Liquid crystal display and manufacturing method thereof

A technology for a liquid crystal display screen and a manufacturing method, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of liquid crystal pollution, uneven cell thickness, affecting the display effect of image quality, etc., so as not to peel off and avoid glue breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

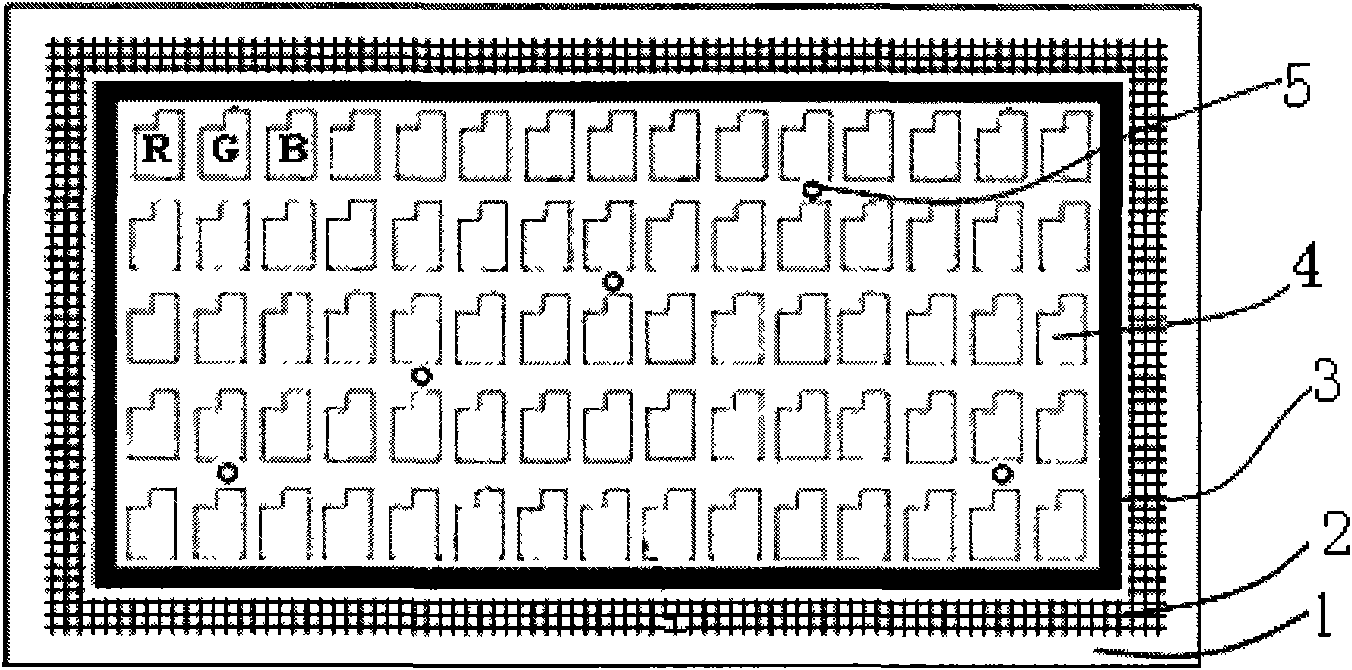

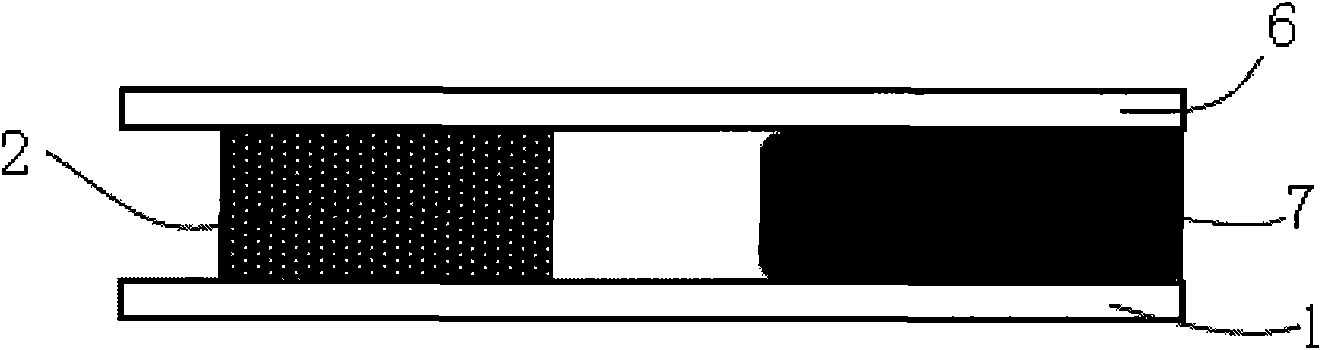

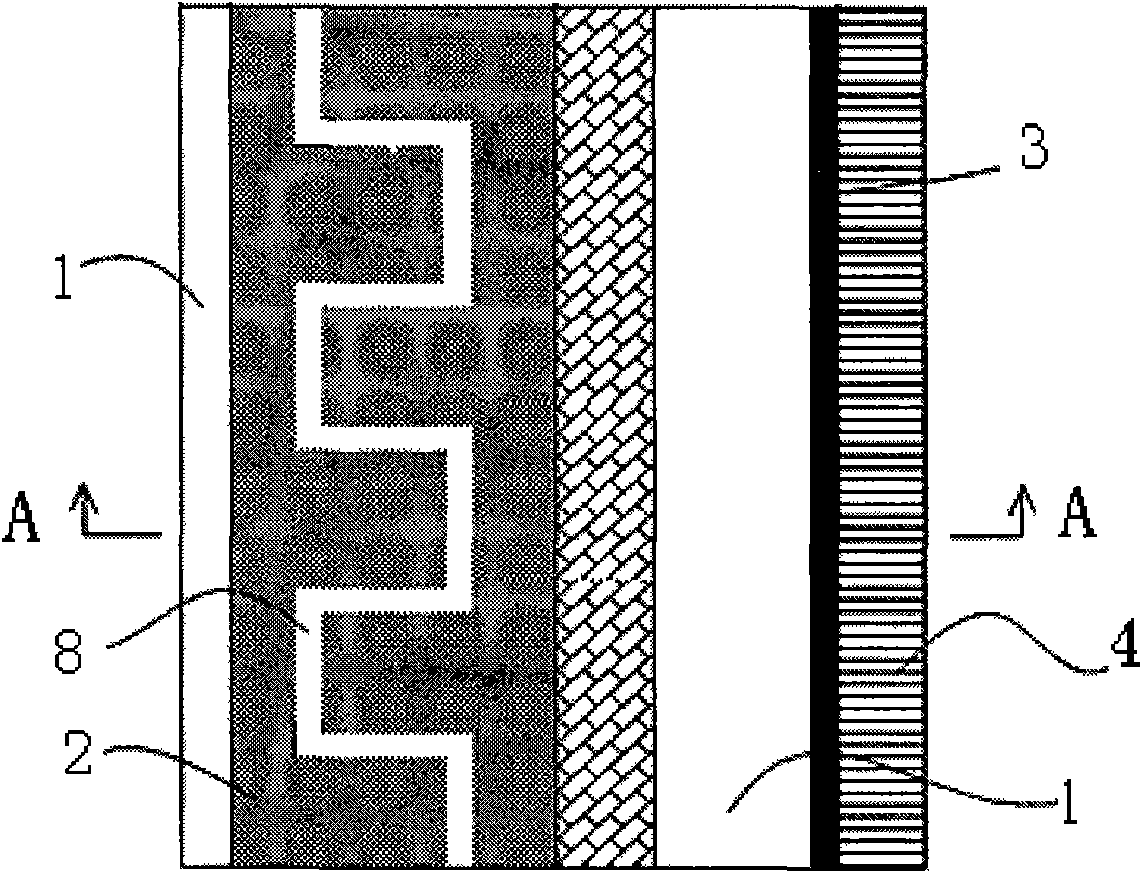

[0033] Such as figure 1 , image 3 and Figure 4 As shown, the liquid crystal display of the embodiment of the present invention includes an array substrate 1, a color filter substrate 6 disposed opposite to the array substrate 1, a display area 4 of the array substrate 1 and the color filter substrate 6, and a display area 4 located on the color filter substrate 6. The surrounding light-shielding layers 3 are filled with liquid crystal 7 and spacers 5 for maintaining the thickness between the array substrate 1 and the color filter substrate 6, and the periphery of the display area 4 is sealed by the sealant 2, and the periphery of the sealant 2 is set. There is a protective layer of silicon nitride material, and the protective layer includes an outer protective layer 91 and an inner protective layer 92. In this embodiment, the outer protective layer 91 is formed on the periphery of the side of the sealant 2 away from the display area 4, and the inner protective layer 92 is f...

Embodiment 2

[0038] Such as Figure 5As shown, the embodiment of the present invention is basically the same as the embodiment 1, the difference is that in this embodiment, only the outer protective layer 91 is provided on the periphery of the sealant 2, and the outer protective layer 91 is perpendicular to the direction of the array substrate 1 The thickness is equal to the cell thickness of the liquid crystal display. During the coating of the frame sealant 2 and the process of box alignment, glue bubbles will be generated in the frame sealant 2, and in severe cases, the sealant 2 will be broken. In the embodiment of the present invention, multiple layers can be set on the outer protective layer 91. The through hole 93 whose direction is parallel to the array substrate 1 and which can communicate the frame sealant 2 with the external environment is used to discharge the glue bubbles generated in the frame sealant 2 so as to avoid glue breakage. The outer protective layer 91 is directly ...

Embodiment 3

[0041] Such as Figure 7 As shown, the embodiment of the present invention is basically the same as the embodiment 1, the difference is that in this embodiment, only the inner protection layer 92 is provided on the periphery of the sealant 2, and the inner protection layer 92 is perpendicular to the direction of the array substrate 1 The thickness is equal to the cell thickness of the liquid crystal display. The inner protective layer 92 in this design can effectively isolate the frame sealant 2 from the liquid crystal 7, even if the frame sealant 2 changes with the influence of external temperature, time and humidity, it will not affect the liquid crystal 7, and at the same time increases The strength and hardness of the frame sealant 2 make the frame sealant 2 firmer and less prone to peeling off after the box is cured, and can play the role of a spacer to maintain the thickness of the box between the array substrate 1 and the display area 4 of the color filter substrate 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com