Method for crudely extracting pleocidin

A spinosad, crude extraction technology, applied in the direction of chemical instruments and methods, biocides, chemicals for biological control, etc., can solve the problems of adsorption rate requirements, leakage, product purity not clearly stated, etc., to improve Recovery rate, organic solvent saving, effect of small elution volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

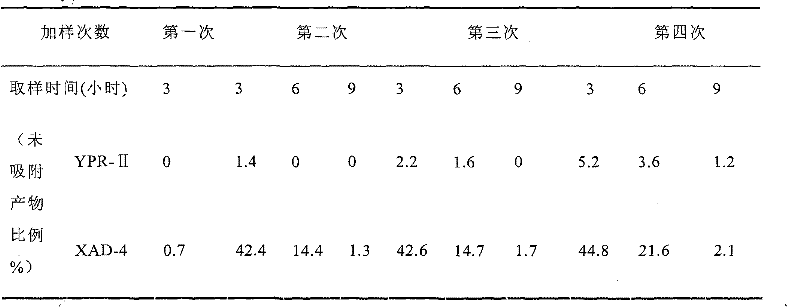

[0033] Embodiment 1: Static experiment compares adsorption resin:

[0034] Take 20ml each of the treated YPR-II and XAD-4 macroporous adsorption resins, put them into 750ml Erlenmeyer flasks respectively, then add 200ml of pretreated fermentation broth, place them on a shaking table at 28°C and 150r / min to vibrate and adsorb, Samples were taken at 3, 6, and 9 hours for HPLC titer determination. A total of 4 samples were added, and the volume of the fermentation broth added each time was 200ml. in,

[0035] Ratio of unadsorbed product = (sampling titer after adsorption / fermentation broth titer after pretreatment) × 100%

[0036] Table 2

[0037]

[0038] Table 2 shows that compared with XAD-4 resin, YPR-II resin has a faster adsorption rate and can achieve complete adsorption in a shorter time.

Embodiment 2

[0039] Embodiment 2: Adopt YPR-II resin to adsorb the fermentation broth after spinosad pretreatment, investigate the influence of pH on adsorption

[0040] 1) Adjustment of fermentation broth and resin column pH:

[0041] After pretreatment of the fermented liquid obtained according to the existing literature, each get 200ml, adjust the pH to 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, 11.0 respectively; get every 20ml of processed resin to pack into a resin column, and then Rinse the YPR-II resin column with acetone that has adjusted the corresponding pH, so that the pH of the resin reaches the pH of the pre-column fermentation broth, that is, resins with pHs of 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, and 11.0 column.

[0042] 2) Upper column:

[0043] Adsorb with corresponding pH resin columns on the pH-adjusted fermentation broth, collect in units of 50 ml, and detect the leakage rate by HPLC. in:

[0044] Leakage rate (%) = potency of each collection unit / potency of fermentation ...

Embodiment 3

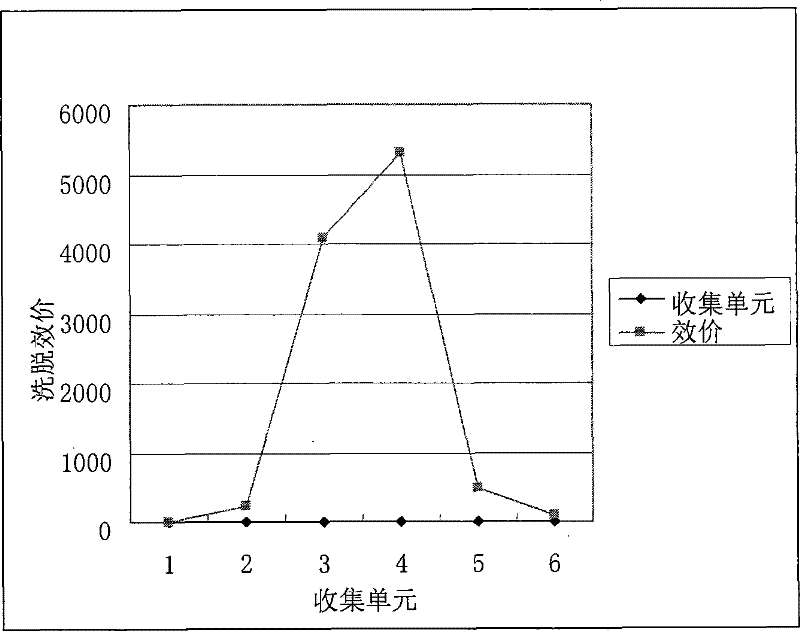

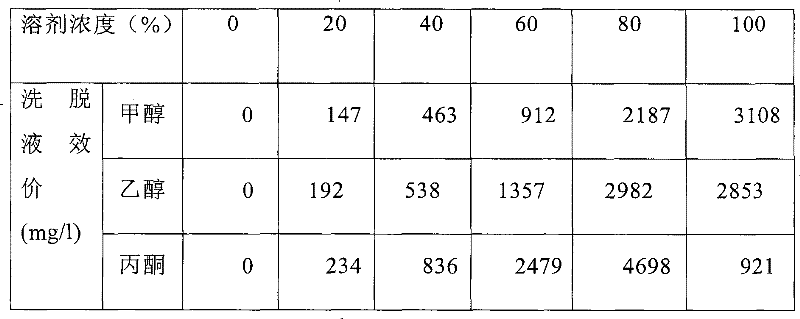

[0050] Example 3: Comparison of eluents

[0051] Take 20ml of the adsorbed YPR-II resin and fix it in a column, then use 0%, 20%, 40%, 60%, 80%, 100% acetone and methanol to elute, and use 200ml of each concentration solution volume, and the eluate was collected as a unit for HPLC titer determination. The results are shown in Table 4 below:

[0052] Table 4

[0053]

[0054] As can be seen from the above table 4, the elution ability of acetone is stronger than that of methanol and acetone, and the highest peak can be reached when the concentration is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com