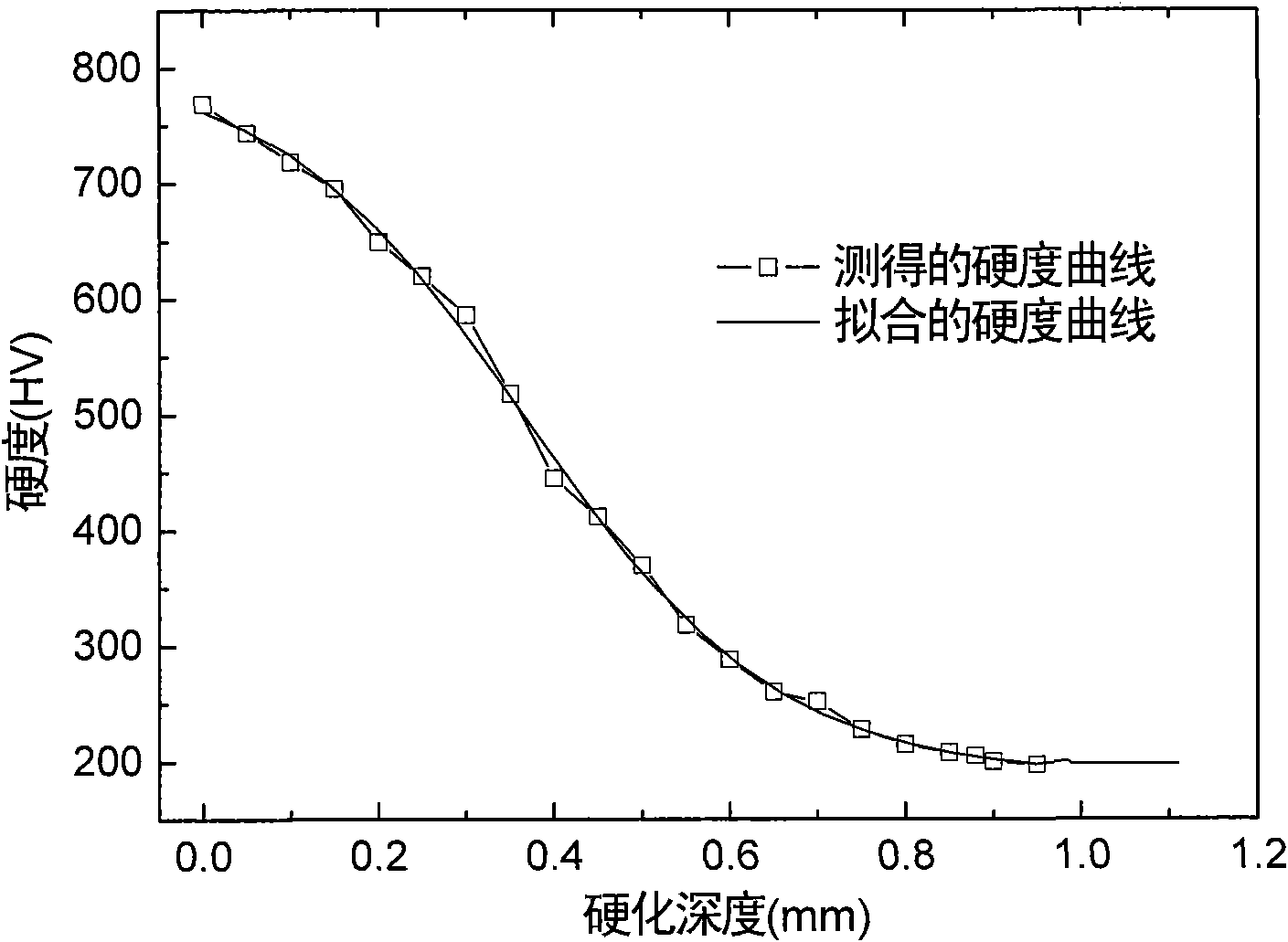

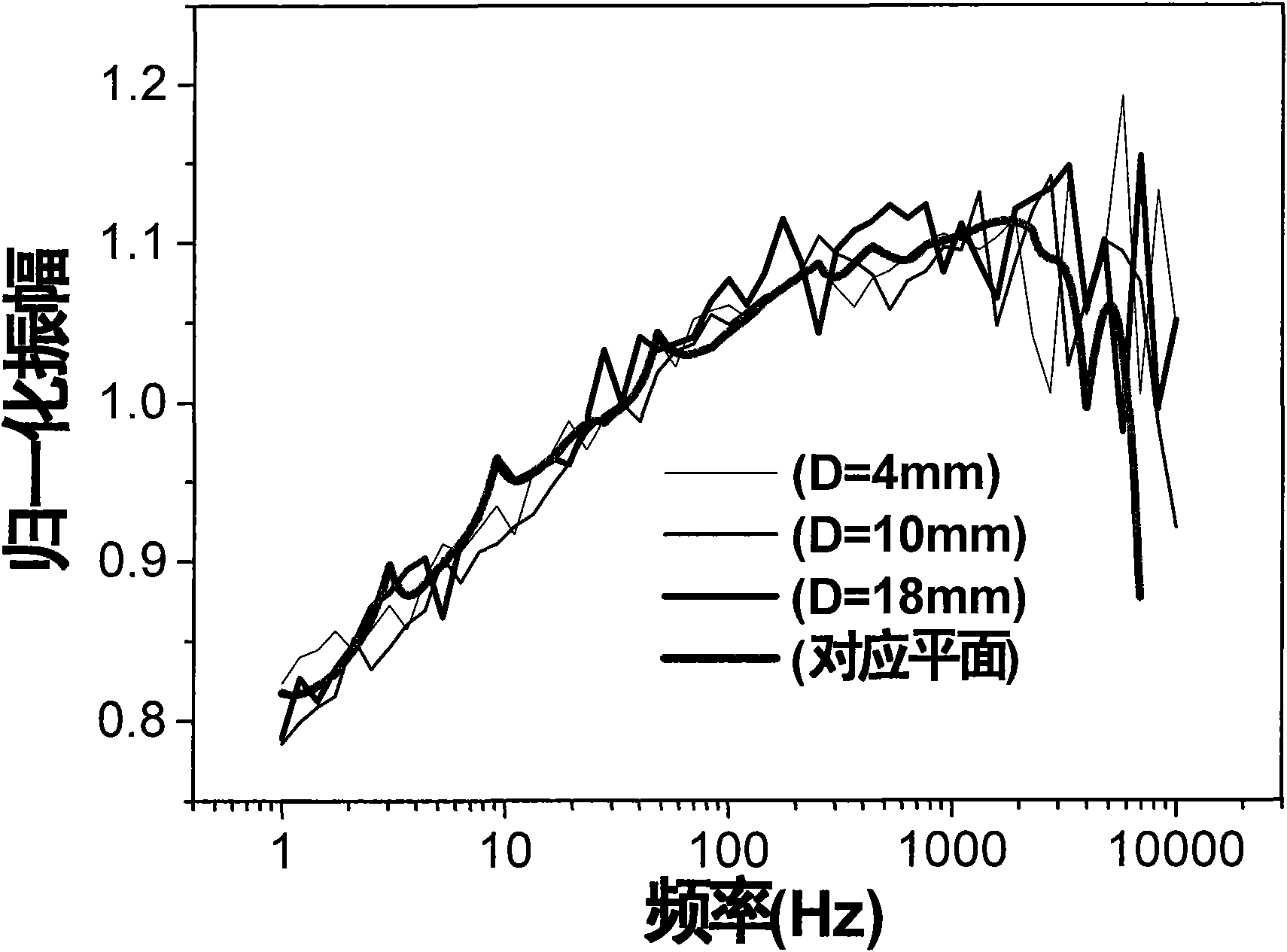

[0042] The experimental sample is a non-uniform cylinder of AISI1020 steel (C: 17%-23%, Mn: 35%-65%, P≤3.5%, S≤3.5%) that has undergone surface heat treatment. The sample diameters are D=18mm, D =10mm and D=4mm, both of which are 30mm in length. There are two cylindrical samples of each size, one of which is surface hardened and the other is not hardened, as a reference sample. The thermophysical coefficient of AISI1020 steel is k=50.63W / mK, ρ=7850g / cm 3 , C=468.608J / kg℃, α=k / ρc=13.7663×10 -6 (m 2 / s). The experimental measuring device is attached figure 1 As shown (see Table 1 for the performance and parameters of each instrument), it is mainly composed of Jenoptik semiconductor laser 1, power supply 8, beam expansion system, off-axis parabolic mirror 2, HgCdTd infrared detector 3, Ge filter, preamplifier 4, The l...

Embodiment 2

[0066] Embodiment 2: Theoretical analysis of the detection method of the present invention

[0067] (1) Cylindrical sample model and calculation formula

[0068] Set a beam of light intensity I 0 , The laser beam with modulation frequency f(w=2πf) is irradiated on the cylindrical sample, the sample absorbs the light and causes the temperature change and the change of infrared radiation, and the corresponding infrared detector (such as HgCdTe) can detect the sample Thermal radiation-the photothermal signal. It is assumed that the surface hardening layer is an uneven layer composed of multiple layers, that is, a multi-layer cylindrical model composed of N layers of different materials. k i , Α i Respectively represent the thermal conductivity and thermal diffusivity of the i-th layer; a i And a i+1 Denote the outer radius and inner radius of the i-th layer, respectively.

[0069] The temperature field at any point on the cylindrical surface can be expressed as:

[0070]

[0071] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com