Rotary piston internal combustion engine

A technology of rotary piston and internal combustion engine, applied in the direction of rotary piston engine, rotary or oscillating piston engine, internal combustion piston engine, etc., can solve problems such as self-braking, friction loss, air leakage, etc., to reduce structural complexity and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

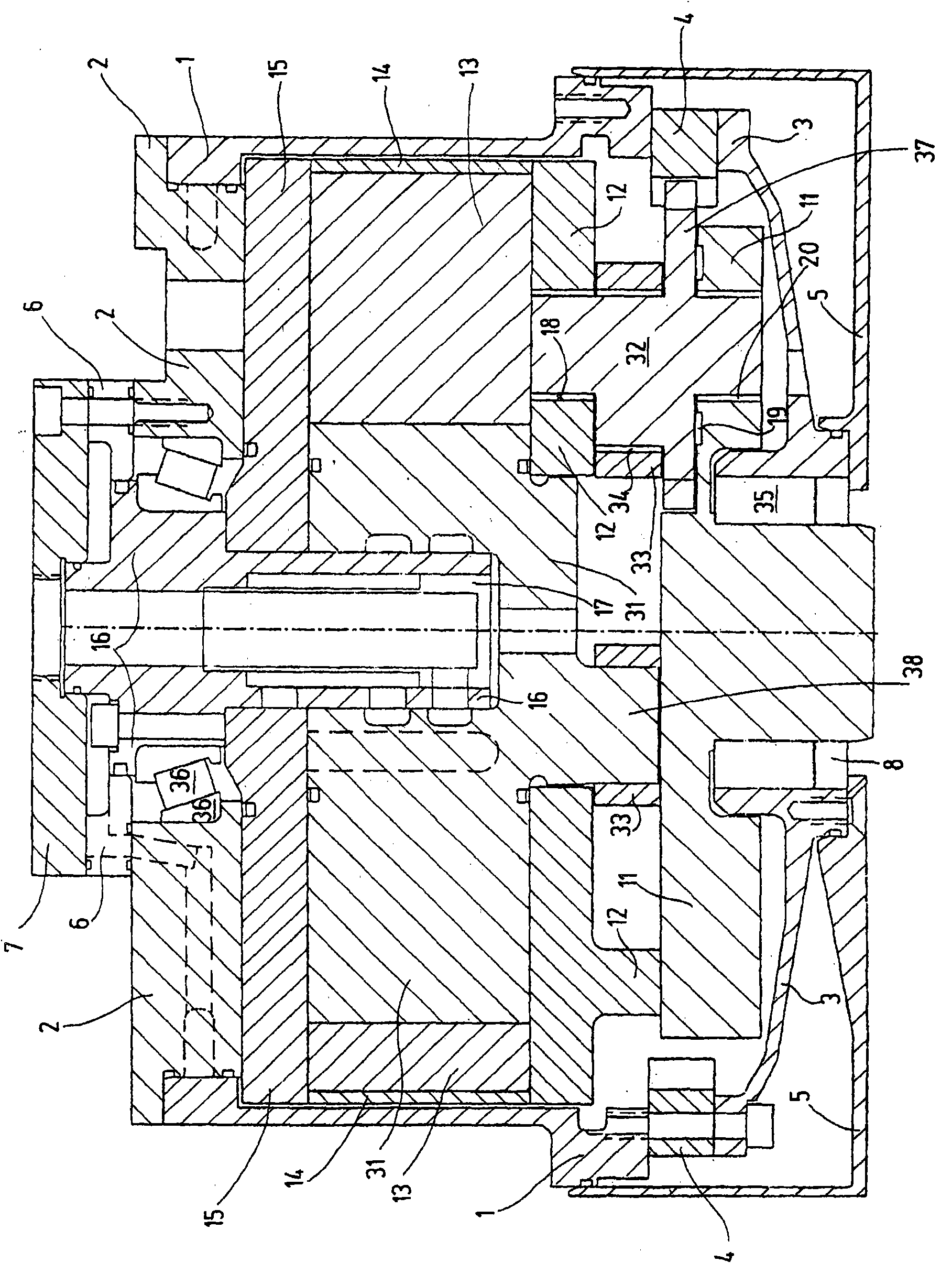

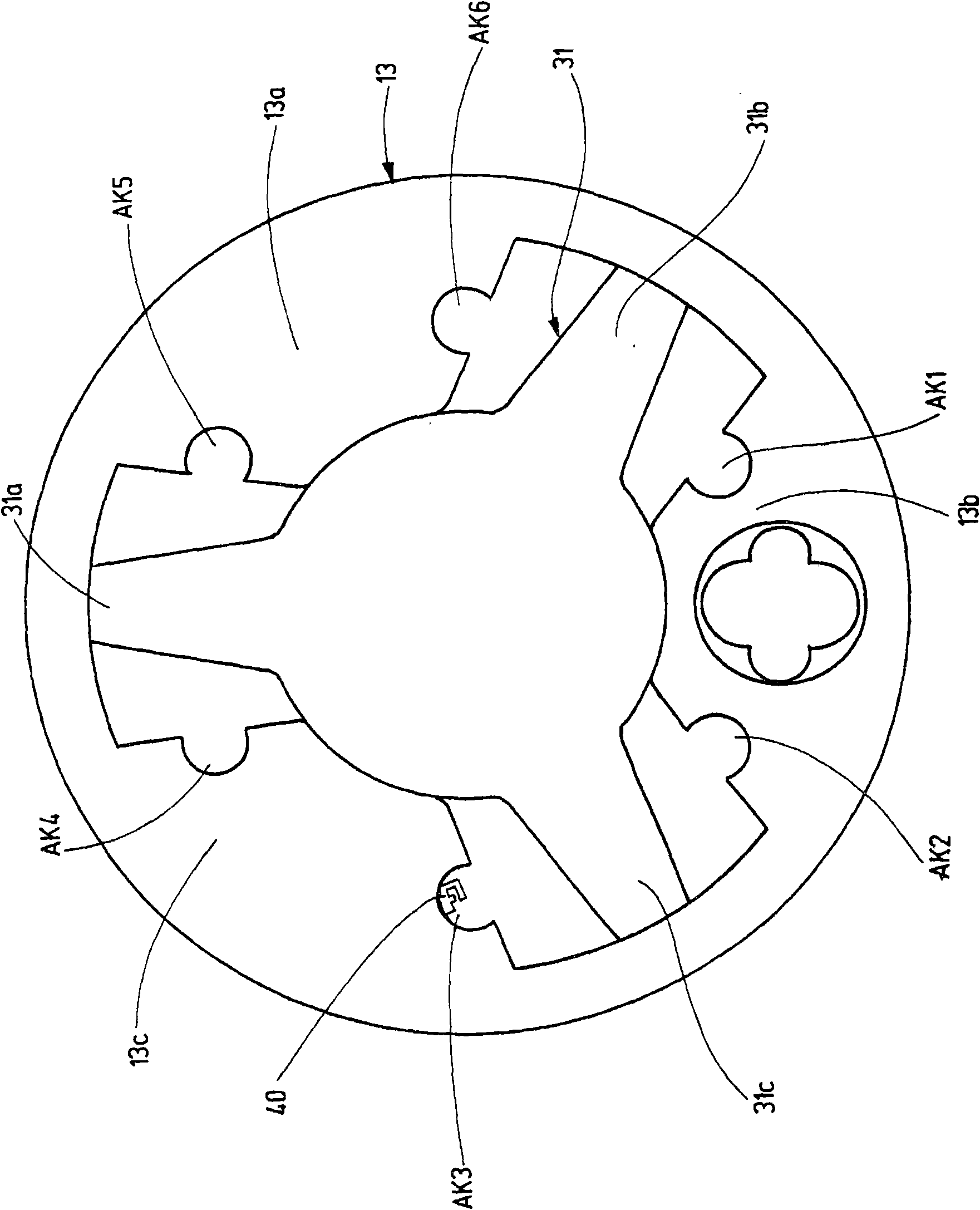

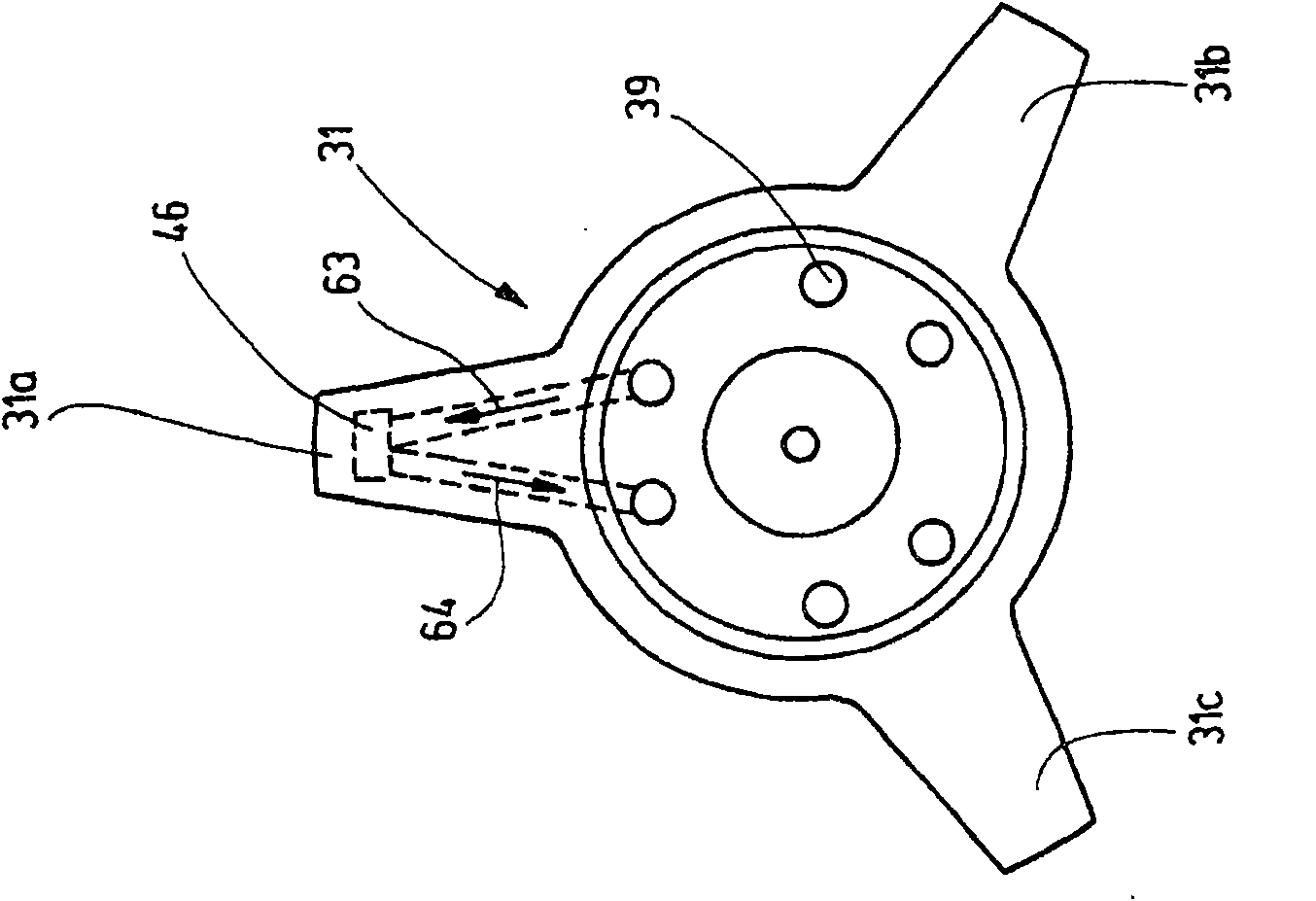

[0026]The rotary piston internal combustion engine shown in the figure is a Sabet engine with an axial charge exchange device and three pistons each and three opposing pistons. The engine is equipped for operation with a vertical shaft, which is positioned vertically, and the piston and counter-piston rotate in a horizontal plane. Such a device can be used, for example, on a boat engine or on a servomotor to generate electricity with a power of up to about 20-30 kW.

[0027] figure 1 The internal combustion engine shown in longitudinal section in , comprises a stationary assembly and a rotating assembly, wherein the stationary assembly essentially consists of: a housing 1 with a driven-side upper housing cover 2 and a lower housing cover 3; The internal gear 4 connected with the housing; the oil tank 5 fixed on the lower housing cover 3 . Also belonging to the fixed components are the oil distribution plate 6 ; the associated cover 7 , on which an oil supply point is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com