Method for preparing vanadium dioxide and doping powder thereof by combustion method

A technology of vanadium dioxide and combustion method, which is applied in the direction of vanadium oxide, etc., can solve the problems that it is difficult to obtain VO2 pure phase, difficult to control the valence state of vanadium, difficult to scale production, etc., to achieve superior intelligent energy-saving cycle performance, easy to The effect of enlarging mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

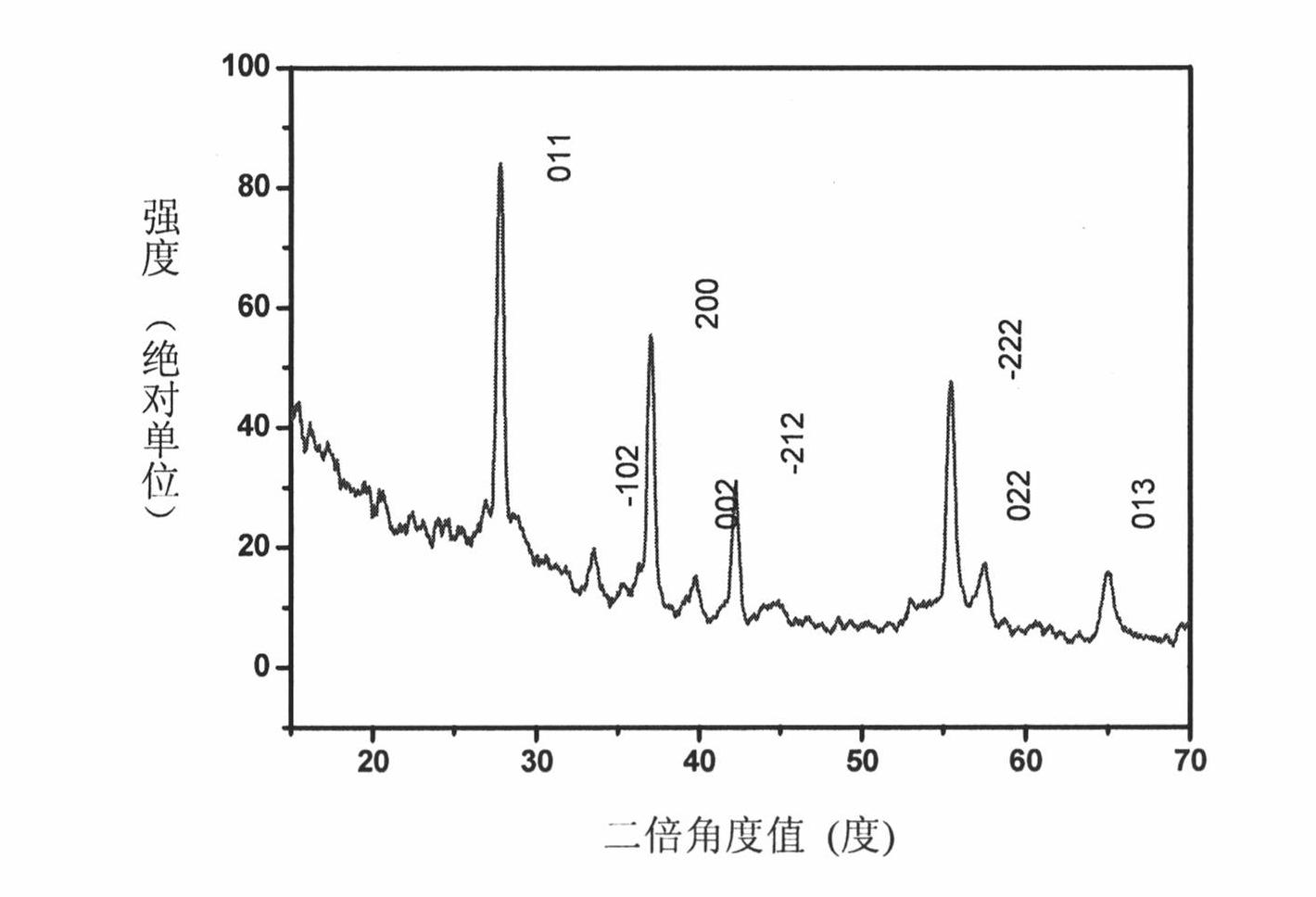

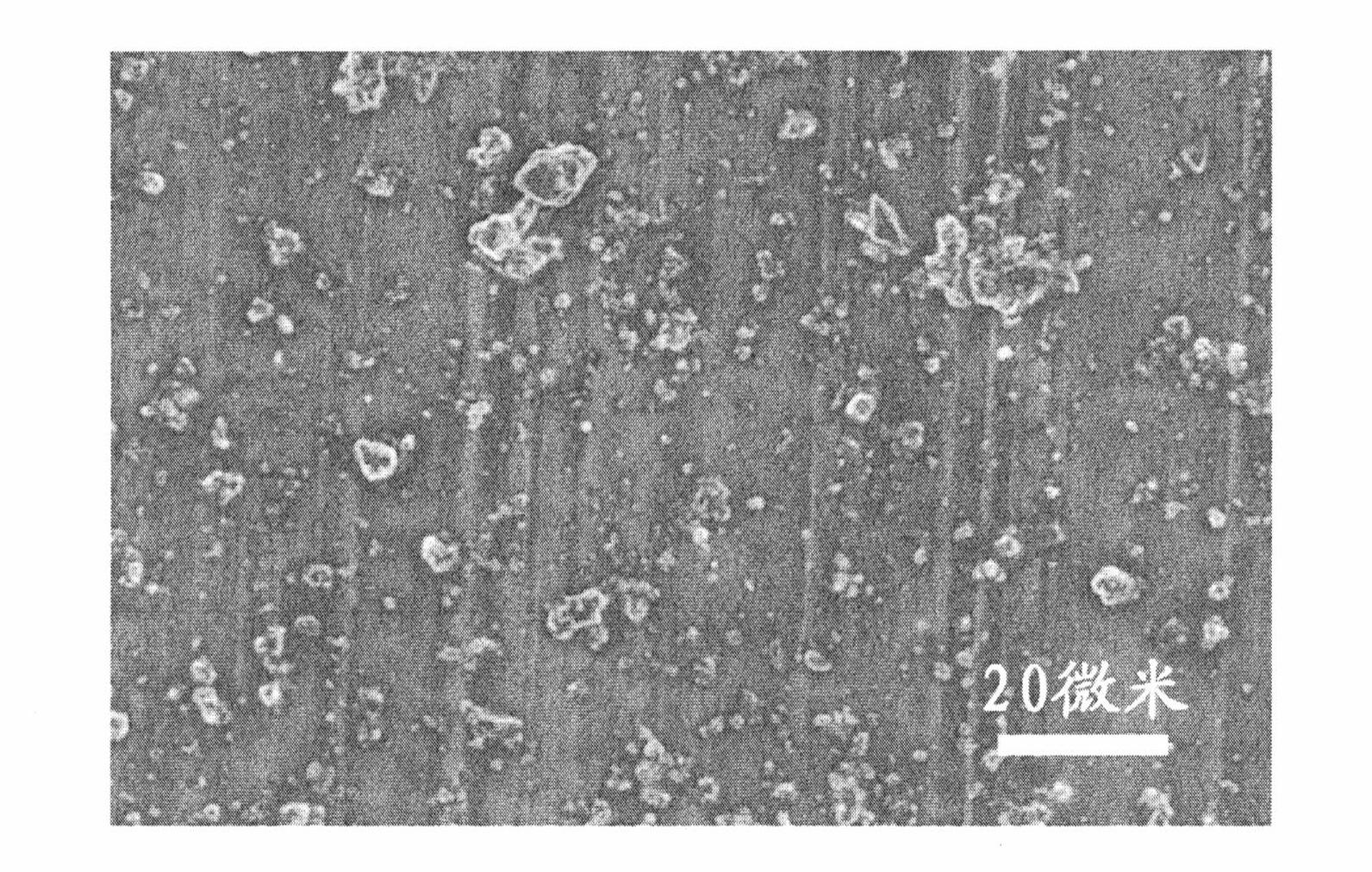

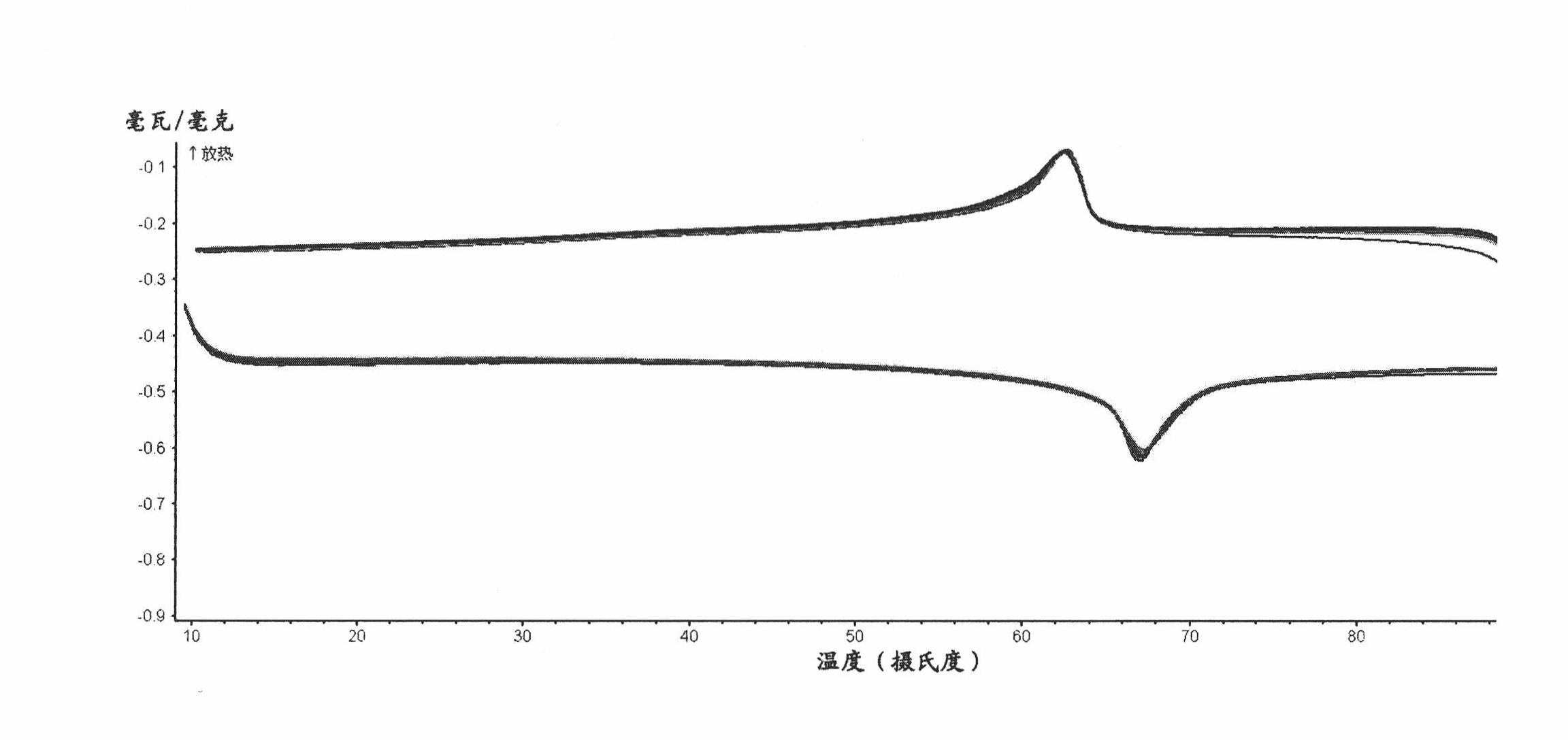

[0033] Monoclinic VO 2 (VO 2 (M)) Realization of powder material: add 1mmol ammonium metavanadate (NH 4 VO 3 ) into 100 mL of organic solvent cyclohexane, and ultrasonically disperse. The combustion ambient temperature is around 25°C. Then directly ignite it with an open flame for about half an hour and the reaction is complete. The resulting sample was washed with pure water. The remaining inorganic ions in the filtrate washed with pure water are obtained by evaporation, and these ions can be reacted in the next step, so that the utilization rate of raw materials reaches 100%. This is convenient to get VO 2 (M) Powder material. Such as figure 1 As shown, all X-ray powder diffraction peaks can be indexed as VO 2 (M) powder and no other impurity peaks appear, so the powder material synthesized by this method is high-purity VO 2 (M) Powder material. figure 2 According to the ordinary FE-SEM photos of the obtained products, it can be seen from the photos that the prod...

Embodiment 2

[0035] Nano-sized monoclinic VO 2 (VO 2 (M)) Realization of solid spheres of powder materials: Add 1mmol sodium orthovanadate powder into 100mL organic solvent methanol in a 250mL glass jar, and the combustion environment temperature is around 25°C. Then directly ignite it with an open flame for about half an hour and the reaction is complete. The obtained sample can be washed with pure water. The remaining inorganic ions in the filtrate washed with pure water are obtained by evaporation, and these ions can be reacted in the next step, so that the utilization rate of raw materials reaches 100%. Figure 4 It is the FE-SEM photo of the nano-solid spheres of the product obtained according to this embodiment.

Embodiment 3

[0037] Nano-sized monoclinic VO 2 (VO 2 (M)) Realization of powder material nanoribbons: add 1mmol VOSO to a 250mL glass jar 4 The powder is added to 100mL organic solvent toluene, and the combustion environment temperature is around 25°C. Then directly ignite it with an open flame for about half an hour and the reaction is complete. The obtained sample can be washed with pure water. Figure 5 It is a nanobelt FE-SEM photo of the product obtained according to this embodiment.

[0038] From the photographs of the nanonized products obtained in Examples 2 and 3, the particle shape of the obtained products is regular, the size range is small, and it can have better industrial applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com