On-orbit car wheel lathe being capable of processing multiunit wheels simultaneously

A wheel lathe and wheel technology, which is applied to metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of insufficient rigidity of machine tools, affecting processing accuracy, uneven force on friction rollers, etc., to improve processing efficiency and improve processing accuracy. , The effect of reducing the geometric size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

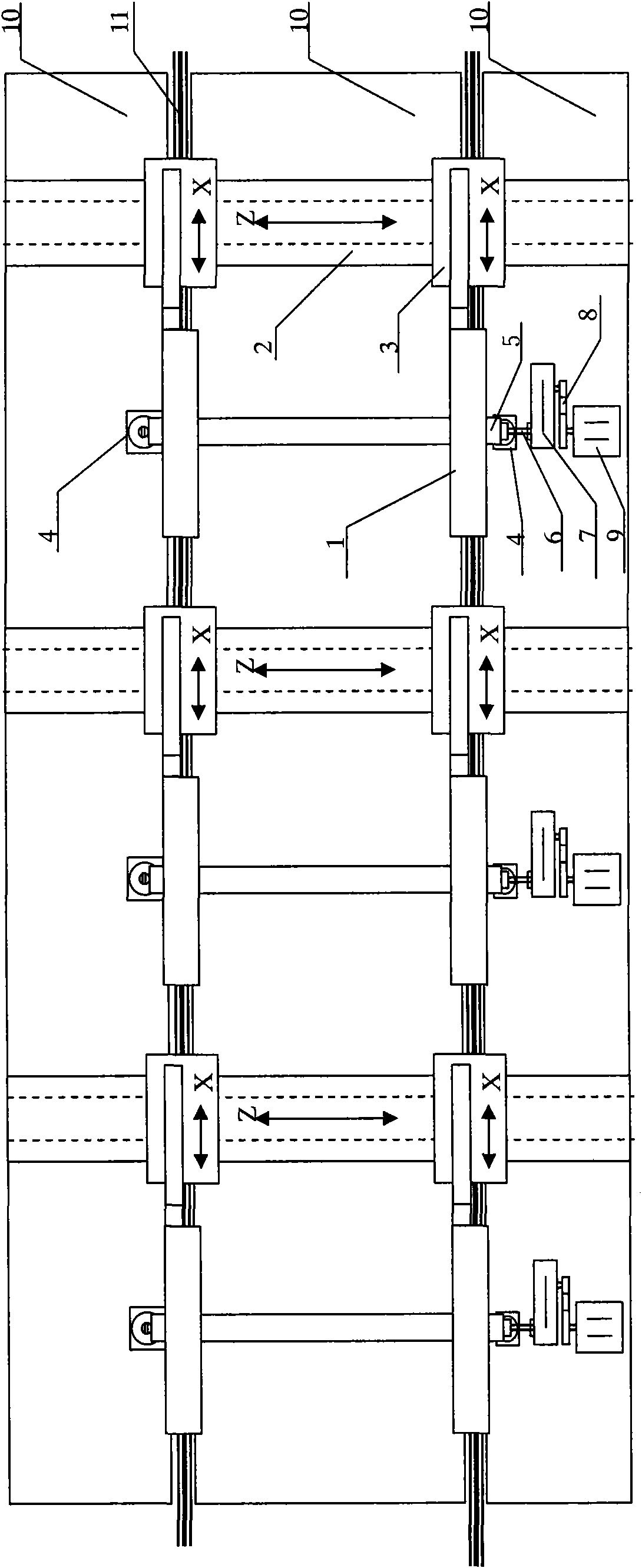

[0027] The present invention will be described in detail below with reference to the accompanying drawings.

[0028] Overall structure: The flat bed 12 is the basic structural part of the machine tool, on which other components such as the hydraulic system, the main transmission system, and the numerical control system of the tool post are placed on it, and it is used as a process benchmark to ensure machining accuracy. 13 is a steel rail, and the rolling stock to be processed is drawn from the steel rail to the designated position of the lathe to stay.

[0029] Main drive system: mainly composed of motor, pulley, cardan shaft and other components. The three-phase AC motor 6 transmits the power to the gearbox 8 through the pulley 7, and after the gearbox is decelerated, it is output by the output flange of the gearbox, and the power is transmitted to the connecting flange connected to the main shaft through the universal coupling 9. Joint 10 directly drives wheel pair 11 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com