Device and method for monitoring slow-speed and over-load rotor eccentricity image

A technology for rotor eccentricity and image monitoring, which is applied to measurement devices, optical devices, instruments, etc., can solve the problem of difficulty in giving the value of eccentricity, and achieve the effect of simple structure and convenient method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the example in the accompanying drawings:

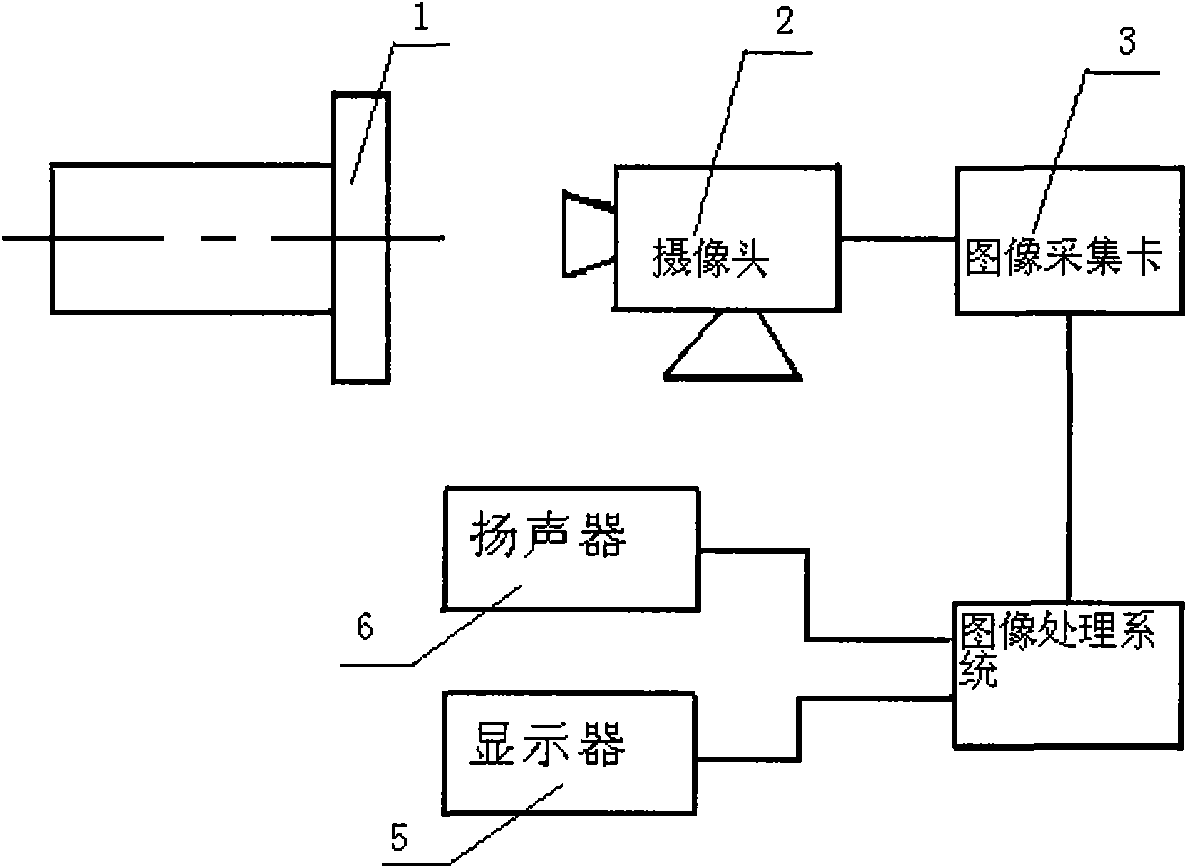

[0019] figure 1 As shown, the low-speed heavy-duty rotor eccentricity image monitoring device is mainly composed of a standard circular part 1, a high-resolution camera 2, an image acquisition card 3, an image processing system 4, a display 5 and a speaker 6. The standard circular part 1 is installed On the tested rotating shaft, the diameter of the standard circular piece 1 is about 50 mm, and the thickness is about 10 mm. The high-resolution camera 2 is arranged in the front of the section of the standard circular piece 1, and the resolution of the high-resolution camera 2 is more than 1280 pixels×800 pixels. The high-resolution camera 2 takes pictures of the standard circular piece 1 at the end of the rotary shaft. The high-resolution camera 2 is connected to the image acquisition card 3, and the image acquisition card 3 is connected to the image pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com