Electric drive of automobile

A pure electric drive technology, applied in the direction of motors, electric vehicles, electric components, etc., can solve the problems of a single permanent magnet activating the potential kinetic energy and not fully utilizing the potential energy of the permanent magnet, so as to achieve large output, small temperature rise, and high energy consumption. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preferred embodiment of the present invention is shown in the accompanying drawings. The present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

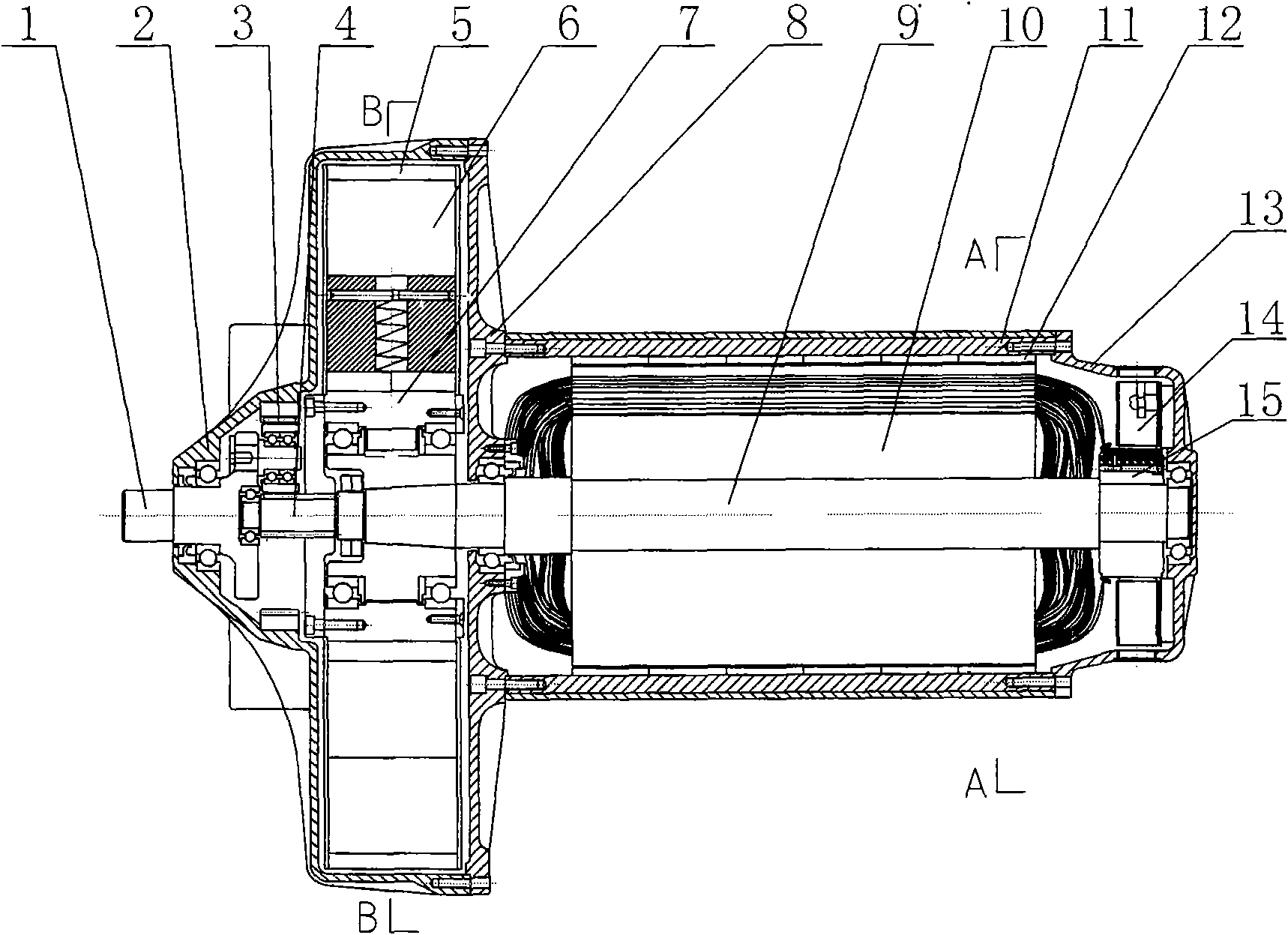

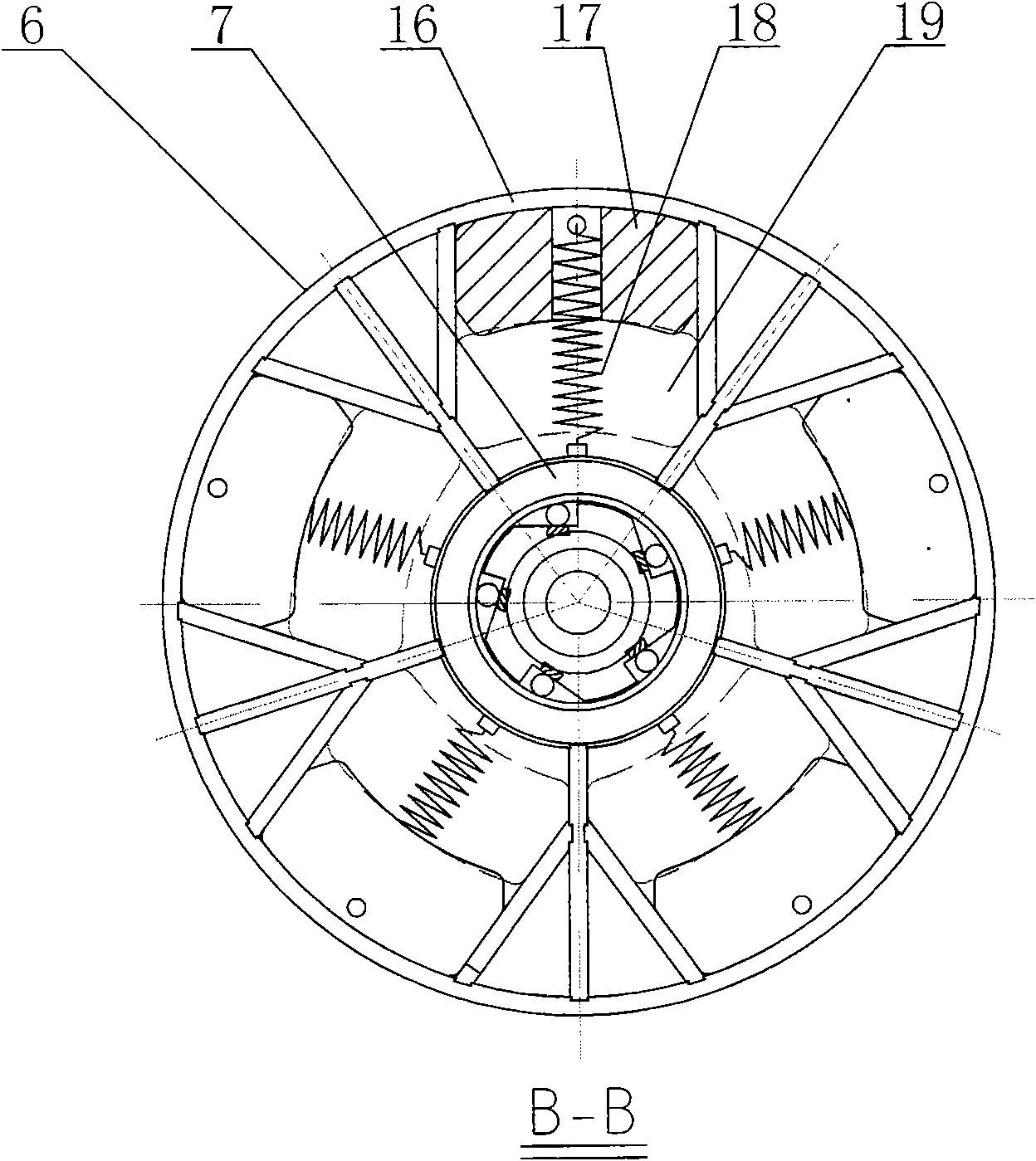

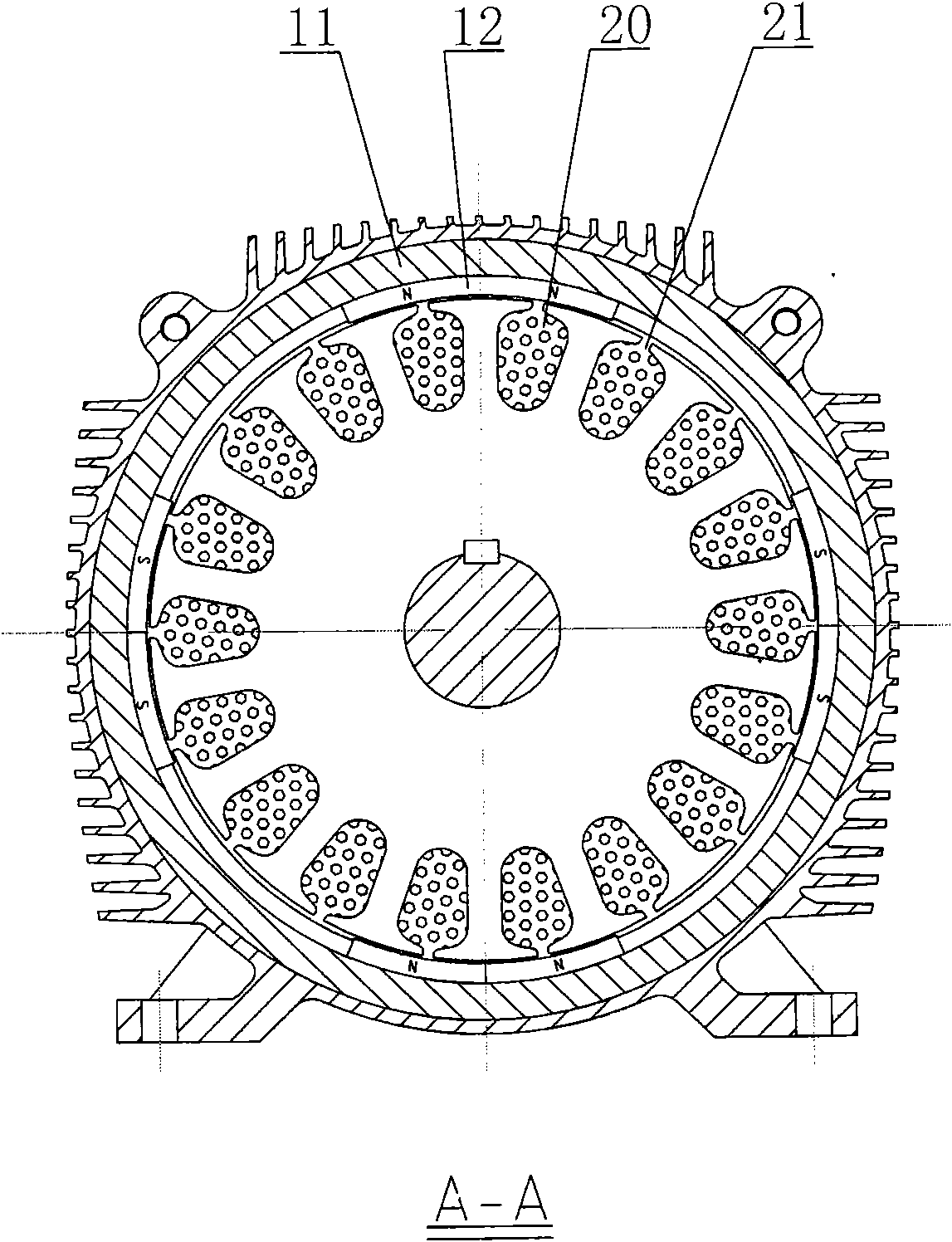

[0012] Depend on figure 1 As can be seen, the present invention includes a motor housing 11, a main shaft 9, a rotor 10 embedded with windings, and a permanent magnet 12 arranged on the inner circumference of the housing 11. The present invention also includes a reversing device 15, energy storage and energy conversion Device 5 and deceleration device 3. It can be seen from the figure that the reversing device 15 is fixedly installed on one end of the motor main shaft 9 , its hanging legs are fixedly connected with the coil head of the winding, and the end face is engaged with the electric brush 14 . Please also see figure 2 The energy storage and energy conversion device 5 includes an inertial energy storage disc 6 and a one-way overrunning clutch 7, the one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com